Honeywell V5852A Service manual

Other Honeywell Control Unit manuals

Honeywell

Honeywell VR4611VA1007 User manual

Honeywell

Honeywell V4043A User manual

Honeywell

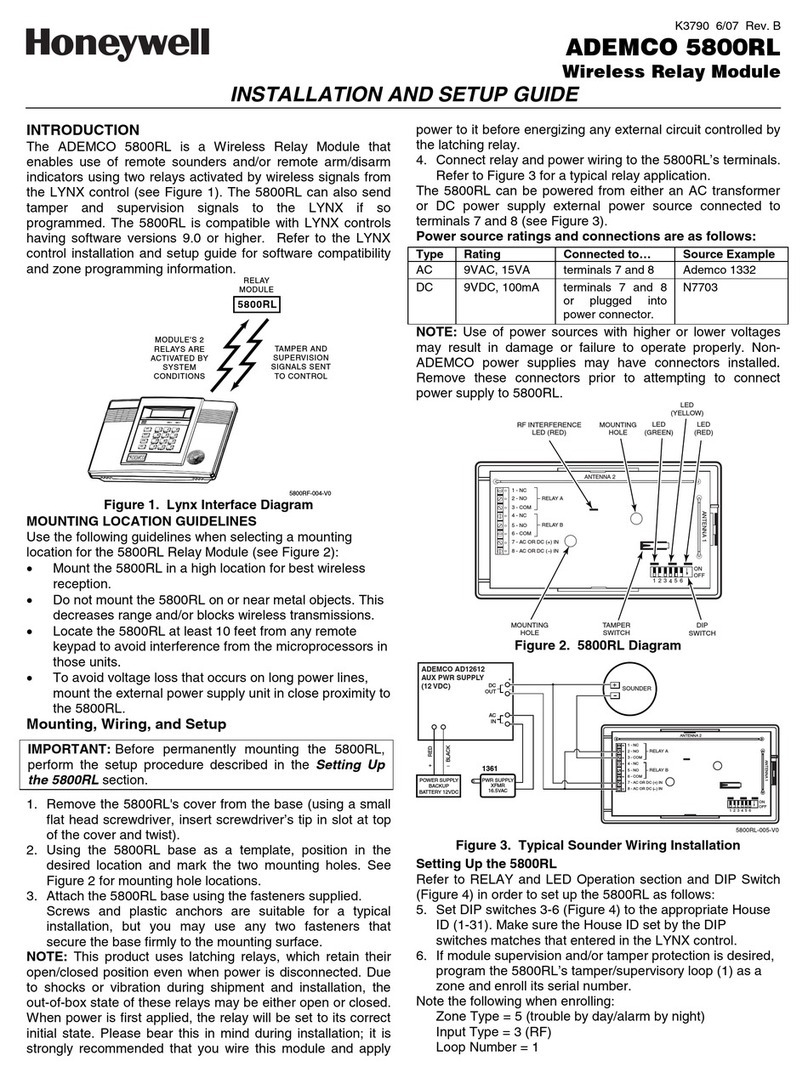

Honeywell ADEMCO 5800RL Assembly instructions

Honeywell

Honeywell Notifier NFG-8 User manual

Honeywell

Honeywell NetAXS-123 User manual

Honeywell

Honeywell XW100 User manual

Honeywell

