Honeywell P906C Operation manual

Other Honeywell Controllers manuals

Honeywell

Honeywell ML7295E User manual

Honeywell

Honeywell Ultrakey Lite User manual

Honeywell

Honeywell Evohome Instructions for use

Honeywell

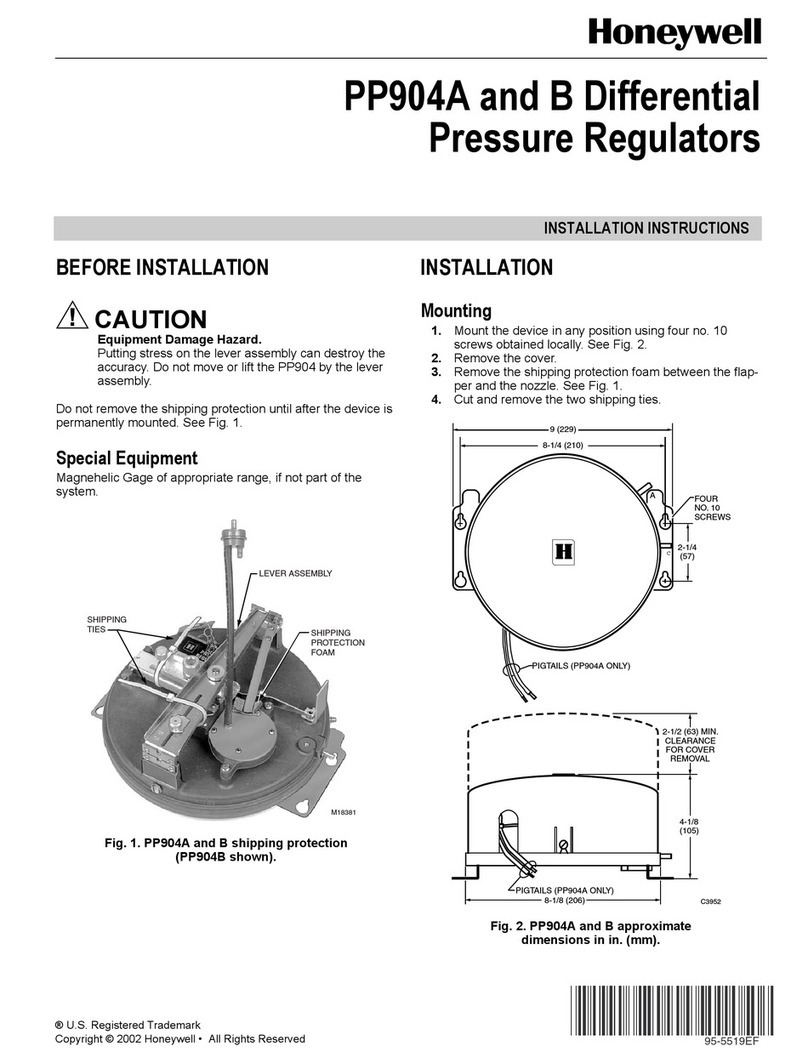

Honeywell PP904A User manual

Honeywell

Honeywell ATC928G3000 User manual

Honeywell

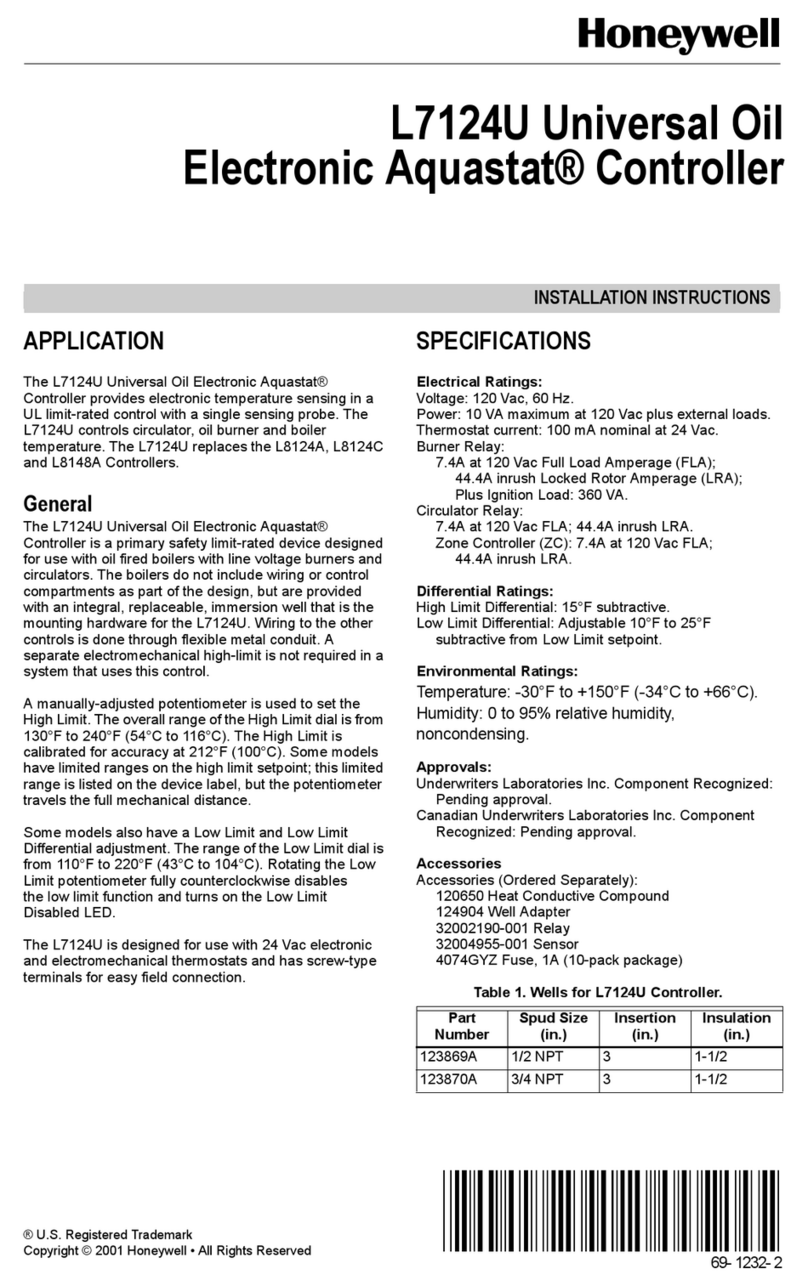

Honeywell L7124U User manual

Honeywell

Honeywell HVC0002 User manual

