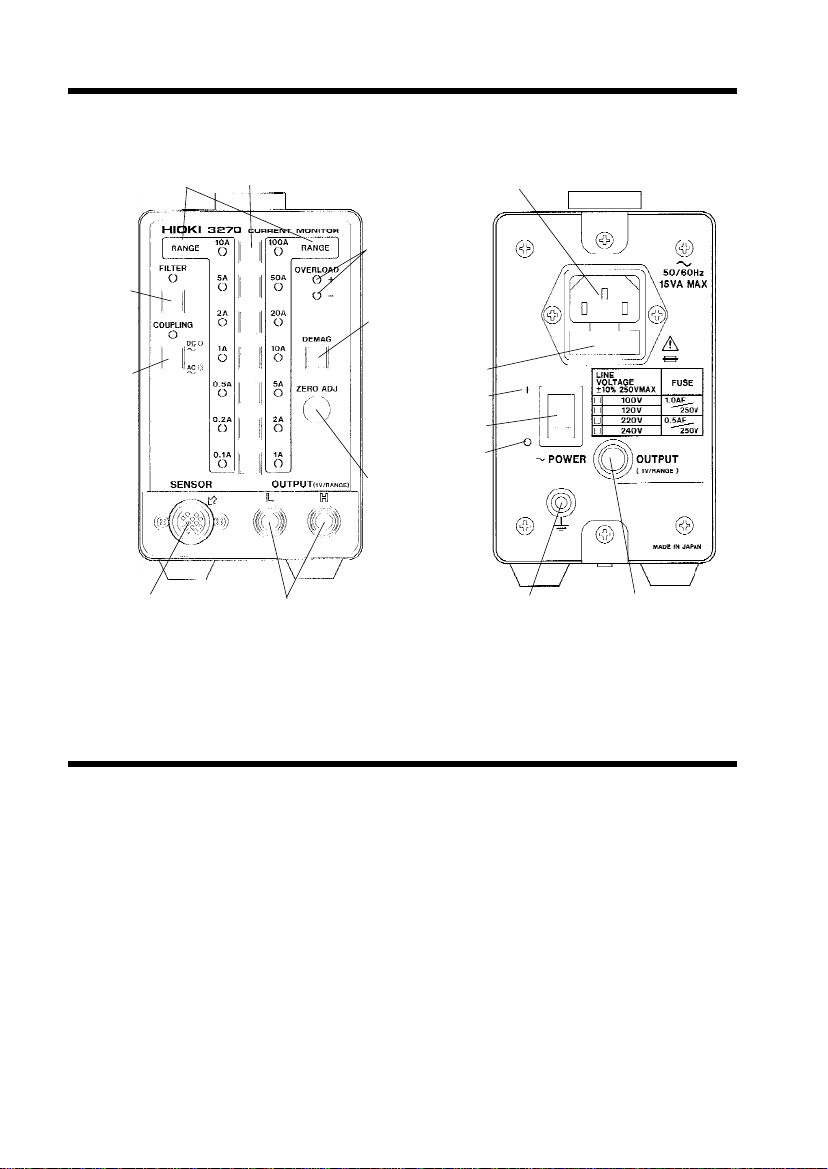

Hioki 3270 User manual

Other Hioki Measuring Instrument manuals

Hioki

Hioki IM3523A User manual

Hioki

Hioki RM3545 User manual

Hioki

Hioki 9605-01 User manual

Hioki

Hioki 3143 User manual

Hioki

Hioki lr5001 User manual

Hioki

Hioki IM3523 User manual

Hioki

Hioki LR8400-92 User manual

Hioki

Hioki CM4371-50 User manual

Hioki

Hioki Memory HiCorder MR6000 User manual

Hioki

Hioki CT6700 User manual

Hioki

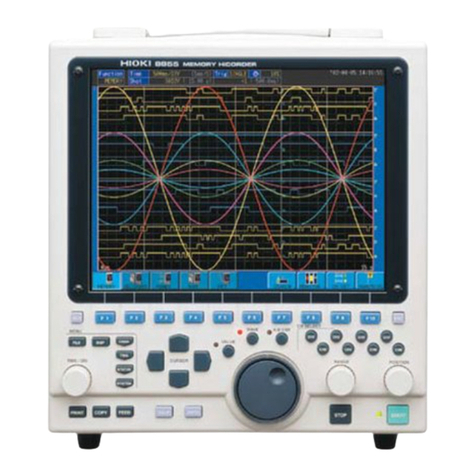

Hioki MEMORY HiCORDER 8855 Manual

Hioki

Hioki 3197 User manual

Hioki

Hioki PR8111 User manual

Hioki

Hioki 3662-20 User manual

Hioki

Hioki CM4373-50 User manual

Hioki

Hioki PW3335 User manual

Hioki

Hioki 3227 User manual

Hioki

Hioki MR8740 User manual

Hioki

Hioki 3196 User manual

Hioki

Hioki HiTester 3443-01 User manual