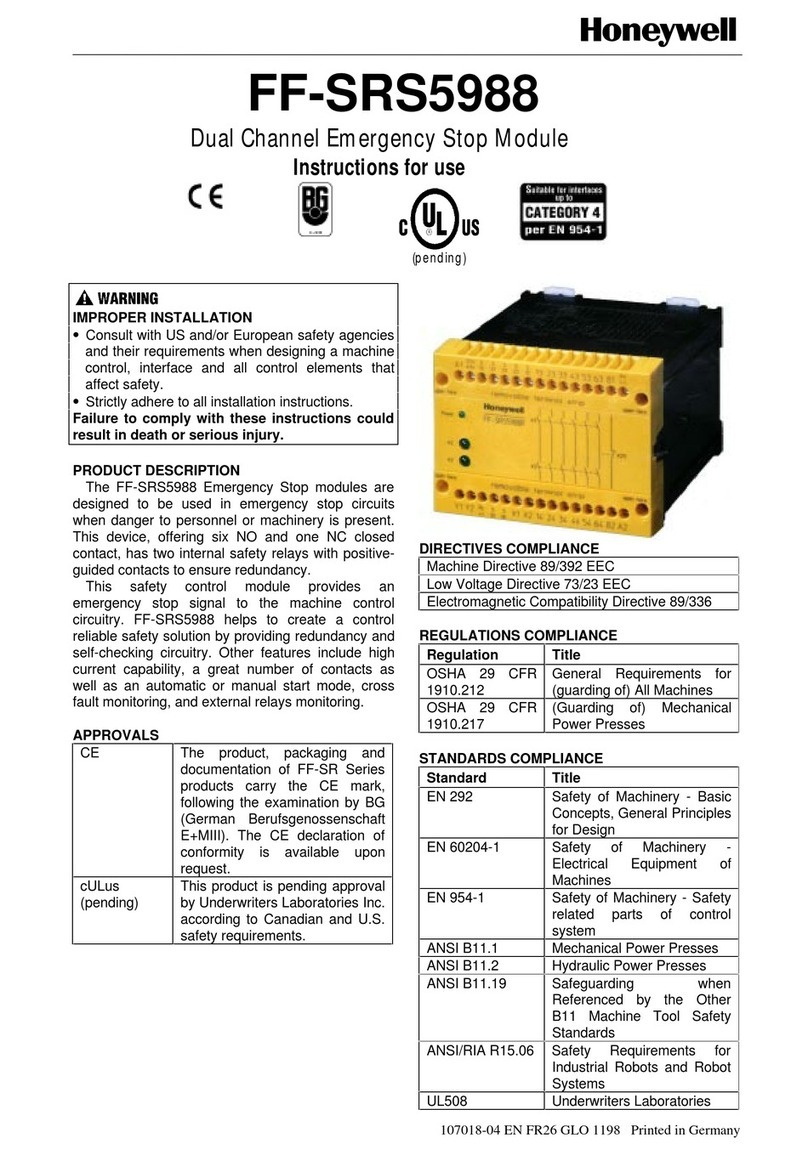

Honeywell FF-SRS5988 User manual

Honeywell

Honeywell FALCON MJ Pulse/M-Bus User manual

Honeywell

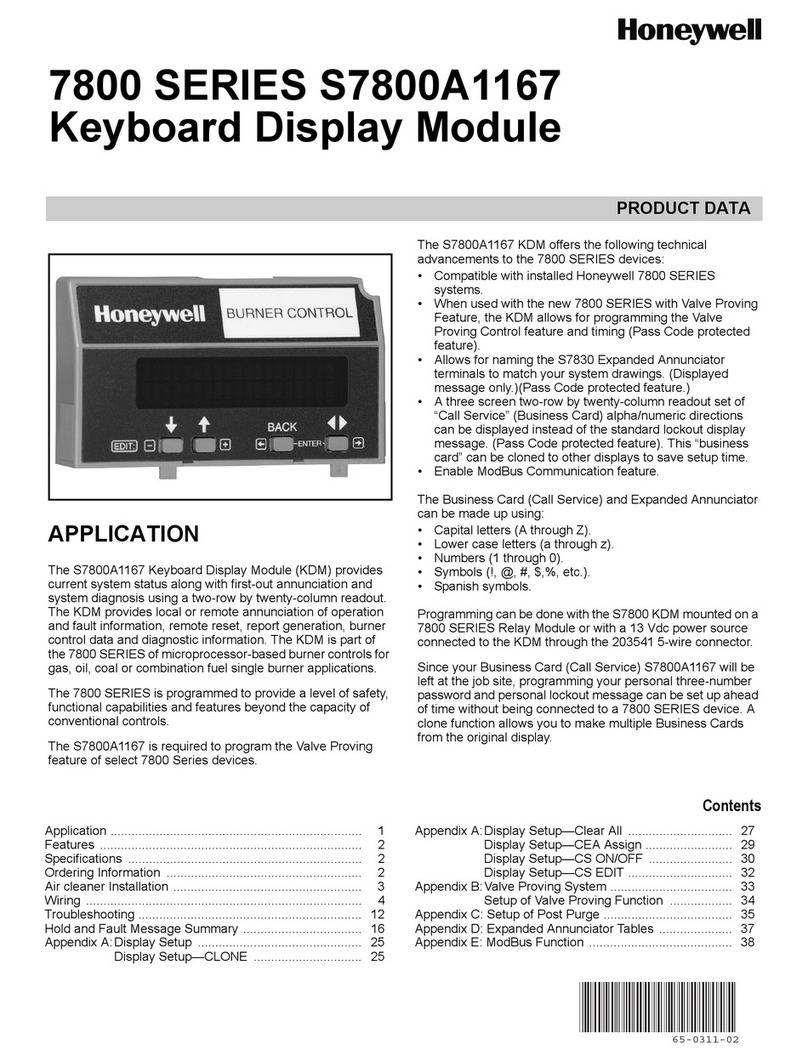

Honeywell S7800A1167 User manual

Honeywell

Honeywell RA890F Protectorelay Primary Control Installation guide

Honeywell

Honeywell MAXON 8730 Series User manual

Honeywell

Honeywell Elster Jeavons S200 User manual

Honeywell

Honeywell ModBus S7810M User manual