Honeywell

Honeywell CLMEVA00IB24NM User manual

Honeywell

Honeywell DCP552 Mark II User manual

Honeywell

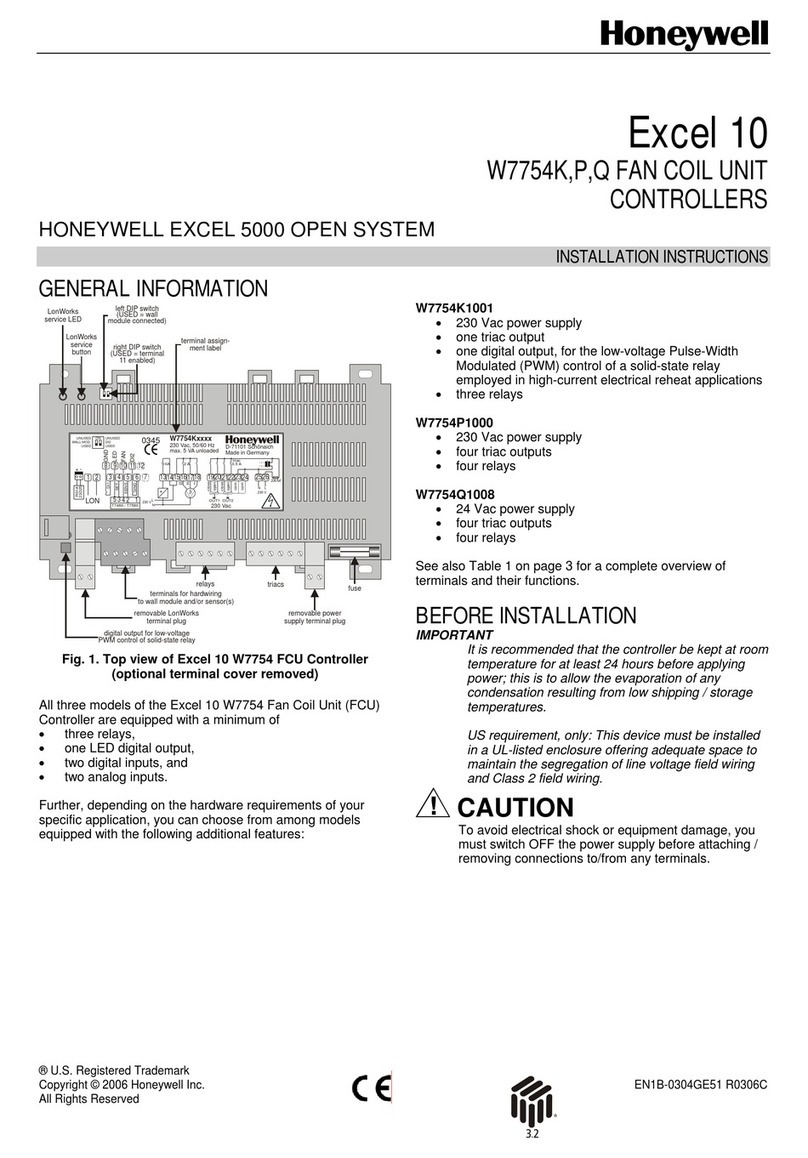

Honeywell Excel 10 User manual

Honeywell

Honeywell M7061 User manual

