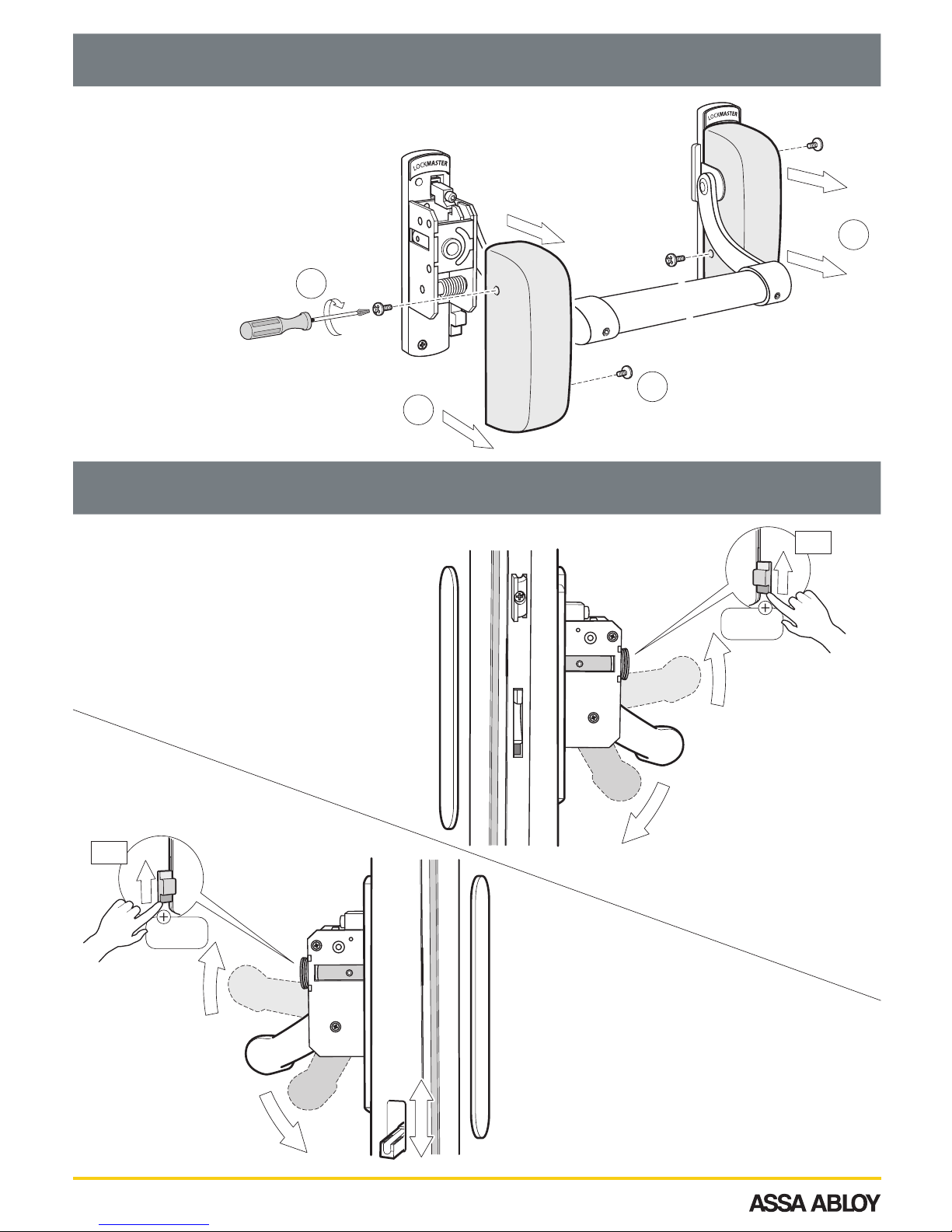

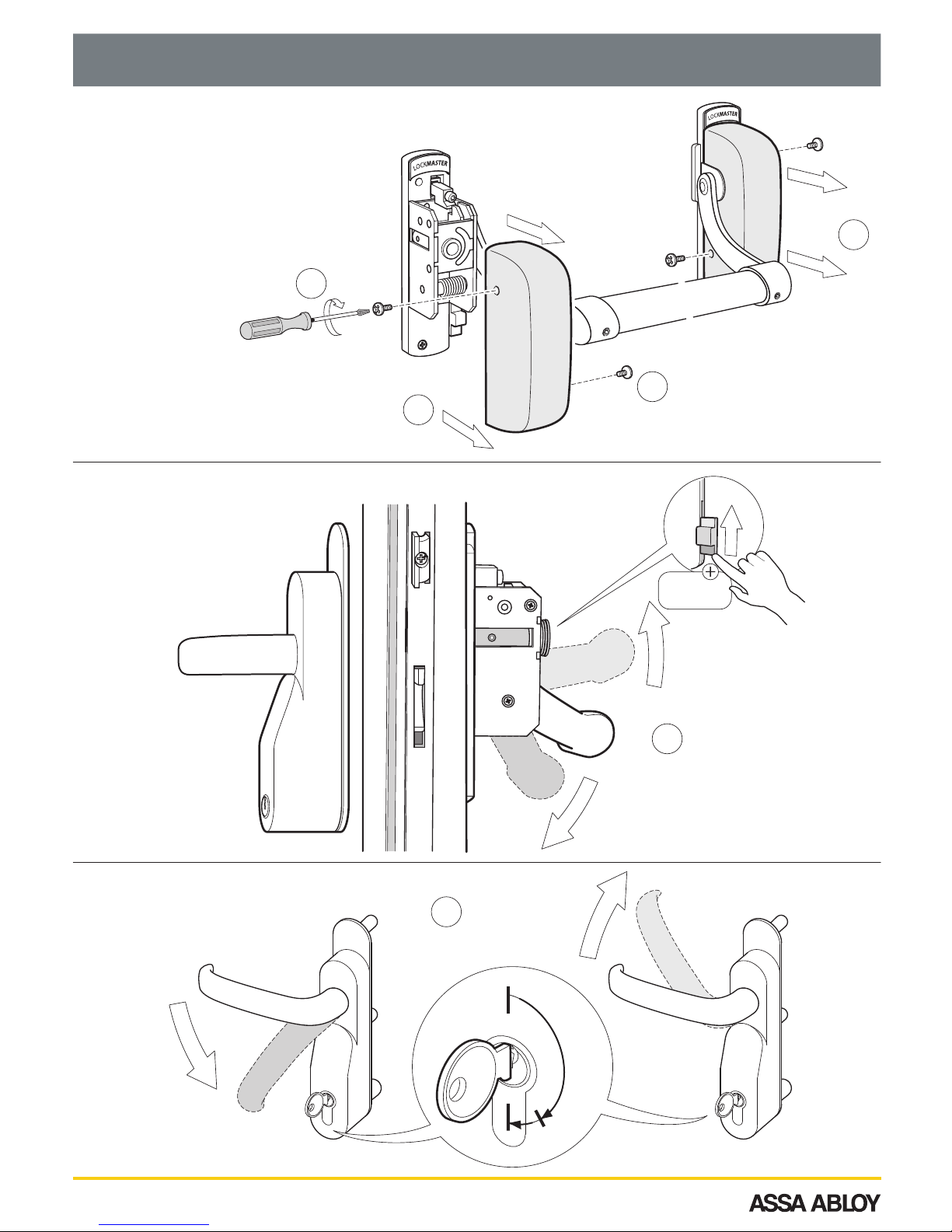

INSTALLATION AND FIXING INSTRUCTIONS

5. On double doorsets with rebated meeting stiles and where both leaves are fitted with exit devices, it is essential to

check that either leaf will open when its respective device is activated and also that both leaves will open freely when

both exit devices are operated simultaneously.

6. Where exit devices are manufactured in more than one size please ensure the correct size is selected.

7. Category 2 (standard projection) exit devices should be used in situations where there is restricted width for escape,

or where the doors are not able to open beyond 90º

8. Where a device is fitted to a glazed door, it is essential that the glazing should be toughened or laminated glass.

9. Alternative fixing screws may be necessary for fitting devices to wood, metal, PVC-U or frameless glass doors.

For more secure fixing, male and female through-door bolts can be used.

10. Exit devices are not intended for use on double action (double swing) doors unless specifically designed by the

manufacturer.

11. The installation instructions must be carefully followed during installation. These instructions and maintenance

booklet should be handed over to the end user, building occupier or the authorised representative after completion.

12. Normally the operating element (push bar or touch bar) should be installed at a height of between 900mm and

1100mm above the finished floor level, when the door is in the secured position. Where it is known that the majority

of the occupants of the premises will be young children, consideration should be given to reduce the height.

13. For panic devices the horizontal bar should be installed so as to provide the maximum effective length (never less than

60% of the door width)

