80

Code No. C99169371

Printed in China

Handling instructions

Bedienungsanleitung

Mode d’emploi

Instruzioni per l’uso

Gebruiksaanwijzing

Instrucciones de manejo

Instruções de uso

Read through carefully and understand these instructions before use.

Diese Anleitung vor Benutzung des Werkzeugs sorgfältig durchlesen und verstehen.

Lire soigneusement et bien assimiler ces instructions avant usage.

Prima dell’uso leggere attentamente e comprendere queste instruzioni.

Deze gebruiksaanwijzing s.v.p. voor gebruik zorgvuldig doorlezen.

Leer cuidadosamente y comprender estas instrucciones antes del uso.

Antes de usar, leia com cuidado para assimilar estas instruções.

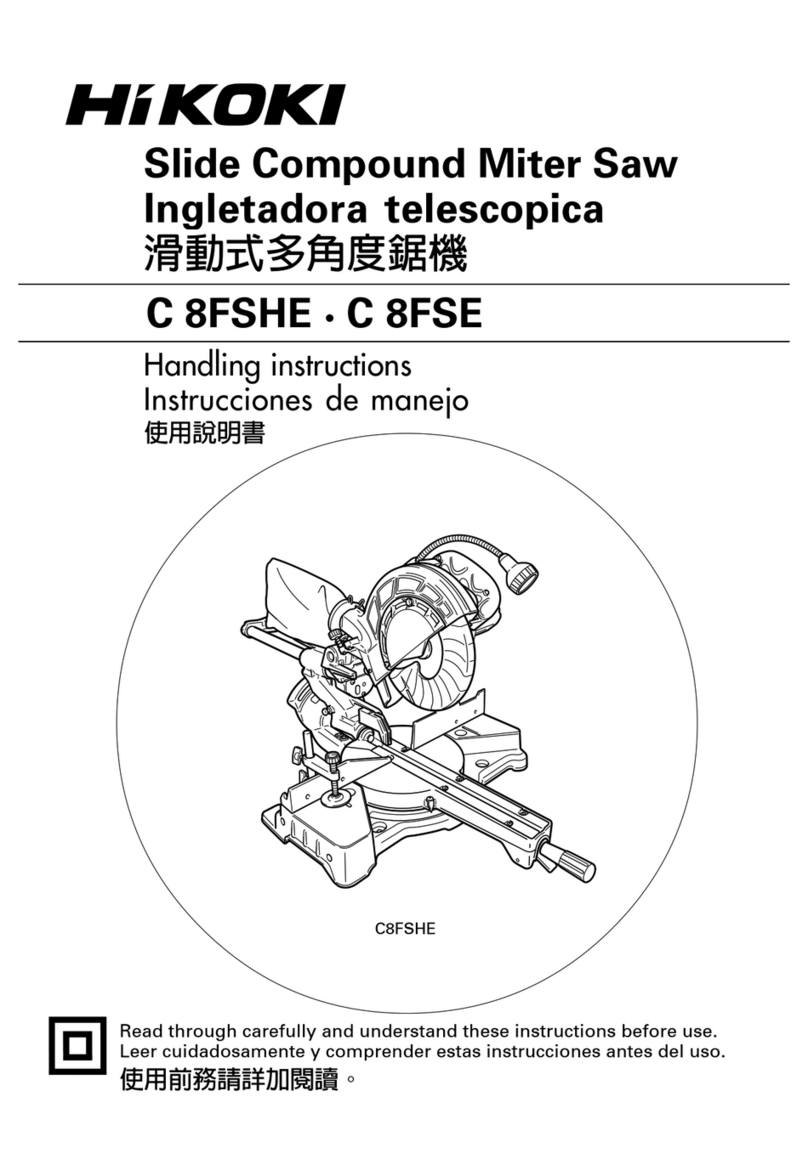

Slide Compound Miter Saw

Paneelsäge

Scie radiale à coupe d'onglet

Troncatrice da legno

a taglio assiale e radiale

Afkortzaagmachine met

telescopisch zaagarm

Ingletadora telescopica

Serra telescópica

C 8FSHE • C 8FSE

1

12

34

56

78

3

W

^

7

4

B

H

c

4

7

6

7

8

A

C

D

FG

H

I

J

K

L

B

5

9

M

1

2

4N

0

[

\

]