Honeywell

Honeywell SV2 Series User manual

Honeywell

Honeywell V5825B User manual

Honeywell

Honeywell BCU 460 Manual

Honeywell

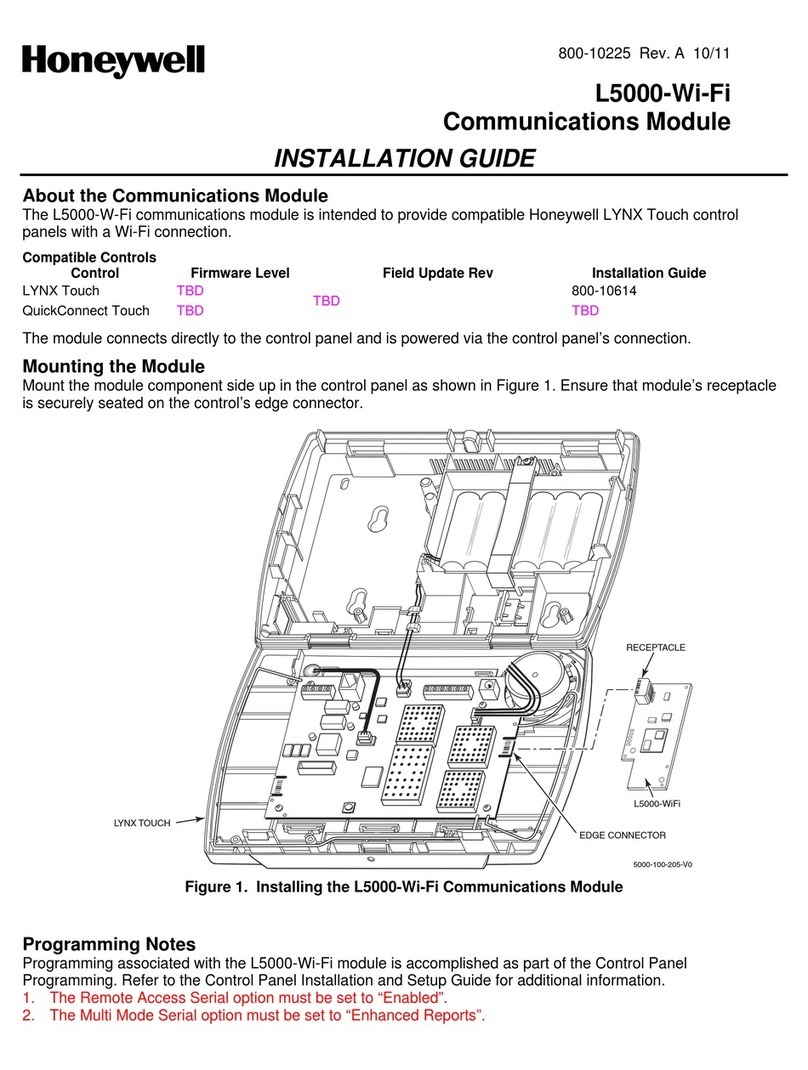

Honeywell L5000-Wi-Fi User manual

Honeywell

Honeywell NETAXS NX4L1 User manual

Honeywell

Honeywell LCBS Connect User manual

Honeywell

Honeywell Class 500 User manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual