function direction light , easy use in dark place .

Push the ”HOLD” button to lock display value, push it again to

1)When measuring voltage ensure that instrument is not

connected or switched to a current or resistance Range, or to the

diode check, Always ensure that the correct terminals are used

for the type of measurement to be made.

2)Use extreme care when measuring voltage above 50V,

especially from sources where high Energy is existed.

3)Avoid making connections to “live” circuits whenever possible.

4)When making current measurements ensure that the circuit

not “live” before opening it in order to connect the test leads.

5)Before making resistance measurements or diode test, ensure

that the circuit under test is De--energized.

6)Always ensure that the correct function and range is selected.

If in doubt about the correct range to use, start whit the highest

7)Extreme care should be taken when using the instrument to

conjunction with a current Transformer connected to the

terminals if an open circuit occurs.

8)Ensure that the test leads and probes are in good condition

with no damage to the insulation.

9)Take care not to exceed the over-lode limits as given in the

10) FUSE FOR REPLACEMENT MUST BE OF THE

11) Before opening the case of the instrument to replace battery,

disconnect the test leads from any external circuit, set the

selector switch to “OFF” position.

3.1 DC Voltage measurement

1)Connect the black test lead to “COM” socket and red lead to

2)Set the selector switch to desired “DCV”position and connect

the probes across the source or load under measurement.

3.2 AC Voltage measurement

1) Connect the black test lead to “COM” socket and red lead to

2) Set the selector switch to desired “ACV”position and

connect the probes across the source or load under

3.3 DC Current measurement

1) Connect the black test lead to “COM” socket and red lead to

2) Set the selector switch to desired current range position.

3) Set the selector switch to desired “DCA”position and

connect the probes across the source or load under

3.4 Resistance and continuity measurement

1) Connect the black test lead to “COM” socket and red lead to

2) Set the selector switch to desired resistance range position

3) Connect the probes across circuit to be tested.

Caution: Ensure that the circuit to be tested is “dead”.

Max. input over-load: 250V RMS And<10sec.

1) Connect the black test lead to “COM” socket and red test

leads to the “VΩ” socket.

2) Set the selector switch to “ ” position .

3) Connect the black and red test probe to cathode (-) and

anode (+) ends of diode to be tested respectively.

3.6 Temperature measurement

Set the selector switch to the ‘TEMP ℃/℉’range and connect

the K type thermocouple’s black test lead to “TEMP-” socket and

red test lead to the “T+” socket.

A. The temperature function shows the random

number at ordinary times, must insert the thermocouple

in temperature test hole while examining temperature. In

order to guarantee the accuracy of the measurement,

need to close Light switch while measuring temperature.

B. This meter in closure WRNM-010 type contact

thermocouple limit temperature is 250 ℃(300 ℃

C. Please don't change the thermocouple at will ,

otherwise we can't guarantee to measure accuracy ;

D. Please don’t importing the voltage in the

3.7 RPM (TACH ) measurement

1). Connect the black test lead to “COM” socket and red test

leads to the “VΩ” socket.

2). Connect the red test probe to “BREAKER POINTS ” or

“ ”terminal of IGNITION CIOL ,and connect the black probe to

“GROUND ”or “ - ” terminal of battery .

3). Set the selector switch to the “TACH” position for 3cyl,4cyl ,

5cyl , 6cyl , 8cyl , according to the engine cylinders .For any

TACH signal with a given frequency , in convention

ignition system :RPM=120×freq÷cyl . in DIS ignition system :

4). Start the engine and read engine RPM .

3.8 DWELL ANGLE measurement

1). Connect the black test lead to “COM” socket and red test

lead to the “VΩ” socket .

2). Connect the red test probe to “BREAKER POINTS ” or

“ ”terminal of IGNITION CIOL ,and connect the black probe to

“GROUND ”or “-” terminal of battery .

3). Set the selector switch to the “DWELL” position for 3cyl,

4cyl , 5cyl , 6cyl , 8cyl , according to the engine cylinders .

4). Start engine the display will show the DWELL ANGLE of

4.1 CARING FOR YOUR MULTIMETER

Your digital multimeter is an example of superior design and

craftsmanship. The following Suggestions will help you care for

the milimeter so you can enjoy it for years.

1). Keep the multimeter dry. If it gets wet , wipe it dry immediately.

Liquids can contain minerals that Can corrode electronic circuits

2). Use and store the multimeter only in normal temperature

environments, Temperature extremes Can shorten the life of

electronic devices, damage the batteries, and distort or melt

3). Handle the multimeter gently and carefully. Dropping it can

damage the circuit boards and case and can cause fthe

multimeter to work improperly although the holster can provide

4). Keep the multimeter away from dust and dirt, which can

cause premature wear of ports.

5). Wipe the multimeter with a damp cloth occasionally to keep it

looking new. Do not use harsh Chemicals, cleaning solvents, or

strong detergents to clean the multimeter.

6). Use only fresh batteries of the required size and type .always

remove old or weak batteries. They Can leak chemicals that

destroy electronic circuits.

9-volt battery replacement

a) Ensure the instrument is not connected to any external

circuit. snap fastener “OFF” Position and remove the test leads

b) Remove the screw on the bottom case and lift the battery

case. Remove the spent battery and Replace it with a battery of

c) Please take out the battery when not using for a

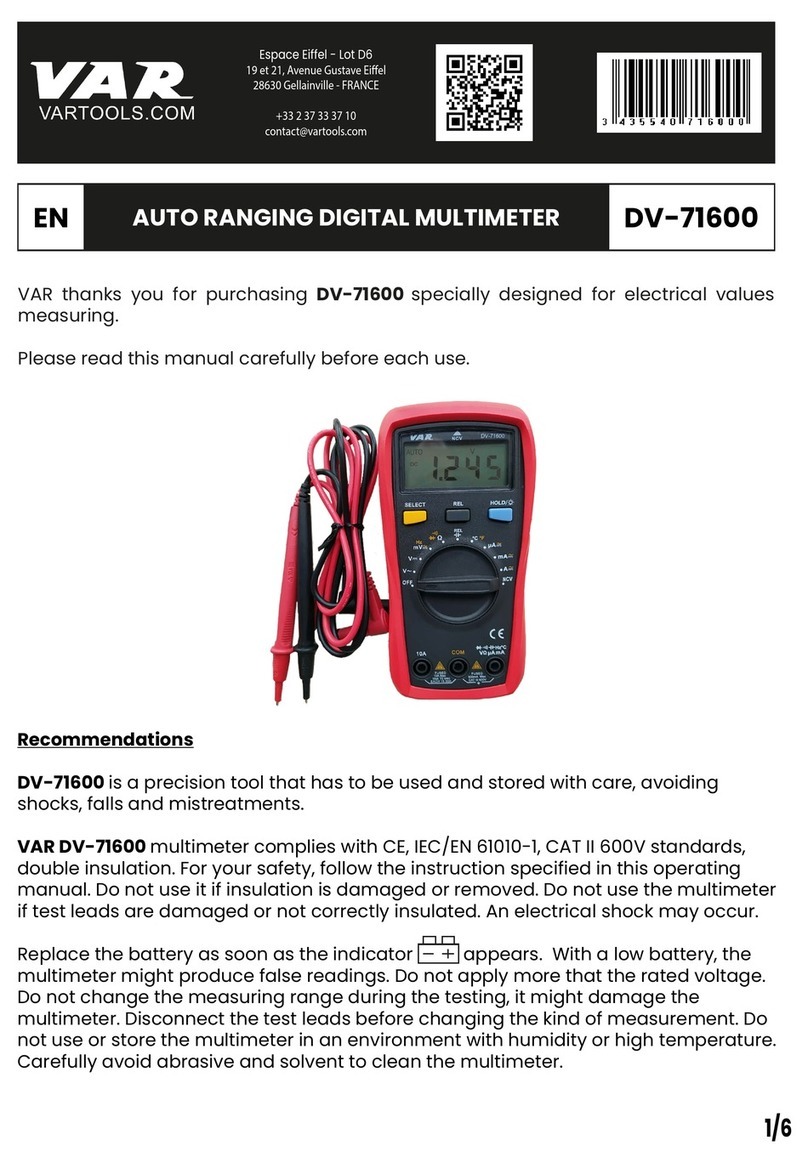

Above picture and content just for your reference.

Please be subject to the actual products if anything

different or updated. Please pardon for not