S8600B,C,H,M;S8610B,C,H,M;S8670D,E,J,KINTERMITTENTPILOT GASIGNITIONCONTROL

บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

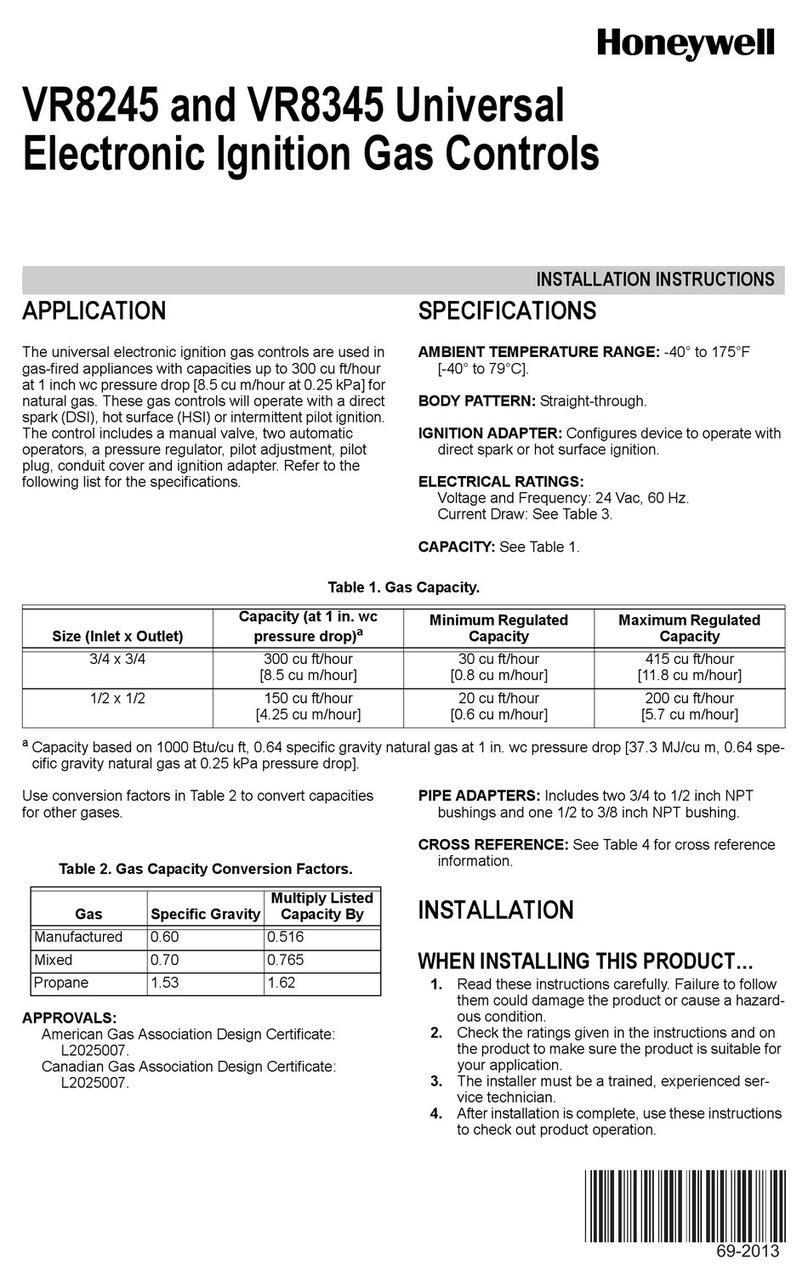

MAINVALVE

S8600 B,C; S8610 B,C; S8670 J,K

GND 24V

MV MV/PV PV (BRN) GND 24V

MAIN VALVE

STAGE 2

THERMOSTAT

AIRPROVINGSW ITCH

SENSE

SENSOR

3

Step 2: Verify control system ground.

Theigniter,flamesensor,andignitionmodulemustshare a common

ground with the main burner. Use thermoplastic insulated wire with

a minimum rating of 221°F (105°C)for thegroundwire;asbestos

insulationis not acceptable. If the temperature at the wire could

exceed 221°F (105°C), use a shield to protectthe wire

PILOT

1STOPERATOR

COM GROUND STAGE 1

2NDOPERATOR

R W2 W1

2

PILOT BU RNER/

from radiant heat generated by the burner. Connect the ground

wire as follows:

TWO STAGEDUAL VALVE

COMBINA TION GAS CONT ROL

4

LIMIT

CONTROLLER

COMBUS TION AIR BLOWER RELAY

IGNITER

PILOT GAS SUPPLY

a.

