AD104-R2, AD104-R5 7 / 75

ba_aed104_8_e.doc

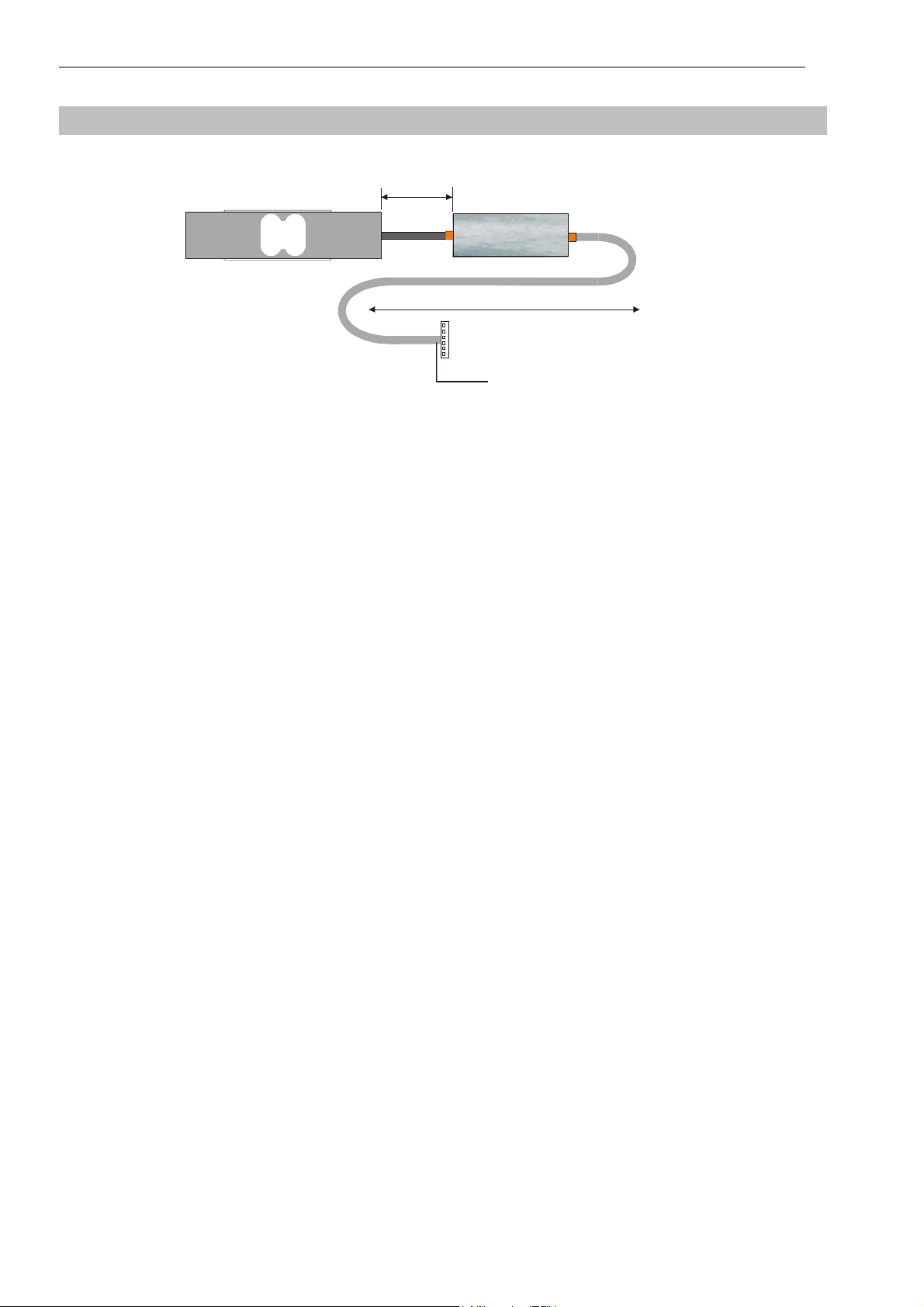

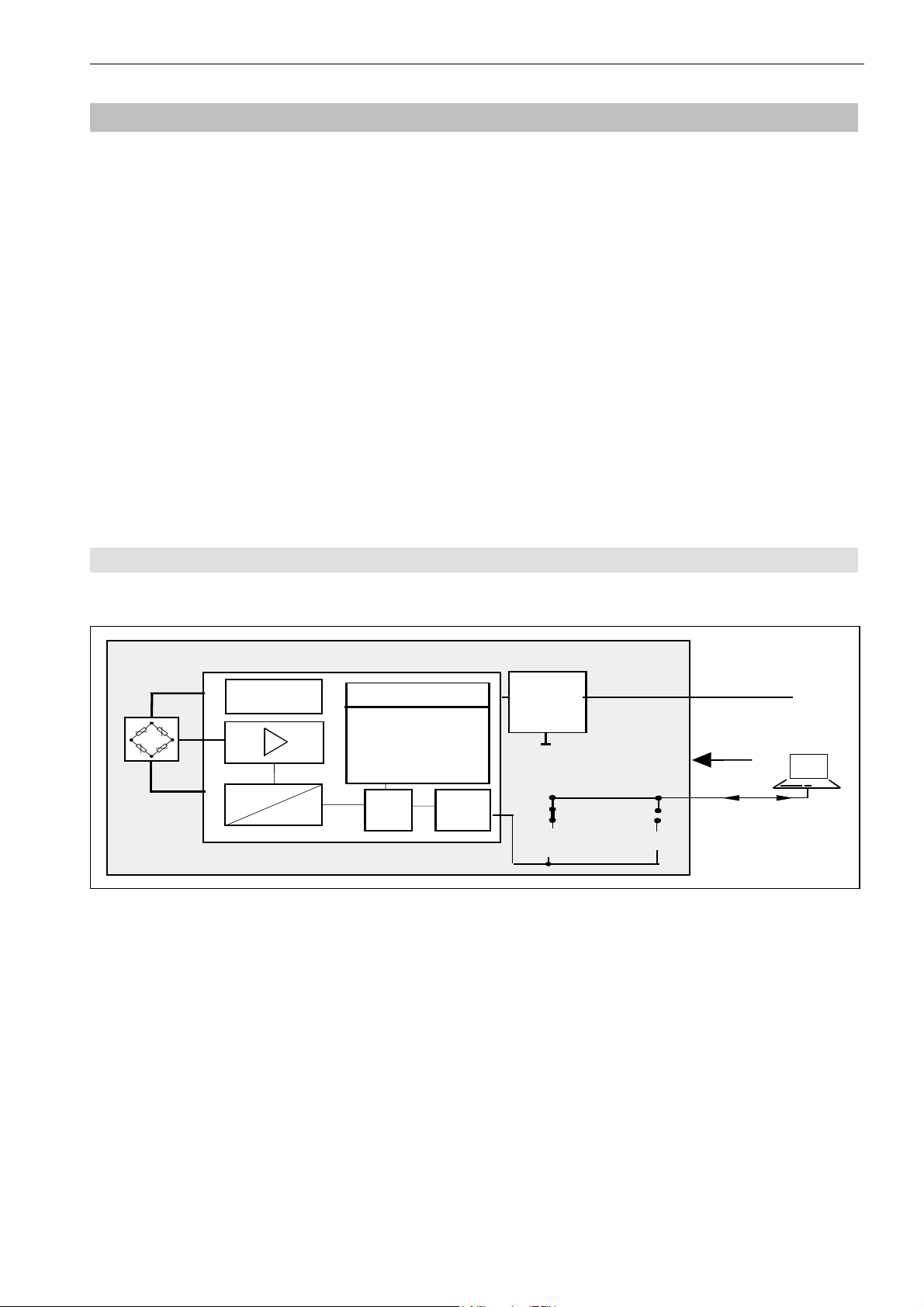

The AD104 comprises two trigger functions in order to support functions in packaging machines and

checkweigher:

•triggering by means of an adjustable level (gross and net measured value, for both types)

•external triggering by means of a trigger input

This special measuring mode is activated by means of the command TRC. The measured value determined is

output by means of the command MAV?. For this measuring mode, filter mode FMD1 should be set (fast

settling time).

The measuring speed depends on the preset stop time and the measuring period. The stop time should match

the fast transient recovery of the filter used (ASF).

