7 69-0814—1

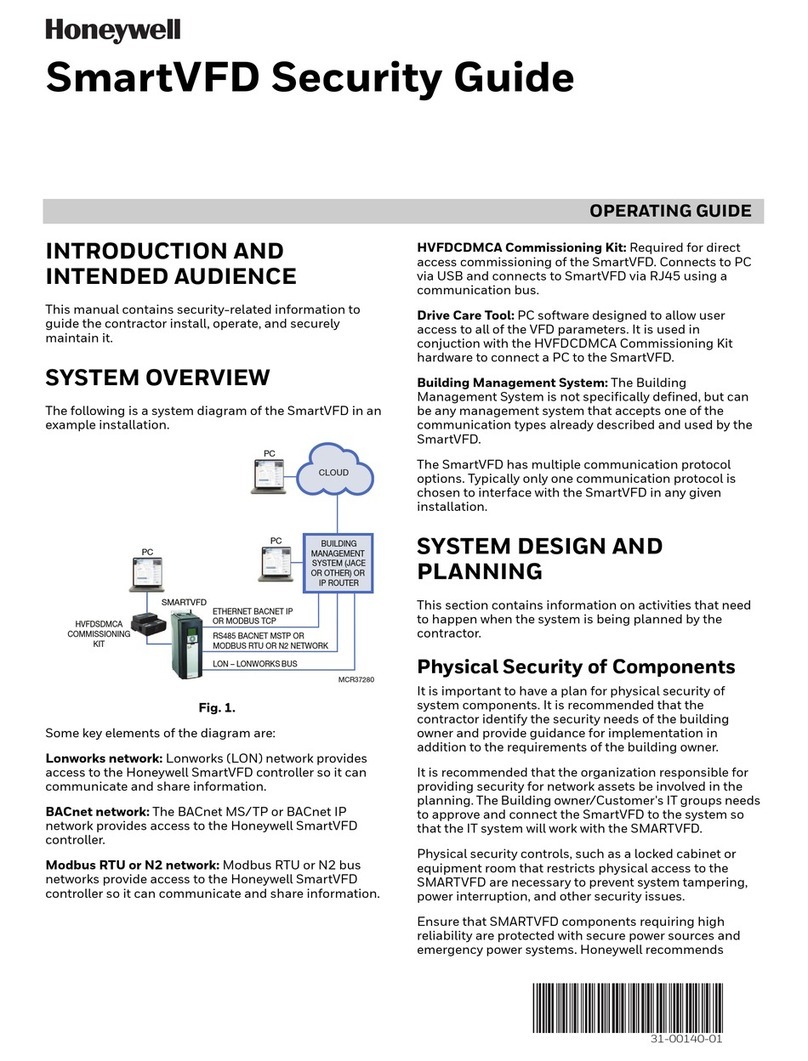

Step-Opening Pressure Regulator

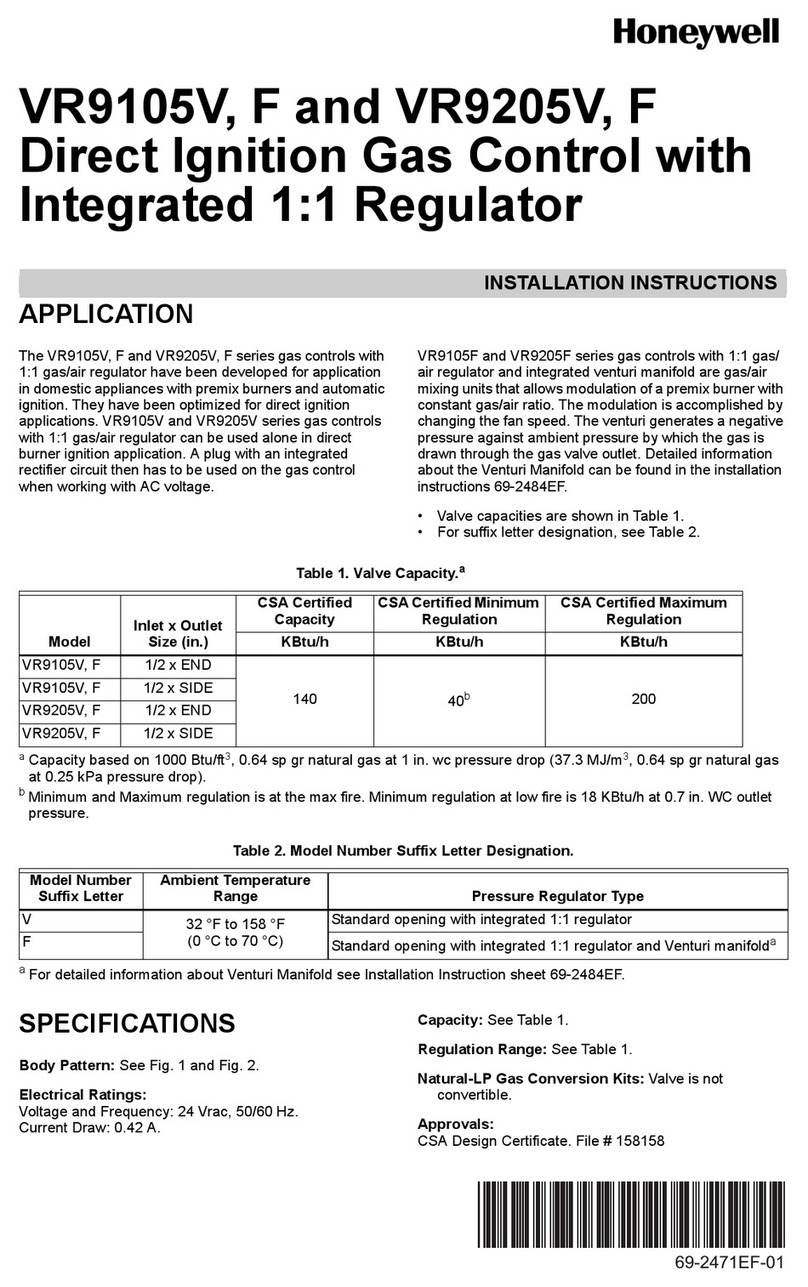

1. The gas control outlet pressure should match the

manifold pressure listed on the appliance nameplate.

2. With the main burner operating, check the gas con-

trol flow rate using the meter clocking method.

3. If desired flow rate is not as stamped on the control,

check the inlet pressure using a manometer at inlet pres-

sure tap or upstream of the gas control. Regulators are

fixed.Theyarenotadjustable. If the inlet pressure isinthe

normal range (refer to Table 3), replace the entire gas

control. Otherwise, take the necessary steps to provide

proper gas pressure to the gas control.

4. Carefully check main burner lightoff at the step pres-

sure. Make sure the main burner lights smoothly and

without flashback to the orifice and that all ports remain

lit. Cycle the main burner several times, allowing at least

30 seconds between cycles for the regulator to resume the

step function. Repeat after allowing main burner to cool.

CHECK SAFETY SHUTDOWN PERFORMANCE

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Performthe safety shutdown test any time work is

done on a gas system.

NOTE: Read steps 1 through 7 below before starting, and

compare to the safety shutdown or safety lockout tests

recommended for the intermittent pilot (IP) module.

Where they differ, use the procedure recommended for

the module.

1. Turn off knobs on entire gas control.

2. Set thermostat or controller above room temperature

to call for heat.

3. Watch for spark at pilot burner either immediately or

following prepurge. See IP Module specifications.

4. If module has timed ignition, time the length of the

spark operation. See IP Module specifications.

5. After the module locks out, open gas control knobs

and make sure there is no gas flow to the pilot or main

burner. With modules that continue spark until pilot lights

or system is shut down manually, pilot should light when

gas control knobs are opened.

6. Setthermostat below room temperatureand wait one

minute.

7. Operate system through one complete cycle to make

sure all controls operate properly.

Maintenance

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Do not disassemble the gas control or either

valve. They contain no replaceable components.

