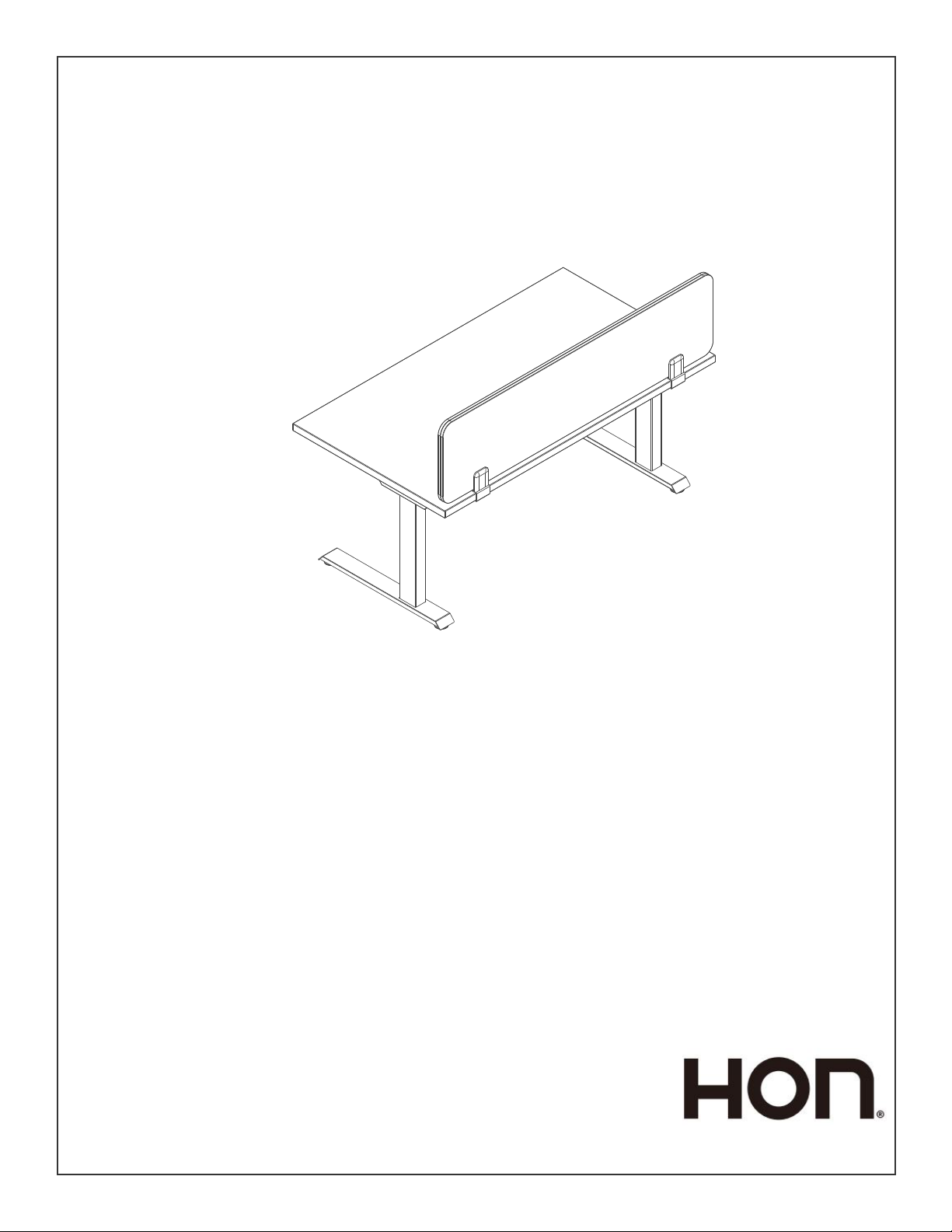

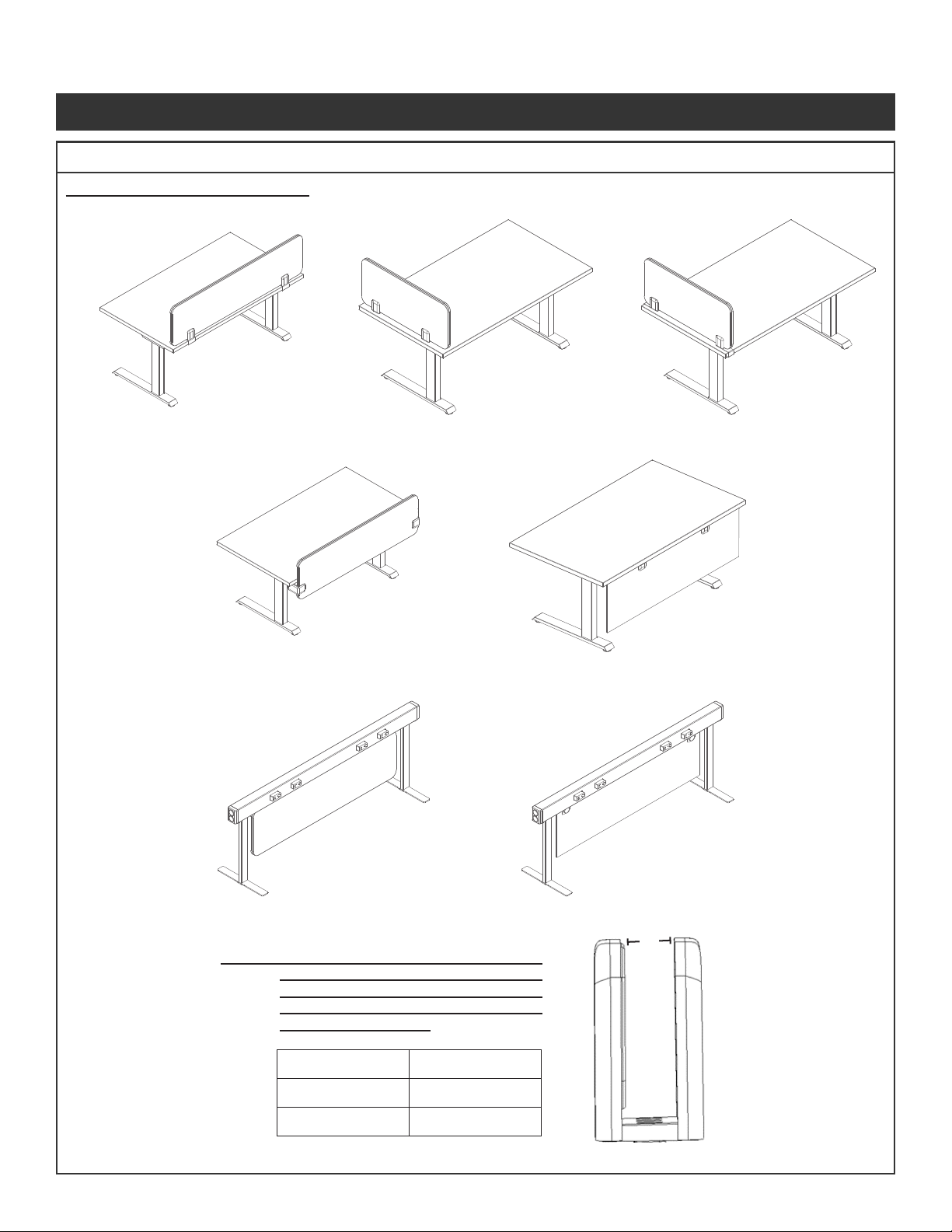

Universal Screens

Installation Instructions

Index

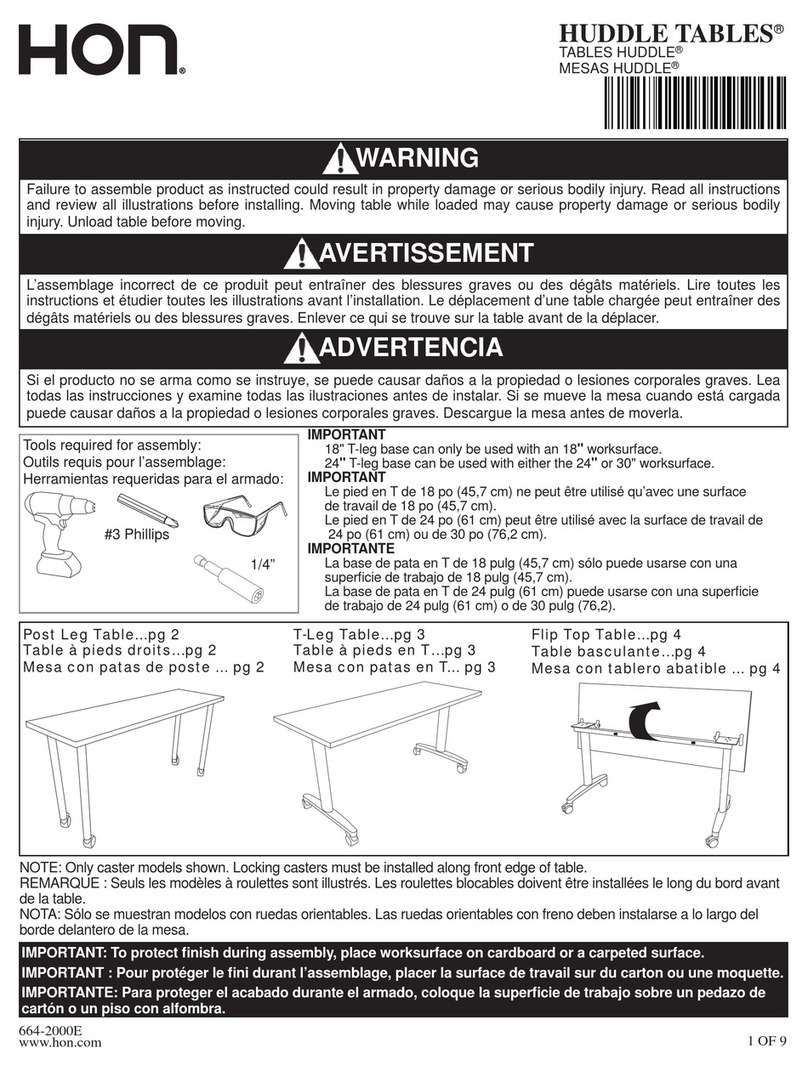

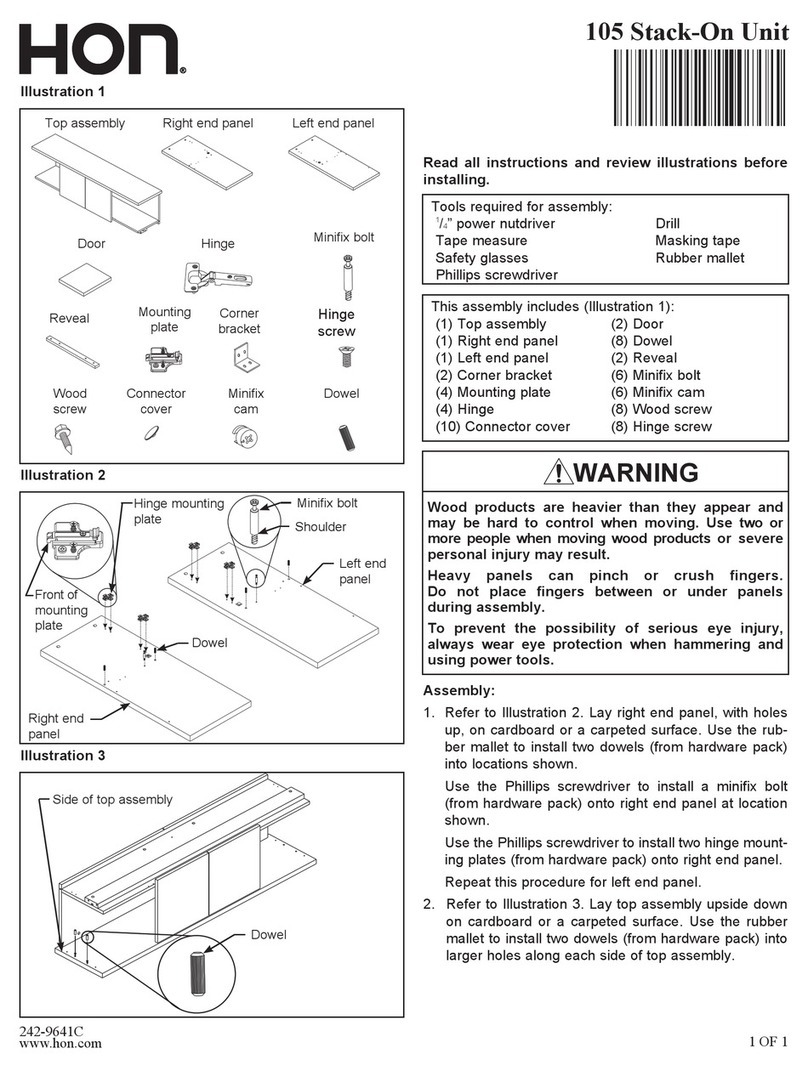