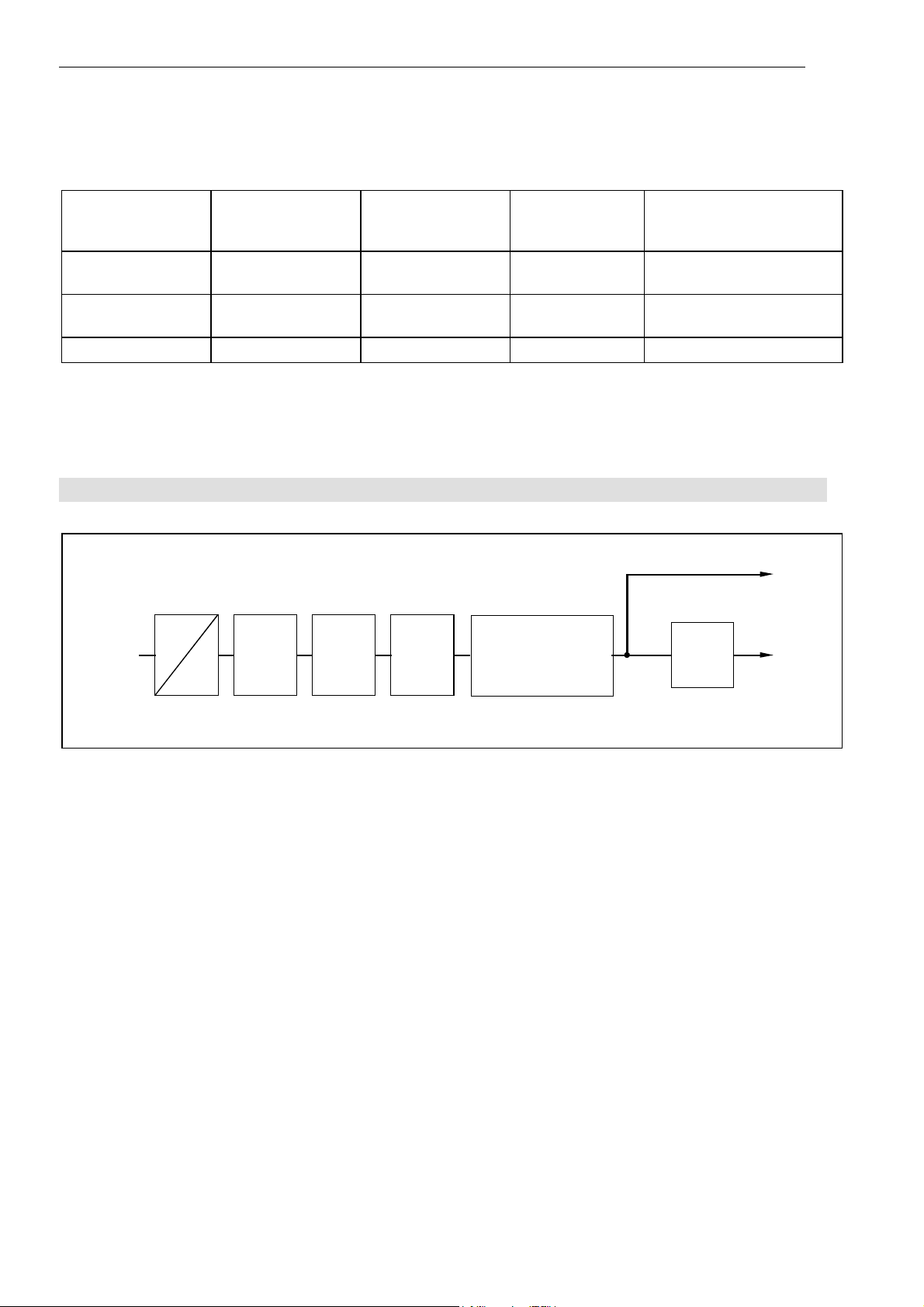

Level triggering:

This measuring mode is suitable for weighing processes where the scale is relieved in between weighing

events.

The scale is in a no load condition. The material to be weighed will be placed on the scale, the trigger level is

exceeded, and stop time measurement starts. On expiry of this transient period, the actual weight will be

determined; and on expiry of this measuring period, the actual weight value will be stored in memory. The

weighing process can be restarted only once the weight value is again lower than the trigger level (place scale

in no load condition). In this measurement mode, weight determination does not need to be monitored by an

external computer at high speed. The output memory will contain an invalid value until a new measured value

has been created. After retrieving the contents of the measured value memory by means of the MAV?

command, this memory is reset to an invalid condition (invalid value < - 1600 000).

The periods (stop time and measurement period x 10ms at ICR0) and the trigger level can be freely set by

means of the command TRC. The trigger level will be on the user characteristic (NOV).

External trigger:

Both types support an external trigger instead of the limit value trigger. This trigger has a quiescent signal level

at 0V (=low) and uses the low/high edge to activate the measurement process.

The trigger flank starts the stop time measurement. On expiry of this transient period, the actual weight will be

determined over the measurement period, and the averaged actual weight value will be stored in memory. The

output memory will contain an invalid value until a new measured value has been created. After retrieving the

contents of the measured value memory by means of the MAV? command, this memory is reset to an invalid

condition. The periods (stop time and measurement period x 10ms at ICR0) and the trigger level can be freely

set by means of the command TRC. A renewed trigger flank will restart the measurement process. The scale

does not need to be placed into a no load condition.

