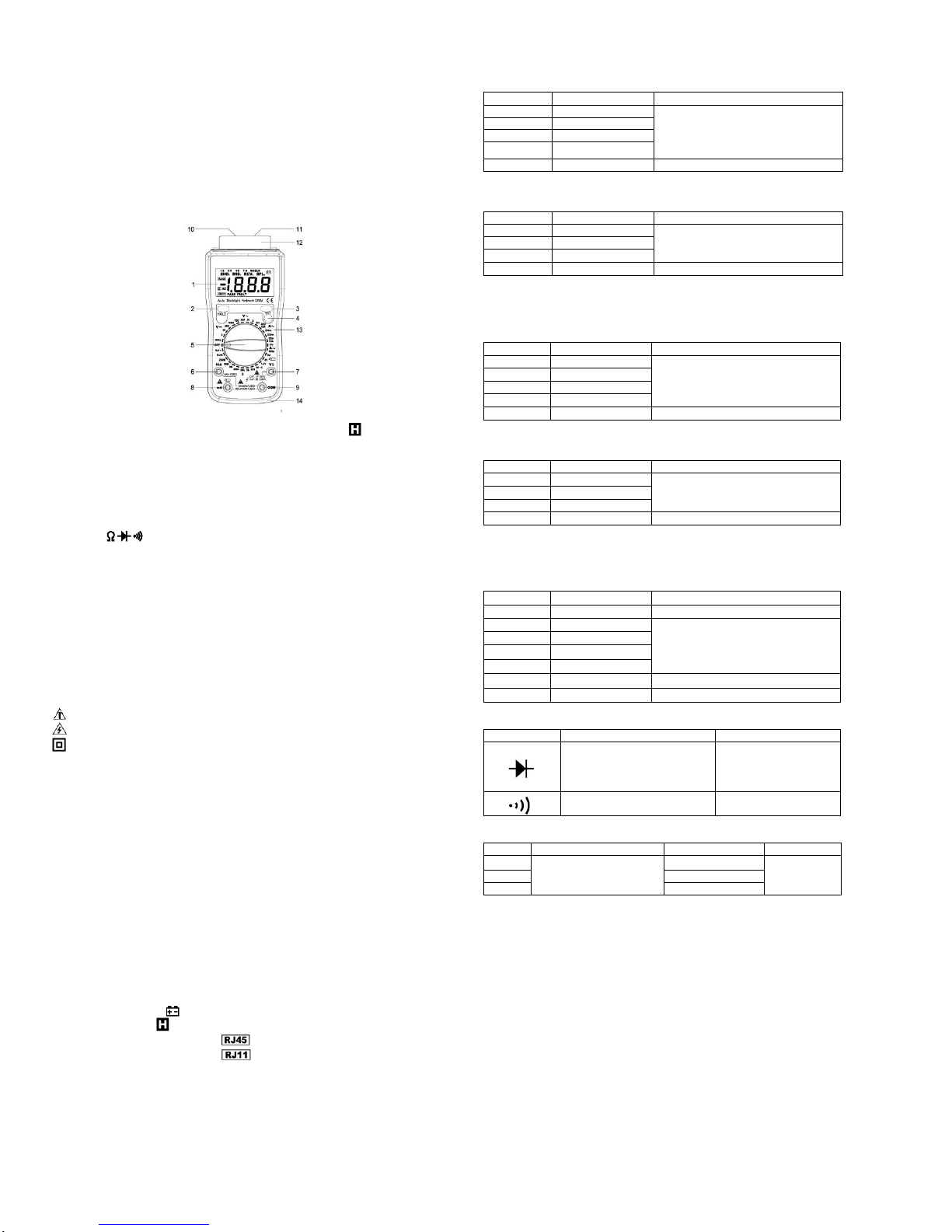

7-1 Attention before operation

7-1-1 Check battery. When the battery voltage drop below proper operation range, the “ ” symbol

will appear on the LCD display and the battery need to changed.

7-1-2 Pay attention to the “ ” besides the input jack which shows that the input voltage or current

should be within the specified value.

7-1-3 The range switch should be positioned to desired range for measurement before operation.

7-2 Measuring DC Voltage

7-2-1 Set the rotary switch at the desired “V” range position.