14. The bolt heads, latches and strikers/keepers should be fitted so as to provide secure engagement. Care should be

taken to ensure that no projection of the bolt heads or latches, when in the withdrawn position, could prevent the

door swinging freely.

15. Where panic devices are to be fitted to double doorsets with rebated meeting stiles and self-closing devices, a door

coordinator device according to EN1158 should be fitted to ensure the correct closing sequence of the doors.

Note: This recommendation is particularly important with regard to fire/smoke door assemblies.

16. No additional devices for securing the door in the closed position other than specified herein should be fitted.

This does not preclude the installation of self-closing devices.

17. If a door closing device is to be used to return the door to the closed position, care should be taken not to impair the

use of the doorway by the young, elderly and infirm.

18. Only strikers or keeps plates provided by the manufacturer should be fitted in order to ensure compliance with the

European Standards.

19. For BS EN1125 a sign which reads “push bar to open” or a pictogram should be

provided on the inside face of the door immediately above the horizontal bar.

The surface area of the pictogram should be no less than 8000mm² and its colours

should be white on green background. It should be designed such that the arrow

points to the operating element when installed. (see example of pictogram)

It is hereby declared that this device was installed according to the

manufacturers instructions

................................................................ Signature and Stamp of Installer

Installation and Maintenance Requirements

for Panic Exit Devices

European Patent Application No. 09155542.5

(07)

An ASSA ABLOY Group brand

Maintenance Log Book, page 2