During a measuring (waiting time + measuring time) a trigger signal is unvalid (no re-triggering). Within this

mode the parameter trigger level (P3) has no function.

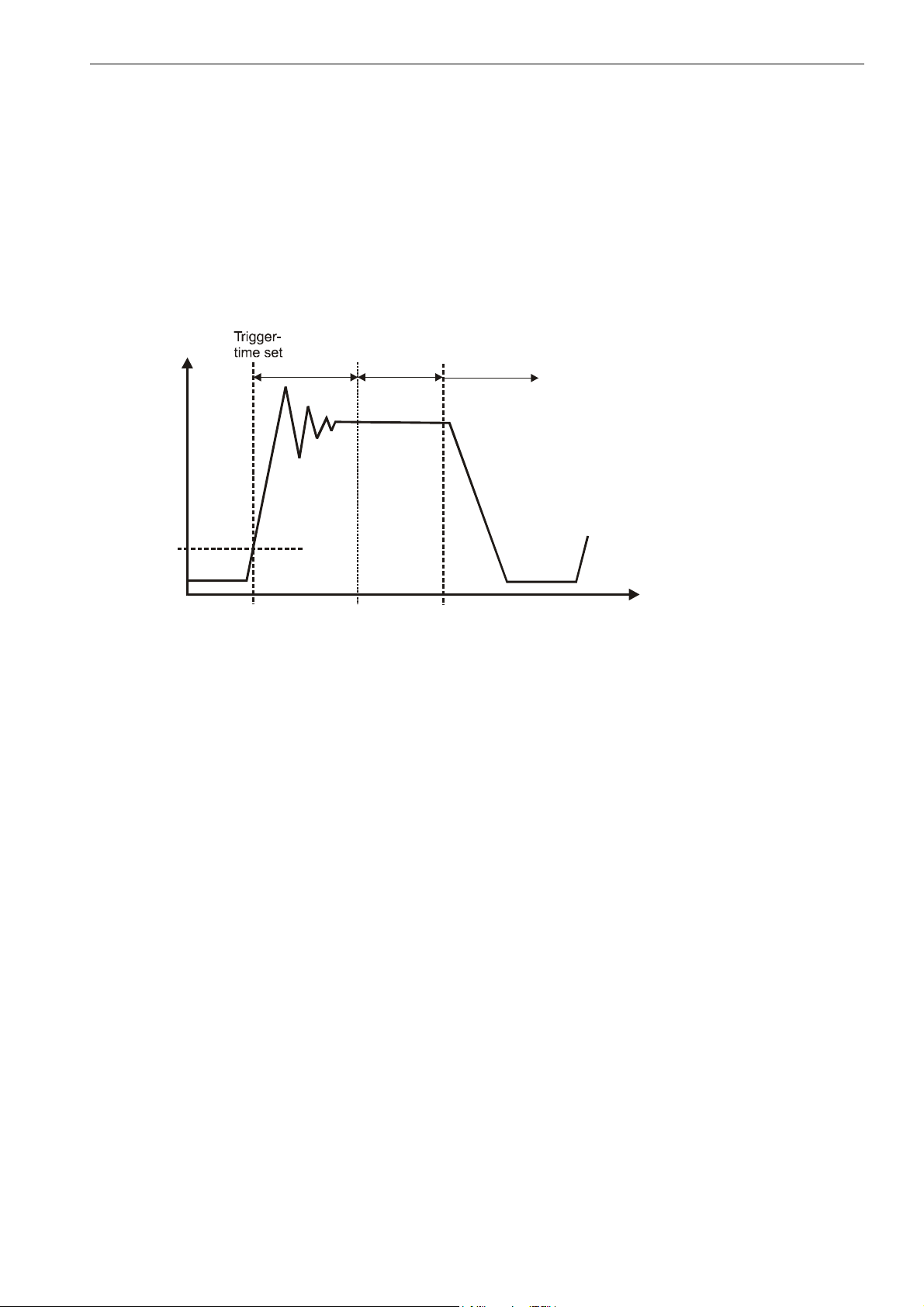

Tr a n s. Re c o v.

time

TRC-command

Parameter 4

Measuring time

TRC-command

Parameter 5

Weig ht

Time

Triggering

(TRC-Command: Parameter 1=1)

Trigger level

TRC-comm.

Parameter 3

if P2=0

Result in output memory