O

Q

5

U

V

W

XY

]

1

21

L

m

n n m

c

P

Representative office in Europe

Hitachi Power Tools Europe GmbH

Siemensring 34, 47877 Willich 1, F. R. Germany

Head office in Japan

Hitachi Koki Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

31. 1. 2008

K. Kato

Board Director

Nederlands

EC VERKLARING VAN CONFORMITEIT

Wij verklaren onder eigen verantwoordelijkheid dat dit

produkt conform de richtlijnen of gestandardiseerde

documenten EN61029, EN55014 en EN61000-3 voldoet

aan de eisen van EEG Bepalingen 73/23/EEG, 2004/108/

EC en 98/37/EC.

Deze verklaring is van toepassing op produkten

voorzien van de CE-markeringen.

Español

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra única responsabilidad que

este producto está de acuerdo con las normas o con

los documentos de normalización EN61029, EN55014

y EN61000-3, según indican las Directrices del Consejo

73/23/CEE, 2004/108/CE y 98/37/CE.

Esta declaración se aplica a los productos con marcas

de la CE.

Português

DECLARAÇÃO DE CONFORMIDADE CE

Declaramos, sob nossa única e inteira responsabilidade,

que este produto está de acordo com as normas ou

documentos normativos EN61029, EN55014 e EN61000-

3, em conformidade com as Diretrizes 73/23/CEE, 2004/

108/CE e 98/37/CE do Conselho.

Esta declaração se aplica aos produtos designados CE.

English

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that this

product is in conformity with standards or standardized

documents EN61029, EN55014 and EN61000-3 in

accordance with Council Directives 73/23/EEC, 2004/108/

EC and 98/37/EC.

This declaration is applicable to the product affixed CE

marking.

Deutsch

ERKLÄRUNG ZUR KONFORMITÄT MIT CE-REGELN

Wir erklären mit alleiniger Verantwortung, daß dieses

Produkt den Standards oder standardisierten

Dokumenten EN61029, EN55014 und EN61000-3 in

Übereinstimmung mit den Direktiven des Europarats 73/

23/EWG, 2004/108/CE und 98/37/CE entspricht.

Diese Erklärung gilt für Produkte, die die CE-Markierung

tragen.

Français

DECLARATION DE CONFORMITE CE

Nous déclarons sous notre seule et entière

responsabilité que ce produit est conforme aux normes

ou documents normalisés EN61029, EN55014 et

EN61000-3 en accord avec les Directives 73/23/CEE,

2004/108/CE et 98/37/CE du Conseil.

Cette déclaration s’applique aux produits désignés CE.

Italiano

DICHIARAZIONE DI CONFORMITÀ CE

Si dichiara sotto nostra responsabilità che questo

prodotto è conforme agli standard o ai documenti

standardizzati EN61029, EN55014 e EN61000-3

conforme alle direttive 73/23/CEE, 2004/108/CE e 98/37/

CE del concilio.

Questa dichiarazione è applicabile ai prodotti cui sono

applicati i marchi CE.

C8FSHE

English Nederlands

EC DECLARATION OF CONFORMITY

We declare under our sole responsibility that Slide Compound

Miter Saw, identified by type and specific identification code *1), is

in conformity with all relevant requirements of the directives *2) and

standards *3). Technical file at *4) – See below.

The European Standard Manager at the representative office in

Europe is authorized to compile the technical file.

The declaration is applicable to the product affixed CE marking.

EC VERKLARING VAN CONFORMITEIT

Wij verklaren onder onze eigen verantwoordelijkheid dat

Afkortzaagmachine met telescopisch zaagarm, geïdentificeerd

door het type en de specifieke identificatiecode*1), voldoet aan alle

relevante bepalingen van de richtlijnen*2) en normen*3). Technische

documentatie bij*4) – zie onder.

De Europese Normen Manager bij de vertegenwoordiging in Europa

is gemachtigd om het technisch dossier samen te stellen.

Deze verklaring is van toepassing op producten voorzien van de CE-

markeringen.

Deutsch Español

EG-KONFORMITÄTSERKLÄRUNG

Wir erklären in alleiniger Verantwortung, dass die durch den Typ und

den spezifischen Identifizierungscode *1) identifizierte Paneelsäge

allen einschlägigen Bestimmungen der Richtlinien *2) und Normen

*3) entspricht. Technische Unterlagen unter *4) – Siehe unten.

Die Leitung der repräsentativen Behörde für europäische Normen

und Richtlinien ist berechtigt, die technischen Unterlagen

zusammenzustellen.

Die Erklärung gilt für die an dem Produkt angebrachte CE-

Kennzeichnung.

DECLARACIÓN DE CONFORMIDAD DE LA CE

Declaramos bajo nuestra única responsabilidad que la Ingletadora

telescópica, identificada por tipo y por código de identificación

específico *1), está en conformidad con todas las disposiciones

correspondientes de las directivas *2) y de las normas *3).

Documentación técnica en *4) – Ver a continuación.

El Director de Normas Europeas en la oficina de representación en

Europa está autorizado para elaborar el expediente técnico.

La declaración se aplica al producto con marcas de la CE.

Français Português

DECLARATION DE CONFORMITE CE

Nous déclarons sous notre entière responsabilité que la scie radiale

à coupe d'onglet, identifiée par le type et le code d'identification

spécifique *1) est en conformité avec toutes les exigences applicables

des directives *2) et des normes *3). Dossier technique en *4) - Voir

ci-dessous.

Le Gestionnaire des normes européennes du bureau de représentation

en Europe est autorisé à constituer le dossier technique.

Cette déclaration s'applique aux produits désignés CE.

DECLARAÇÃO DE CONFORMIDADE CE

Declaramos, sob nossa única e inteira responsabilidade, que Serra

Telescópica, identificada por tipo e código de identificação específico

*1), está em conformidade com todos os requerimentos relevantes

das diretivas *2) e normas *3). Ficheiro técnico em *4)–Consulte

abaixo.

O Gestor de Normas Europeias no escritório de representação na

Europa está autorizado a compilar o ficheiro técnico.

A declaração aplica-se aos produtos com marca CE.

Italiano

DICHIARAZIONE DI CONFORMITÀ CE

Dichiariamo sotto la nostra esclusiva responsabilità che la troncatrice

da legno a taglio assiale e radiale, identificata dal tipo e dal codice

identificativo specifico *1), è conforme a tutti i requisiti delle direttive

*2) e degli standard *3). Documentazione tecnica presso *4) – Vedere

sotto.

Il gestore delle norme europee presso l’ufficio di rappresentanza in

Europa è autorizzato a compilare il fascicolo tecnico.

La dichiarazione è applicabile ai prodotti cui sono applicati i marchi

CE.

*1) C8FSE C336174S C336173M

*2) 2006/42/EC, 2014/30/EU, 2011/65/EU

*3) EN61029-1:2009+A11:2010

EN61029-2-9:2012+A11:2013

EN55014-1:2006+A1:2009+A2:2011

EN55014-2:1997+A1:2001+A2:2008

EN61000-3-2:2014

EN61000-3-3:2013

*4) Representative office in Europe

Hikoki Power Tools Deutschland GmbH

Siemensring 34, 47877 Willich, Germany

Head office in Japan

Koki Holdings Co., Ltd.

Shinagawa Intercity Tower A, 15-1, Konan 2-chome,

Minato-ku, Tokyo, Japan

29. 6. 2018

Naoto Yamashiro

European Standard Manager

29. 6. 2018

A. Nakagawa

Corporate Officer

806

Code No. C99169371 F

Printed in China