B1

A6

B6

B2

A7

B7

B3

A8

B8

B4

B9

B5

CAUTIONS & WARNINGS

Cables & Wiring

Electro-sensitive Devices (ESD)

Take suitable ESD precautions when removing or installing printed circuit boards

(PCBs). Failure to comply will shorten life of the equipment and may invalidate any

warranty.

This is CE Marked to show that is conforms to the requirements of the following

European Community Directives:

- The EMC Directive 2004/108/EEC, by the application of the following EMC standards:

EN61000-6-3:Electroniccompatibility(EMC)genericemissionstandardforResidential,

Commercial and light industrial environments.

EN50130-4: EMC Product family standard: Immunity requirements for components

of fire, intruder and social alarm systems.

- The Low Voltage Directive 2006/95/EE, by the application of the safety standard:

EN60950-1: Safety of information technology equipment.

- The Construction Products Directive 89/106/EEC, by the application of the following

standards:

EN54-2: Fire detection and fire alarm systems - control and indicating equipment.

EN54-4: Fire detection and fire alarm systems - power supply equipment.

WARNING: The PSU enclosure contains high voltage

circuitry. To avoid electric shock, do not remove the PSU

enclosure or allow the entry of conductive materials/fluids.

CAUTION: BATTERIES!

Risk of explosion if the battery is replaced by an incorrect type.

Take care when batteries are fitted.

It is normal for lead-acid type batteries to discharge hydrogen while being charged. The

panel enclosure is adequately ventilated to dissipate this hydrogen.

DO NOT seal the panel enclosure or mount the panel in a sealed enclosure or cavity.

WEEE Directive

This product contains electrical and electronic equipment that must be disposed of

suitably at the end of its service life. Contact your LocalAuthority to determine the

procedures for the disposal of waste electrical and electronic equipment.

Loop 1 (OUT)

Sounder Circuit 2

Digital Input Circuit 1

Digital Input Circuit 2 Network cable (IN)

Network cable (OUT)

Sounder Circuit 1

Loop 2 (OUT)

Loop 1 (IN)

Fire Relay output circuit

Fault Relay output circuit

Loop 2 (IN)

Repeater (RS485)

++

--

M3 Earth stud (x6)

