9

English Español Português

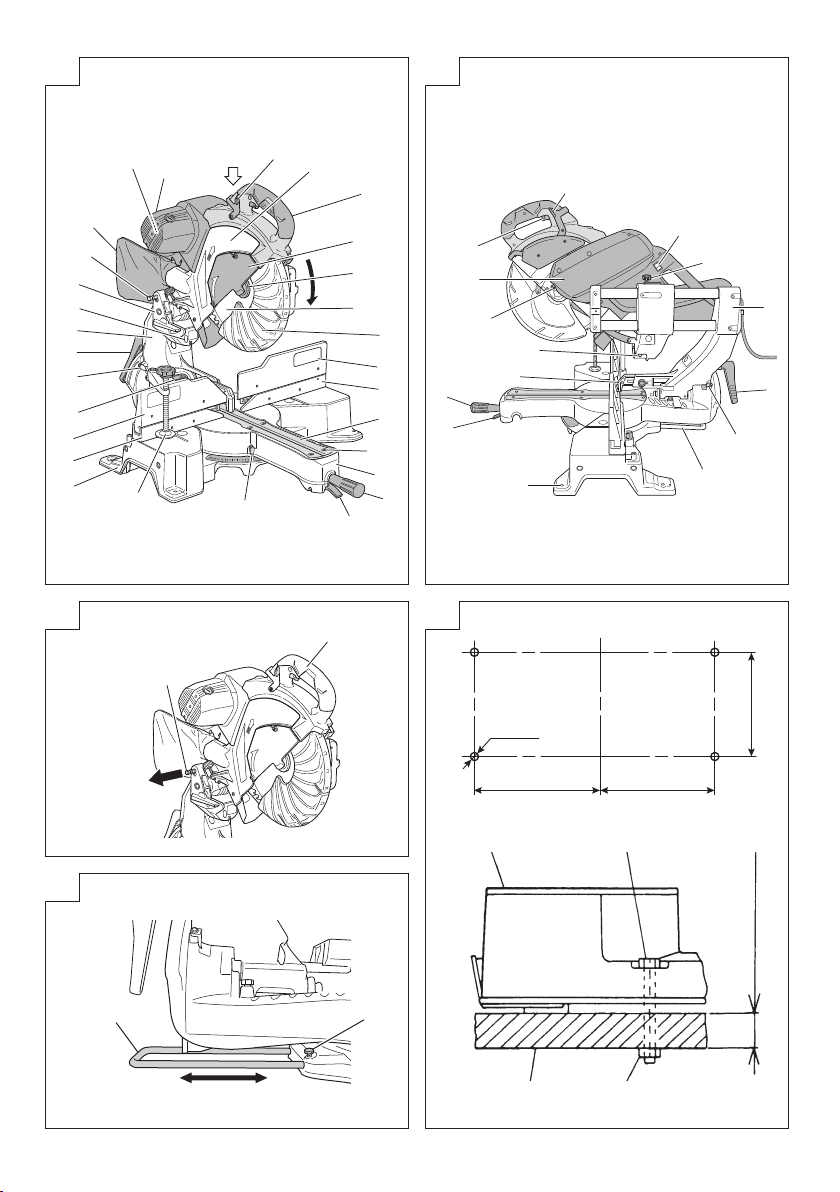

bHolder (Optional accessory) Soporte (Accessorio opcionales) Suporte (Acessório opcional)

nSteel Square Escuadra de acero Esquadro de aço

m6 mm Wing Nut

(Optional accessory) Tuerca de aletas de 6 mm

(Accesorio opcional) Porca-borboleta de 6 mm

(Acessório opcional)

,Height Adjustment Bolt 6 mm

(Optional accessory) Perno de ajuste de altura de 6 mm

(Accesorio opcional) Parafuso de ajuste de altura de 6 mm

(Acessório opcional)

.Base Surface Superficie de la base Superfície da base

/Stopper (Optional accessory) Retén (Accessorio opcionales) Batente (Acessório opcional)

¡6 mm Knob Bolt

(Optional accessory) Perno de perilla de 6 mm

(Accesorio opcional) Parafuso de botão de 6 mm

(Acessório opcional)

™Sub Fence (A) Tope-guía secundario (A) Subguia (A)

