HoldPeak HP-760E User manual

Other HoldPeak Multimeter manuals

HoldPeak

HoldPeak 860D User manual

HoldPeak

HoldPeak 760J Installation manual

HoldPeak

HoldPeak 4201 User manual

HoldPeak

HoldPeak 39K User manual

HoldPeak

HoldPeak 6688D User manual

HoldPeak

HoldPeak 770HD User manual

HoldPeak

HoldPeak 760A Installation manual

HoldPeak

HoldPeak HP-770H User manual

HoldPeak

HoldPeak 860N User manual

HoldPeak

HoldPeak 870N User manual

HoldPeak

HoldPeak HP-770H User manual

HoldPeak

HoldPeak 870CR User manual

HoldPeak

HoldPeak HP-36C User manual

HoldPeak

HoldPeak 90F User manual

HoldPeak

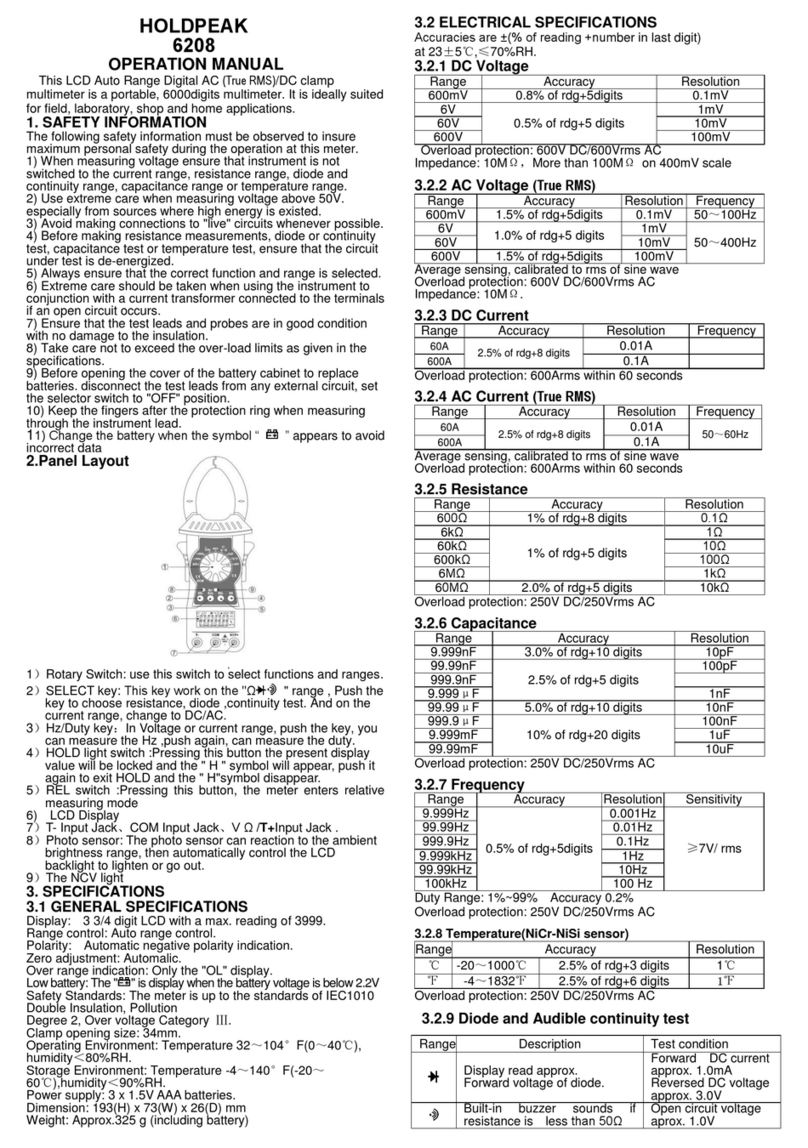

HoldPeak 6208 User manual

HoldPeak

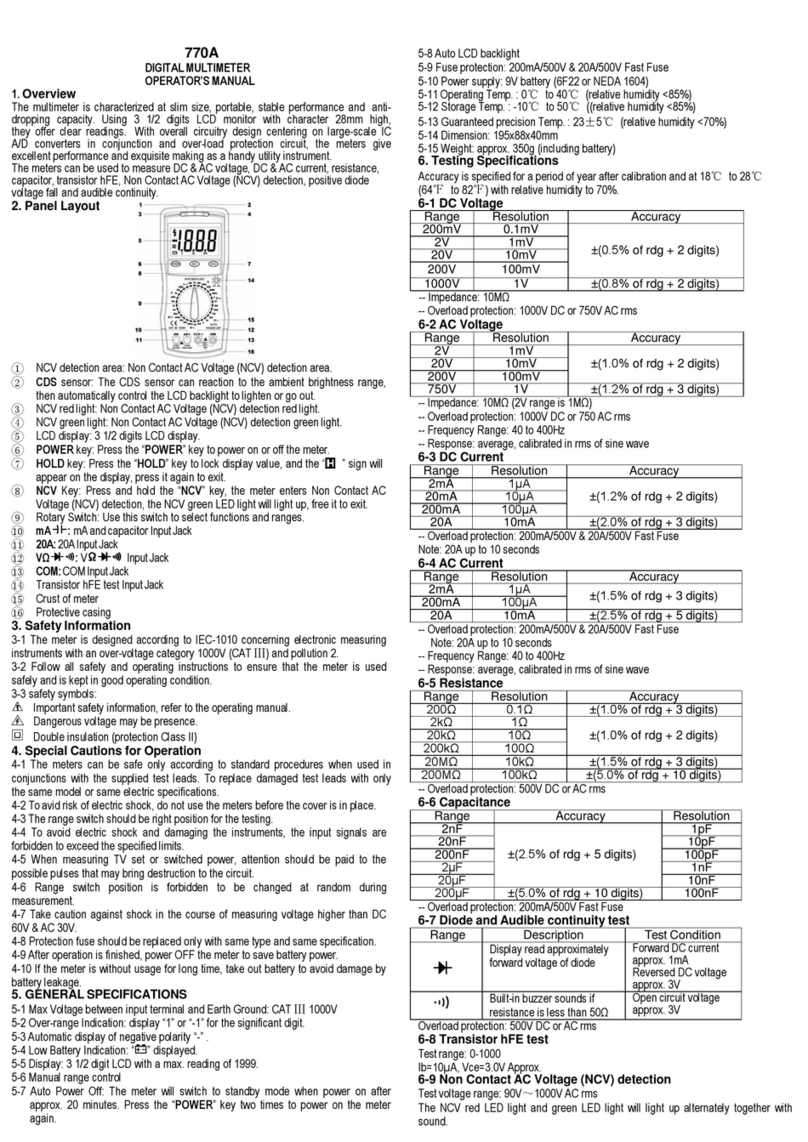

HoldPeak 770A User manual

HoldPeak

HoldPeak HP-37A User manual

HoldPeak

HoldPeak 6300 User manual

HoldPeak

HoldPeak 850E User manual

HoldPeak

HoldPeak 770D User manual