Screen wires

AUX Output

997-659-000-2

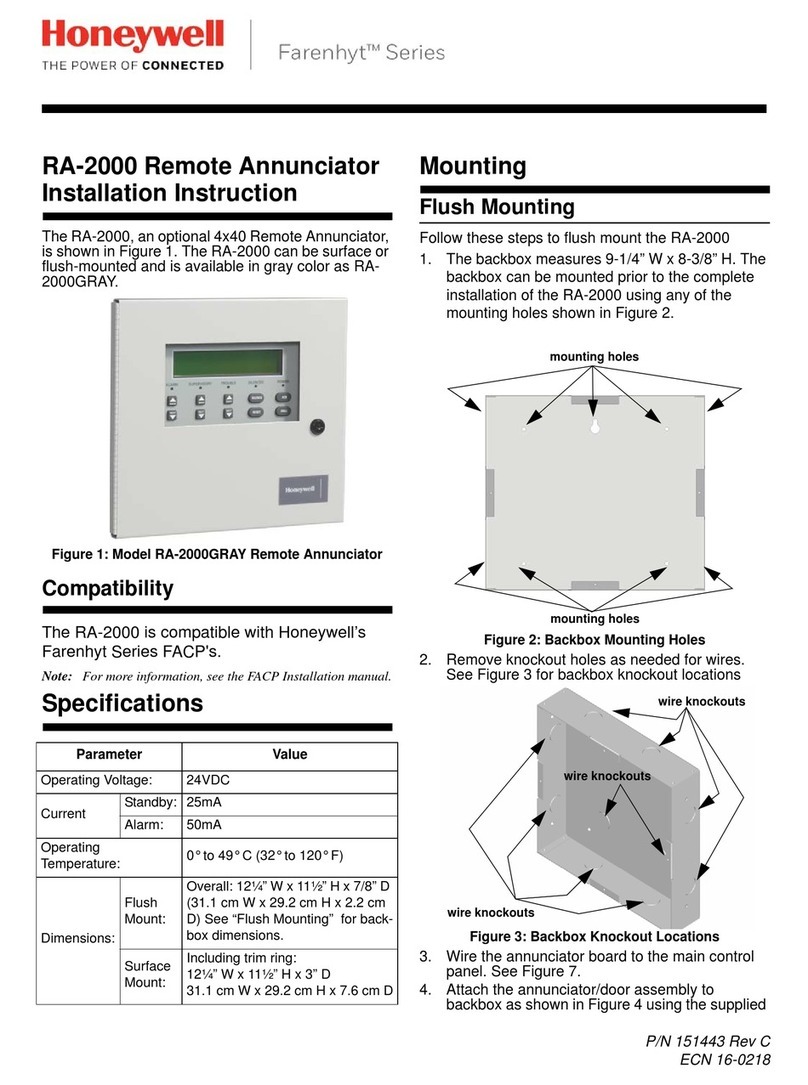

Pearl Panel - Basic Installation Guide

Dispose of batteries in accordance with local regulations.

This basic installation guide describes where to bring cabling and wiring in to the panel.

This information can be found in the Installation & Commissioning Manual in Section 5.3.1 Base PCB Wiring Connections. When bringing cables

through the wall-mounting plate, use the recommended cable entry apertures as illustrated below. This is a top view of the mounting plate. The

back row of apertures are shown as A1 to A8 and the front row are shown as B1 to B9. The recommended cable entry aperture for the primary

supply cable is indicated.

Checking For Damage

1Carefully remove the Pearl fire control panel from its packaging. Do not discard this packaging

until an inspection of the product has been completed (refer to step 4 below).

2Inspect the product for any damage that may have occurred in transit.

3If no damage is evident, proceed with installation.

4If product appears to have been damaged, do not proceed with installation. Return to supplier,

re-using same packaging wherever possible. Include written details of damage.

Wall Mounting

The Pearl fire control panel has been designed to simplify the installation process and reduce the risk

of product contamination prior to starting system commissioning. To this end, the panel electronics

need not be installed until required for the commissioning process. With reference to the instructions

overleaf (which also contains a wall-mounting template for drilling the required holes), screws (B -

see overleaf) are provided for securing the enclosure to the wall plate. Screws for the wall-mounting

plate are not provided.

Inspection & Testing

Inspection and Testing should conform to any national, regional or local standards applicable for the specific installation.

Before connecting any field wiring to the panel the following tests must first be carried out:

- Check the continuity of all cable runs (including screens).

- Check the isolation between all cores and between cores and screen / earth. Minimum isolation of 2Mohms is required.

- Check that the screen of all signal cables is not grounded to earth elsewhere in the building and that it is installed in accordance with recommendations –

refer to relevant wiring installation sections in the Installation & Commissioning Manual.

- Check that signal cables are not run in cable trays, or similar, alongside power cables for this and other equipment.

Having successfully carried out the above tests and once any faults found have been rectified the panel is ready for connection of external cables and

wiring. The recommended cable entry points for connection to the Base PCB are shown above. Connect the screen drain wires to the nearest earth stud

in the enclosure.

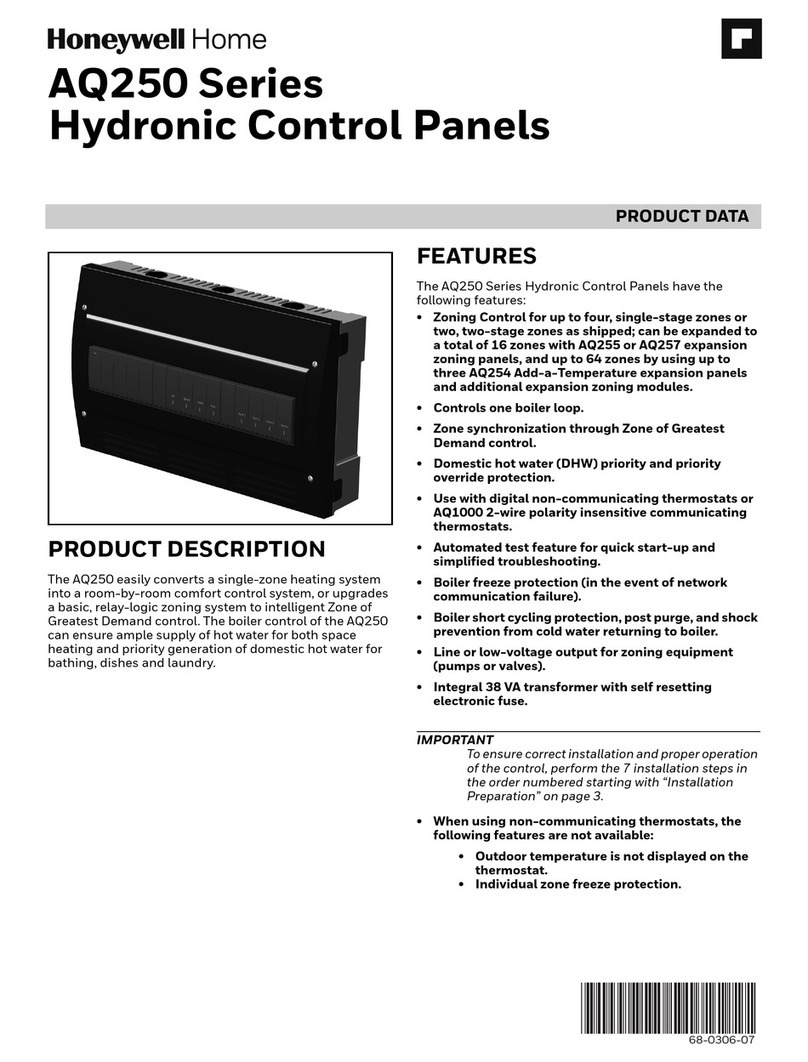

External Power Connection

The Pearl fire alarm control panel receives power from a 230V, 50Hz primary supply.

Open and lock out the main circuit breaker before connecting any wiring. DO NOT connect power until

panel is ready to perform commissioning tests.

The external primary supply cable must be brought in and terminated at the Mains Termination Block

(MTB) provided. Connect the Neutral (blue) wire to termination point ‘N’ and connect the Phase or Live

(brown) wire to termination point marked ‘L’. Terminate the primary earth wire to the stud located to the

lower-right of the MTB using the ring terminal, plain and spring washers and M4 nut provided. The

cable used for the primary supply must conform with the electrical wiring specifications of the country

and local requirements. MAKE SURE the supplied MTB safety cover (A) is fitted over the wiring

termination screw heads after the mains supply wiring termination has been made.

Primary supply cable gland and cord anchorage bushing used to route the primary supply cable through

the 20mm cable aperture MUST have a minimum flame retardant rating of UL94V0. Recommended

alternatives are given in the Installation & Commissioning Manual.

Battery Installation

The enclosure requires the installation of 12Ah batteries. Two are required. The standby batteries should be located in the enclosure as shown in the diagrams

overleaf.

Allow a sufficient air gap between them (10mm recommended) to allow for heat dissipation.

Primary Supply

Remove the door before installing the enclosure on the wall bracket.

Ensure adequate clearance is provided (> 200mm) to the left of the panel to allow unrestricted

access to the internal equipment with the door open.

A1 A2 A3 A4

A5

230Vac

L

N

FUSE: 1.6A (T) 250V HRC

NL

L

N

FUSE: 1.6A (T) 250V HRC

A