Screen Overview .................................. ............................2

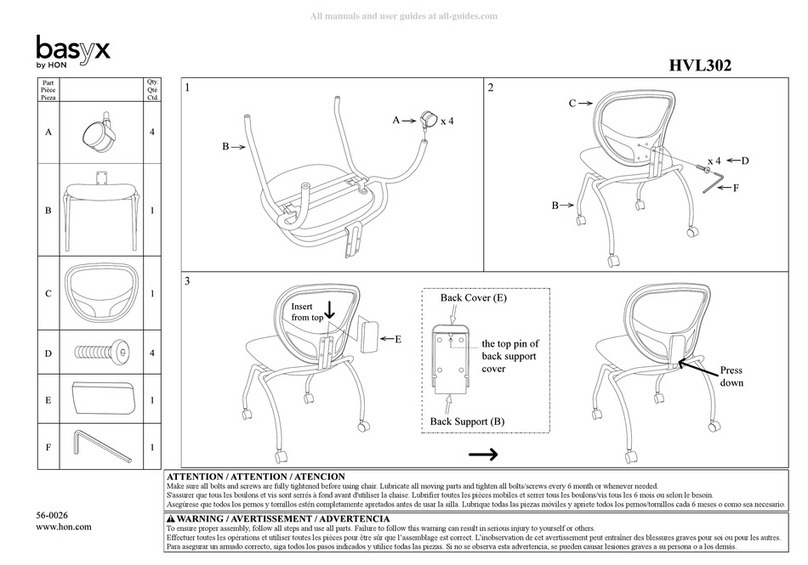

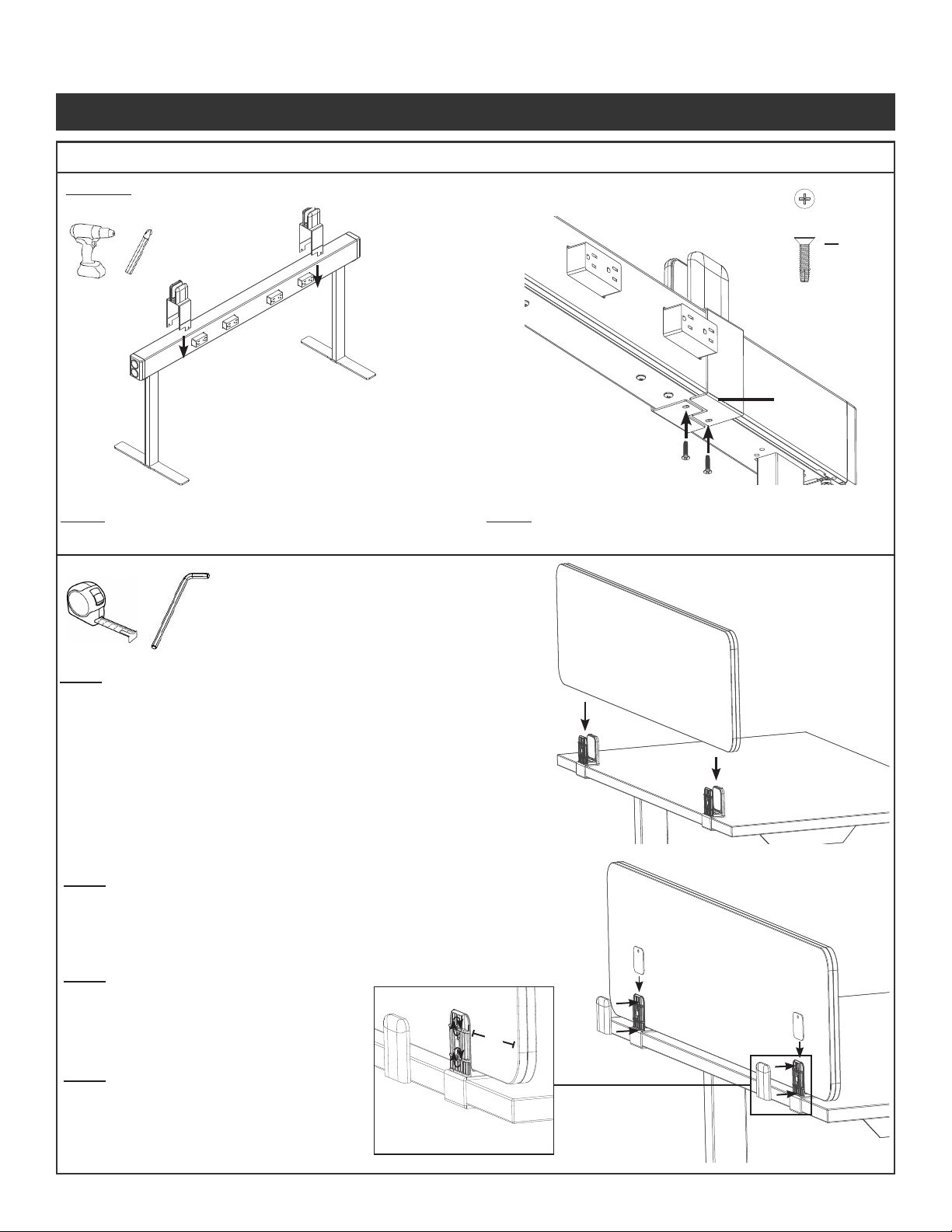

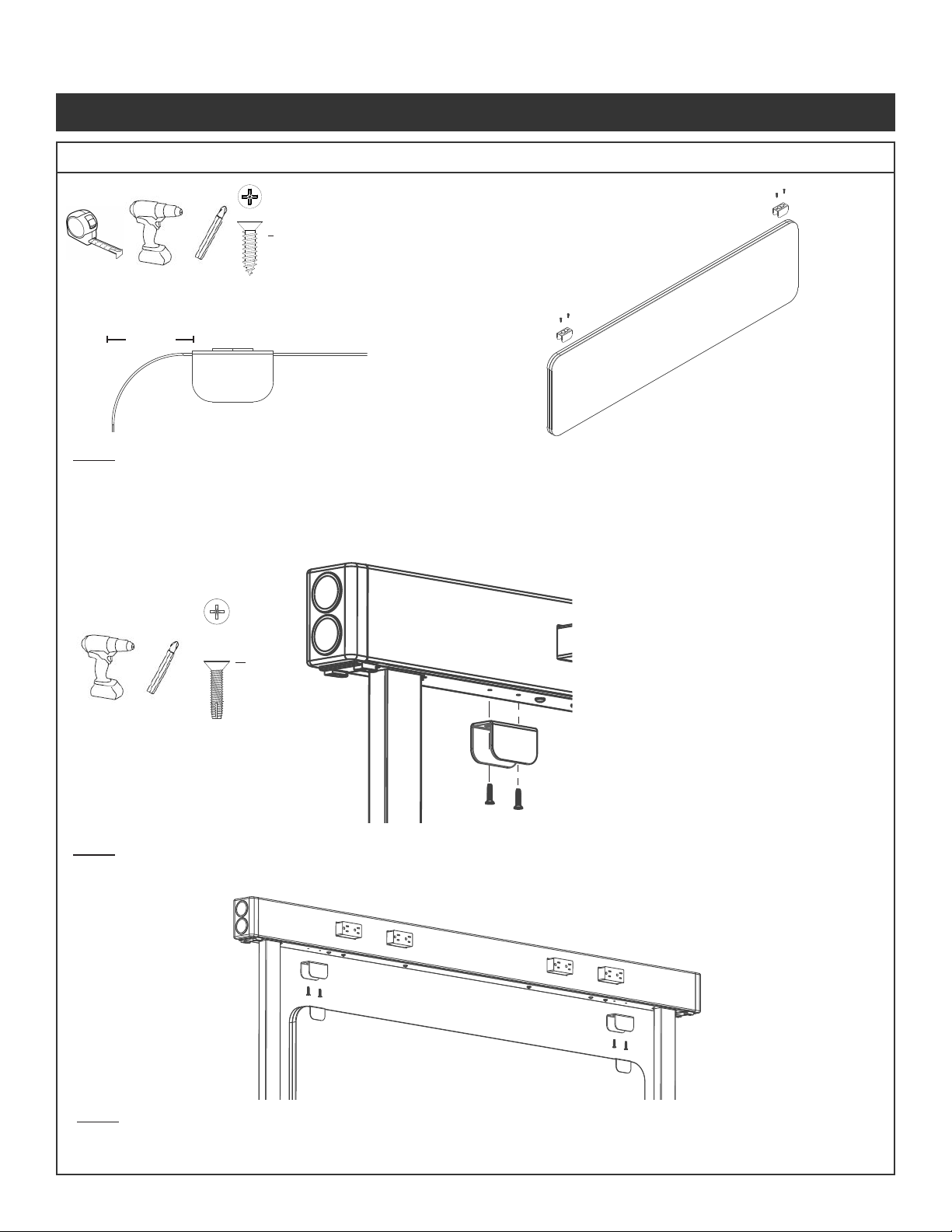

U - Bracket Installation ............................ ..........................3-6

1. Side Mount Lateral (HUSFSMB1 | HUSFSMB2)

2. Front to Back Lateral (HUSLATB1 | HUSLATB2)

3. Top Mount Lateral (HUSTOPB1 | HUSTOPB2)

4. Elevated (HUSUPMB1 | HUSUPMB2)

5. Sit on Surface (HUSSOSB1 | HUSSOSB2)

6. Empower (HUSEMPB1 | HUSEMPB2)

7. Gravitation (HUSGRVB1)

Above/Below Screens (HUSABMB1 | HUSLABF27## | HUSFABF#### | HUSAABF27##) .............7-8

Gravitation Modesty Screen - Fabric (HUSGRVB2) ..... ............................9

Gravitation Modesty Screen - Hard Surface (HUSGRVB3)..........................10

Gravitation Screen - PET (HUSGRVB5) ................. ...........................10

Modesty Screens (HUSFMOD13## | HUSLMOD13## | HUSMODB1) . ........................11-12

Alignment Clip Installation ........................ ...........................12

Hardware Chart ................................... ...........................13

Muscatine, Iowa 52761-0071

www.hon.com

Tools Needed:

1/8” Allen Wrench

Drill

Tape Measurer

#2 Phillips Driver

1/4” Hex Driver

Driver Extension

1430120100_A 07/2022