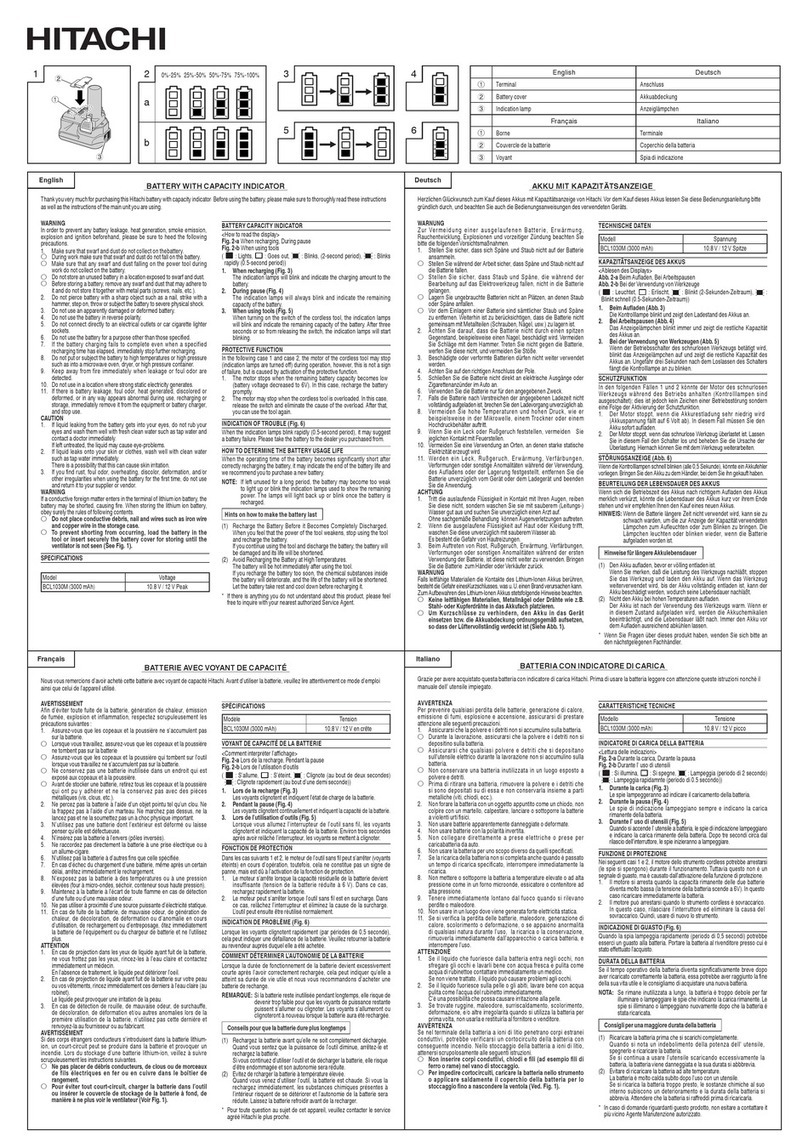

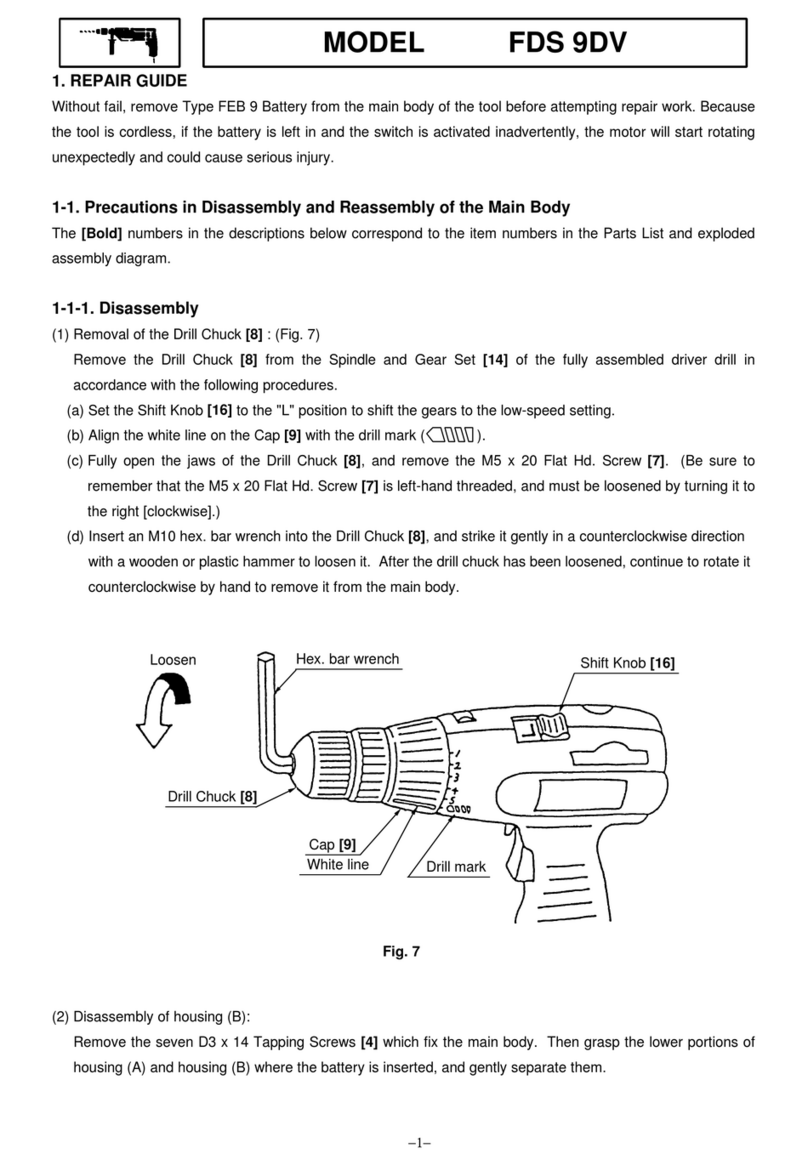

(g) Mount the components assembled as described in Para. (f) onto the components assembled as described

in Para.(e).At this time, ensure that colored leadwires solderedto theTerminal [27] are properly aligned

with relation to housing (A) and housing, (B). (See Fig. 16)

(4) Other Precautions on Reassembly

(a) On completion of reassembly, set the Shift Knob[16] to the "H" position, and confirm that the spindle

rotates smoothly when the Drill Chuck [8]is moved byhand. Also,before turning the switch ON, confirm

that the Cap [9]can be properly aligned with the clutch number positions, marked on the Housing (A),(B)

Set[3].

Confirm that the Drill Chuck [8] rotation conforms with the setting position of the reversing switch. When

the reversing switch is set tothe (R) side, theDrill Chuck [8] must rotateto the right (clockwise) when

viewed from the rear (the end opposite from the drill chuck).

Also, confirm that the rotation speed of the Drill Chuck [8]changes properly between high and low speeds