7-2-2 Connect the black test lead to COM jack and the red to VΩjack.

7-2-3 Connect test leads across the source or load under measurement.

7-2-4 You can get reading from LCD. The polarity of the red lead connection will be indicated along

with the DC voltage value.

NOTE:

1. When the value scale to be measured is unknown beforehand, set the range selector at the highest position.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher rangehas to be selected.

3. “ ” means you can’t input the voltage more than 1000V, it’s possible to show higher voltage, but it

may destroy the inner circuit or pose a shock.

4. Be cautious against shock when measuring high Voltage.

7-3 Measuring AC Voltage

7-3-1 Set the rotary switch at the desired “V” range position.

7-3-2 Connect the black test lead to COM jack and the red to VΩjack.

7-3-3 Connect test leads across the source or load under measurement.

7-3-4 You can get reading from LCD.

NOTE:

1. When the value scale to be measured is unknown beforehand, set the range selector atthe highestposition.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher rangehas to be selected.

3. “ ” means you can’t input the voltage more than 750V, it’s possible to show higher voltage, but it

may destroy the inner circuit or pose a shock.

4. Be cautious against shock when measuring high Voltage.

7-4 Measuring DC Current

7-4-1 Set the rotary switch at the desired “A”range position.

7-4-2 Connect the black test lead to COM jack and the red to the mA jack for a maximum 200mA

current , for a 200mA to 10A current, move the red lead to the 10A jack.

7-4-3 Connect test leads in series with the load under measurement.

7-4-4 You can get reading from LCD. The polarity of the red lead connection will be indicated along

with the DC current value.

NOTE:

1. When the value scale to be measured is unknown beforehand, set the range selector at the highest

position.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher range has

to be selected.

3. “ ” means the socket mA’s maximum current is 200mA and 10A’s maximum current is 10A, over

200mA or 10A current can be protected by the fast fuse.

4. On the 10A range, the measuring time should be less than 10 seconds to prevent precision from

affecting by circuit heating.

7-5 Measuring AC Current

7-5-1 Set the rotary switch at the desired “A”range position.

7-5-2 Connect the black test lead to COMjack and the red to the mA jack for a maximum 200mA

current , for a 200mA to 10A current, move the red lead to the 10A jack.

7-5-3 Connect test leads in series with the load under measurement.

7-5-4 You can get reading from LCD.

NOTE:

1. When the value scale to be measured is unknown beforehand, set the range selector at the highest

position.

2. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher range has

to be selected.

3. “ ” means the socket mA’s maximum current is 200mA and 10A’s maximum current is 10A, over

200mA or 10A current can be protected by the fast fuse.

4. On the 10A range, the measuring time should be less than 10 seconds to prevent precision from

affecting by circuit heating.

7-6 Measuring Resistance

7-6-1 Set the rotary switch at the desired “Ω” range position.

7-6-2 Connect the black test lead to COM jack and the red to VΩjack.

7-6-3 Connect test leads across the resistance under measurement.

7-6-4 You can get reading from LCD.

NOTE: Max. input overload: 500V rms<10sec

1. When only the figure “1” or “-1” is displayed, it indicates over-range situation and the higher range

has to be selected.

2. For measuring resistance above 10MΩ, the mete may take a few seconds to get stable reading.

3. When the input is not connected, i.e. at open circuit, the figure “1” or “-1” will be displayed for the

over-range condition.

4. When checking in-circuit resistance, be sure the circuit under test has all power removed and that

all capacitors have been discharged fully.

7-7 Diode & Audible continuity Testing

7-8-1 Set the rotary switch at the “ ” range position.

7-8-2 Connect the black test lead to COM jack and the red to VΩjack.

7-8-3 On diode range, connect the test leads across the diode under measurement, display shows

the approx. forward voltage of this diode.

7-8-4 On Audible continuity range, connect the test leads to two point

of circuit, if the resistance is lower than approx. 50Ω, the buzzer sounds.

NOTE: Make sure the power is cut off and all capacitors need to be discharged under this

measurement.

7-8 Battery Testing

7-8-1 Set the rotary switch at the desired “ ” range position.

7-8-2 Connect the black test lead to COM jack and the red to mA jack.

7-8-3 Connect test leads across the source or load under measurement.