Fitoneendof the groundwirewithafemale1/4 in.

quick-connect terminal and connect it to the male

quick-connect GND (BURNER) terminal onthe ignition

module.

b.

Strip the other end ofthe wire and fasten it

1

L1L2 (HOT) L1 L2 COMBUSTION

(HOT) 1

AIRBLOWER

under the igniter bracket mounting screw. If nec- essary,

use a shield to protect the ground wire

1

POWER SUPPLY. PROVIDEDISCONNECT MEANSAND OVERLOAD PROTECTIONASREQUIRED.

2 ALTERNATE LIMIT CONTROLLER LOCATION.

3

MAXIMUM CABLE LENGTH 3 FT. [0.9 M].

4

CONTROLS IN 24VCIRCUIT MUST NOTBE IN GROUNDLEG TOTRANSFORMER.

from radiant heat.

c.

The burner serves as the common grounding area.If

thereisnotgoodmetal-to-metalcontact

Fig.8. S8600 B,C; S8610 B,C; S8670 J,K connections with

remote flame sensing in a heating system with a two-stage gas

control and power-assisted combustion.

CHECKOUT

Check out the gas control system:

•

Atinitialinstallationoftheappliance.

•

As part of regular maintenance procedures. Maintenance

intervals are determined by the application.See“Planning the

Installation” onpage2 formoreinformation.

•

Asthefirst stepintroubleshooting.

•

Any time work is done on thesystem.

WARNING

Fire or Explosion Hazard.

Failure to heed these warnings may cause fire or

explosion with property damage, injury, or loss of life.

1.

Ifyou smell gas or suspect a gas leak, turn off gas at

manual service valve and evacuate the building. Do

not try to light any appliance, do not touchany

electricalswitchortelephonein the building until you

are sure no spilled gas remains.

2.

Gas leak testmust be done as describedinthe steps

below on initial installation and any time workis done

involving the gas piping.

Step 1: Perform Visual Inspection.

a.

With power off,makesure allwiring connec- tions

arecleanandtight.

b.

Turnonpowertoapplianceandignitionmodule.

c.

Open manual shutoff valves in the gas line to the

appliance.

d.

Perform Gas Leak Testahead of gas control if piping

hasbeendisturbed.

GAS LEAK TEST (UPSTREAM OF GAS CONTROL)

Paint the gas control gasket edges and all pipe connections

upstream of the gas control with a rich soap and water

solution. Bubbles indicate gas leaks. Tighten the joints and

screws or replace component to stop gas leak. Recheck

with soap and water solution.

between the burner and ground, run a lead from the

burner to ground.

NOTE: Earth ground is not required.

Step 3: Review Normal Operating

Sequence and Module Specifications.

a. See “Operation” on page 8 and “Specifications” on page 2.

Step 4: Reset the Module.

a.

Turnthethermostattoitslowestsetting.

b.

Wait oneminute.

As you do the remaining steps, watch for points where operation

deviates from normal. Refer to the Troubleshooting guide on

page 15 to correct problems.

Step 5: Check Safety Shutoff Operation.

a.

Turngassupplyoff.

b.

Setthermostatorcontrollerabove roomtemper- ature to

callforheat.

c.

Watchforsparkatpilotburner eitherimmedi- atelyor

followingprepurge.Seedevicelabel.

d.

Timesparkfrom starttoshutoff.See device label.

e.

On all continuous retry models, wait 5 minutes. Ignition

sequence should start again followed by shutoff after 90

secondsmaximum.

f.

Openmanualgascockandmakesurenogasis flowing

topilotormainburner.

g.

Setthermostatbelowroomtemperatureand wait

oneminutebeforecontinuing.

Step 6: Check Normal Operation.

a.

Setthermostatorcontrollerabove roomtemper- ature to

callforheat.

b.

Makesurepilotlightssmoothlywhengas

reachesthepilotburner.

c.

Makesuremainburnerlightssmoothlywithout

flashback.

d.

Makesureburneroperatessmoothlywithout floating,

lifting, or flame rollout tothe furnace vestibule or heat

buildupinthevestibule.

e.

Perform agas leaktestintheappliance

.