when the Shift Knob [16] position is changed.

Check the run-out of the Drill Chuck [8]. With a 6 mm test bar (Special Repair Tool J-223-2, Code No.

305713) mounted in the Drill Chuck [8],ensure that run-out is not more than 0.5mm when measured at a

distance of 50 mm from the end of the chuck.

(b) (+) Tapping Screws D3 x 8 [18] 0.59 - 0.78 Nm (6 - 8 kgfcm, 5.2 - 6.9 In-lbs)

(+) Tapping Screws D3 x 14 [4] 0.98 - 1.5Nm (10 - 15 kgfcm, 8.7 - 13.0In-lbs)

(+) FT Screw M3 x 10 [25] 0.88 - 1.1Nm (9 - 11 kgfcm, 7.8 - 9.5 In-lbs)

Flat Hd Screw M5 x 20 [7] 3.9Nm ( 40 kgfcm, 34.7 In-lbs)

Drill Chuck [8] 3.9Nm ( 40 kgfcm, 34.7 In-lbs)

1-2. Precautions inDisassembly andReassembly of the Model UC 12SC charger

For details, concerningthe disassembly, reassembly and precautions in use of the Model UC 12SC charger,

please refer to the Technical Data and Service Manual for the Model UC 12SC charger.

−5−

Internal wire (white)

Housing (A)

Parts assembled in Para. (f )

Internal wire (yellow)

Terminal [27]

Parts assembled in Para. (e)

Fig. 16