£6 mm Nut Tuerca 6 mm Porca de 6 mm

¢Screw Holder Sujetador de rosca Suporte de parafuso

∞Hex. socket set screw Tornillo de fijación con cabeza

hexagonal Parafuso de ajuste com sextavado

interno

§Vise Shaft Eje de tornillo de banco Eixo do torno

¶Duct Conducto Conduto

•Fence Protrección Guia

ª6 mm Wing Bolt 6 mm perno de ala Parafuso-borboleta de 6 mm

ºVise Plate Placa de tornillo Placa do torno

⁄Knob Perilla Botão

¤Laser line Línea de láser Linha de laser

‹Groove Ranura Ranhura

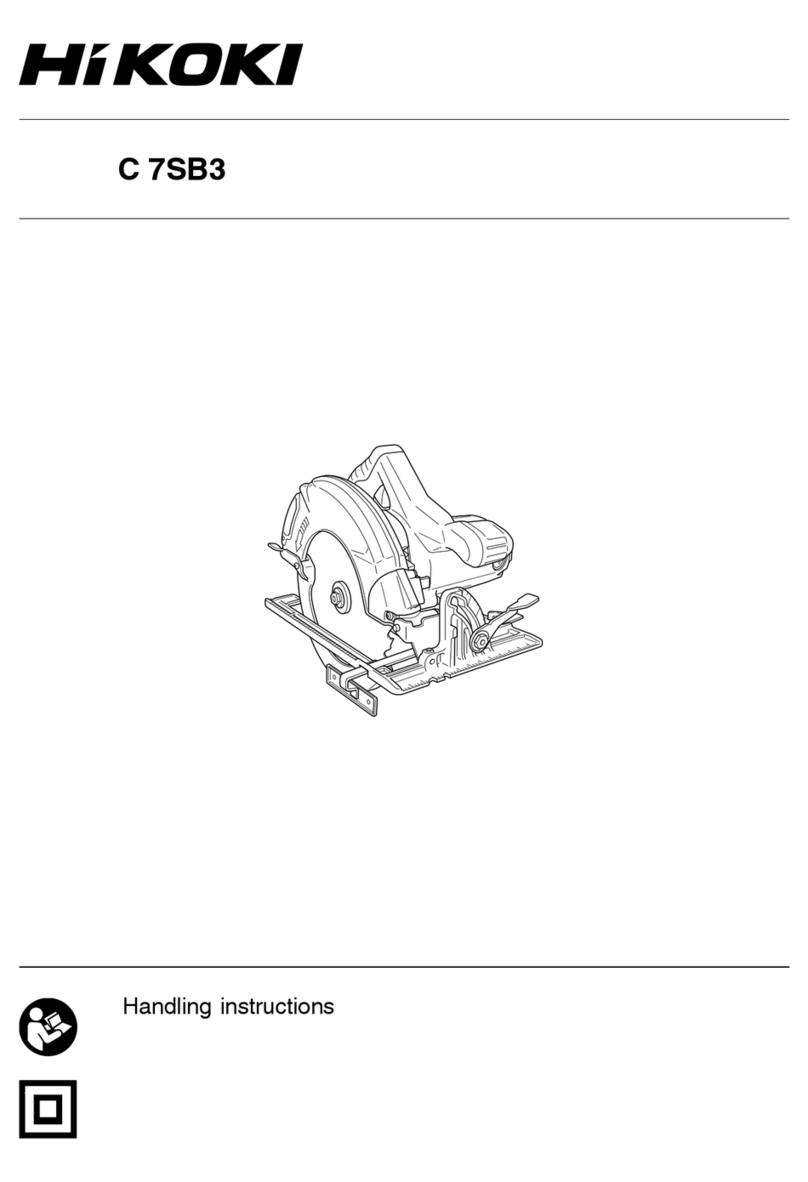

›Bevel Scale Escala en bisel Escala de bisel

fiMiter Scale Escala de ingletes Escala de esquadria

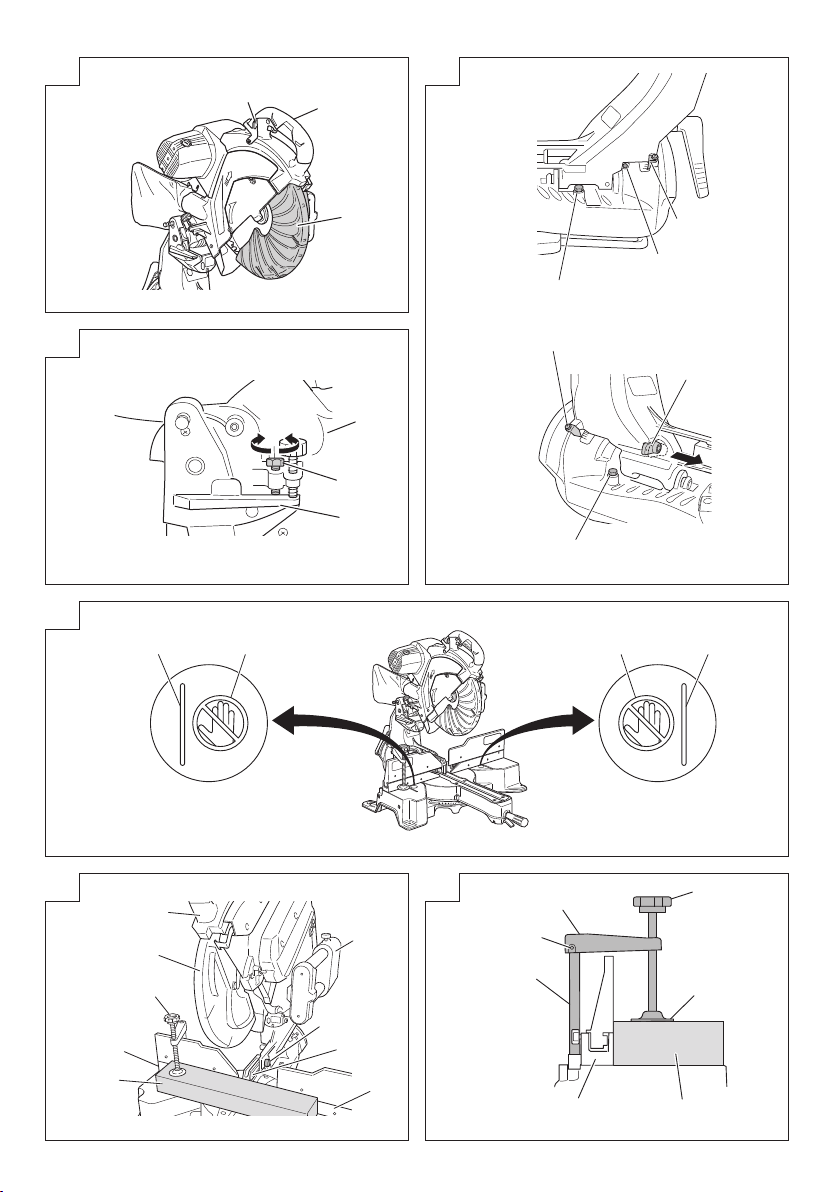

flCrown molding Vise Ass’y

(Optional accessory)

Conj. de tornillo de carpintero para

moldura en vértice (Accesorio opcional)

Conjunto de torno para moldura em

coroa (Acessório opcional)

‡6 mm Wing Nut

(Optional accessory) Tuerca de aletas de 6 mm

(Accesorio opcional) Porca-borboleta de 6 mm

(Acessório opcional)

°Crown molding Stopper (L)

(Optional accessory) Retén de moldura en vértice (L)

(Accesorio opcional) Batente de moldura em coroa (L)

(Acessório opcional)

·Crown molding Stopper (R)

(Optional accessory) Retén de moldura en vértice (R)

(Accesorio opcional) Batente de moldura em coroa (R)

(Acessório opcional)

‚Crown molding Moldura en vértice Moldura em coroa

Œ17 mm Box Wrench Lllave de tubo de 17 mm Chave de boca de 17 mm

„10 mm Bolt Perno de 10 mm Parafuso de 10 mm

´Washer (A) Arandela (A) Arruela (A)

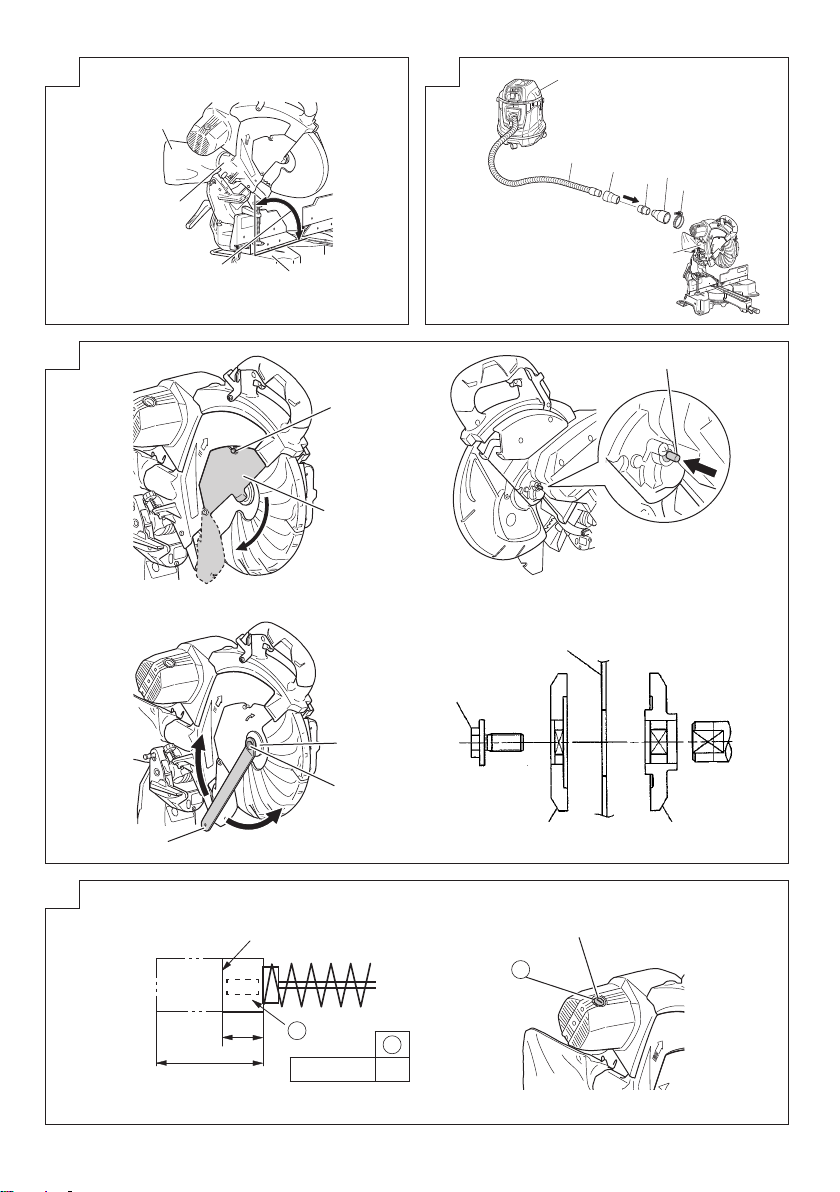

‰Wear limit line Línea de límite de desgaste Linha de limite de desgaste

ˇ6 mm Knob Bolt Perno de perilla de 6 mm Parafuso de botão de 6 mm

ÁRight angle Ángulo recto Ângulo reto

¨Dust extractor Extractor de polvo Extrator de pó

îHose (id 38 mm × 3 m long) Manguera

(id 38 mm × 3 m de longitud) Mangueira

(D.I.= 38 mm × 3 m de comprimento)

ØAdapter (Dust extractor's standard

accessory) Adaptador (accesorio estándar del

extractor de polvo) Adaptador

(Acessório padrão de extrator de pó)

∏Joint (Optional accessory) Acople (Accesorio opcional) Junta (Acessório opcional)

ÅDust collection adapter

(Optional accessory) Adaptador de recolección de polvo

(Accesorio opcional) Adaptador de coleta de pó

(Acessório opcional)

ÍHose band (Optional accessory) Abrazadera (Accesorio opcional) Braçadeira de mangueira

(Acessório opcional)

ÎMarking (pre-marked) Marcaje (pre-marcado) Marcação (pré-marcado)

ÏLine Línea Linha

0000BookC12RSH2SA.indb90000BookC12RSH2SA.indb9 2018/02/0915:16:352018/02/0915:16:35