Attempted disassembly or repair can damage the

gas control.

Regularpreventivemaintenance isimportantinapplica-

tions such as commercial cooking, agricultural and indus-

trial operations that place a heavy load on system controls

because:

• In many such applications, particularly commercial

cooking, the equipment operates 100,000 to 200,000

cyclesper year . Such heavycycling can wear out the

gas control in one to two years.

• Exposure to water, dirt, chemicals and heat can dam-

agethe gas controlandshut down the controlsystem.

Themaintenanceprogramshouldincluderegularcheck-

out of the entire gas control; see Startup and Checkout

section. To check out the control system, see the appliance

manufacturer literature. Maintenance frequency must be

determined individually for each application. Some con-

siderations are:

•Cyclingfrequency.Appliancesthatmaycycle100,000

times annually should be checked monthly.

•Intermittent use. Appliances that are used seasonally

shouldbecheckedbeforeshutdownandagainbefore

the next use.

•Consequence of unexpected shutdown. Where the

cost of an unexpected shutdown would be high, the

system should be checked more often.

•Dusty, wet, or corrosive environment. Since these

environmentscancause the gas control to deteriorate

more rapidly, the system should be checked more

often.

If the gas controls will be exposed to high ammonia

conditions;e.g.,thoseusedingreenhousesoranimal barns,

contact your Honeywell sales representative to request a

gas control with corrosion resistant construction.

The entire gas control should be replaced if:

• It does not perform properly during checkout or

troubleshooting.

• The gas control knobs are hard to turn.

• The gas control is likely to have operated for more

than 200,000 cycles.

Service

WARNING

FIRE OR EXPLOSION HAZARD

CAN CAUSE PROPERTY DAMAGE,

SEVERE INJURY, OR DEATH.

Do not disassemble the gas control or either

valve. They contain no replaceable components.

Attempted disassembly or repair will damage the

gas control.

CAUTION

Do not apply a jumper across or short the valve

leadwires. Doing so can burn out the heat antici-

pator in the thermostat or damage the electronic

module.

IMPORTANT: Allow 60 seconds after shutdown before

re-energizing step-opening model to assure lightoff

at step pressure.

!

!

!

!