7-8-4 You can get reading from LCD.

7-9 Telephone Line (RJ11) Testing

7-9-1 Open the cover of the network test on the top of the instrument by a screwdriver, take out the

test cover, and keep the screw well as we need the screw on after finish checking.

7-9-2 Set the rotary switch at the “ ” range position, the “” symbol will display on the LCD

screen.

7-9-3 Connect the telephone line with the test hole (RJ11) on the top of the instrument and make sure

it is good connection.

7-9-4 Connect the other side of the telephone line with SPC telephone exchange.

7-9-5 Press “TEST” key, if shows “PASS”, then the telephone line working normally, if shows “FAULT”,

the telephone line is abnormal.

7-10 Network Cable (RJ45) Testing

Warning:Please do not use this function in the condition of alive circuit, or it will damage the

instrument.

Network cable testing function is suitable for network cable which is T168A, T568B, 10Base-T and

Token Ring. It can find out the error cables and show on the cables symbol and their problem. If few

cables have error, all the error and cables symbol will display on the screen first, and press “TEST”

key one by one, cables symbol and its error detail will show on the screen one by one. You should

eliminate the error connections one by one until all the cable connection is correct.

Open Circuit: There is no indicating symbol for open circuit in this instrument. Normally there is 2~4

pair of twisted pair on a typical network, the symbol of cable which is open circuit will not display on

the screen, user should identify which symbol should be or should not be displayed on the screen

according to the true situation. If the cables symbol should be display but it did not, then means this

cables are open Circuit.

Short Circuit: There is short connection among cables (Figure 1).

Miswire: One side of two cables are wrong (Figure 2).

Reversed: One side of cable is reverse (Figure 3).

Split pairs: As wrong operation, a line of cable twine to other cable line while pressing the line

(Figure 4).

7-10-1 Open the cover of the network test on the top of the instrument by a screwdriver, take out the

test cover, and keep the screw well as we need the screw on after finish checking.

7-10-2 Set the rotary switch at the “ ” range position, the “” symbol will display on the

LCD screen.

7-10-3 Connect the network cable with the test hole (RJ45) on the top of the instrument and make

sure it is good connection.

7-10-4 Connect the other side of the network cable with network cable remote.

7-10-5 Press “TEST” key. For example: a network cable error conditions as follows: 1-2、3-6 are short

circuit, “1-2”、“3-6”、“4-5”、“7-8”、“SHIELD” and “SHO.” will display on the screen.

7-10-6 Press “TEST” key again, “1-2”、“3-6” and “SHO.”will display on the screen, keep press “TEST”

key, the result of next pair of cable will display on the screen.

8. Battery replacement

8-1 When the battery voltage drop below proper operation range the " " symbol will appear on the

LCD display and the battery need to changed.

8-2 Before changing the battery, power off the meter and remove the test leads from the terminals.

Open the cover of the battery cabinet by a screwdriver.

8-3 Replace the old battery with the same type battery (9V 6F22 or NEDA 1604).

8-4 Close the cover of the battery cabinet and fasten the screw.

9. Fuse replacement

9-1 This meter is provided with a 200mA/500V fast fuse to protect the battery test and the current

measuring circuits which measure up to 200mA, with a 10A/500V fuse to protect the 10A range.

9-2 Ensure the meter is not connected to any external circuit, power off the meter and remove the test

leads from the terminals. Open the bottom case by a screwdriver.

9-3 Replace the old fuse with the same type and rating: 6×30mm 200mA/500V fast fuse or 6×30mm

10A/500V fast fuse.

9-4 Close the bottom case and fasten the screw.

10. Maintenance

10-1 Before attempting to remove the battery door or open the case, be sure that test leads have been

disconnected from measurement circuit top avoid electric shock hazard.

10-2 You must replace the test leads if the lead is exposed, and should adopt the leads with the same

specifications as origin.

10-3 Use only moist fabric or small amount of detergent but not chemical solution for cleaning.

10-4 Do not use the meter before the back cover is properly closed and screw secured. Upon any

abnormality, stop operation immediately and send the meter for maintenance.

10-5 Please take out the battery when not using for a long time.

11. Accessories

[1] Test Leads: electric rating 1000V 10A

[2] Operator’s Manual

[3] Network Cable Remote