Honeywell

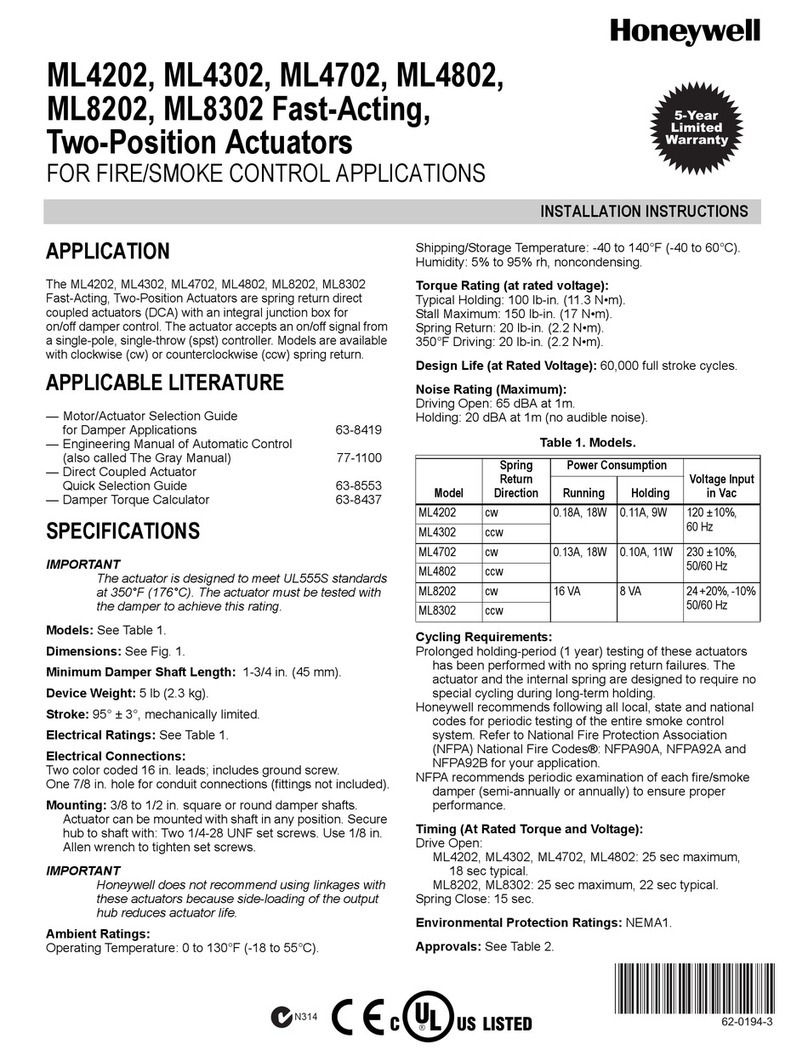

Honeywell FAST-ACTING, TWO-POSITION ACTUATORS ML4202 User manual

Honeywell

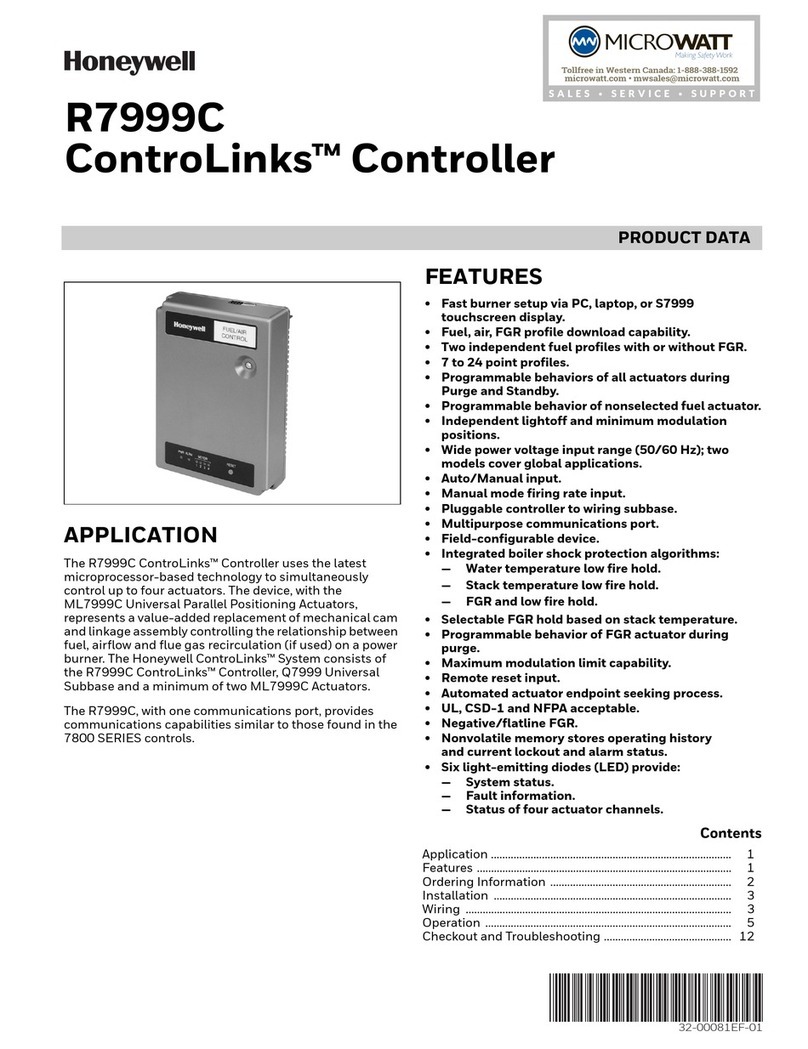

Honeywell ControLinks R7999C User manual

Honeywell

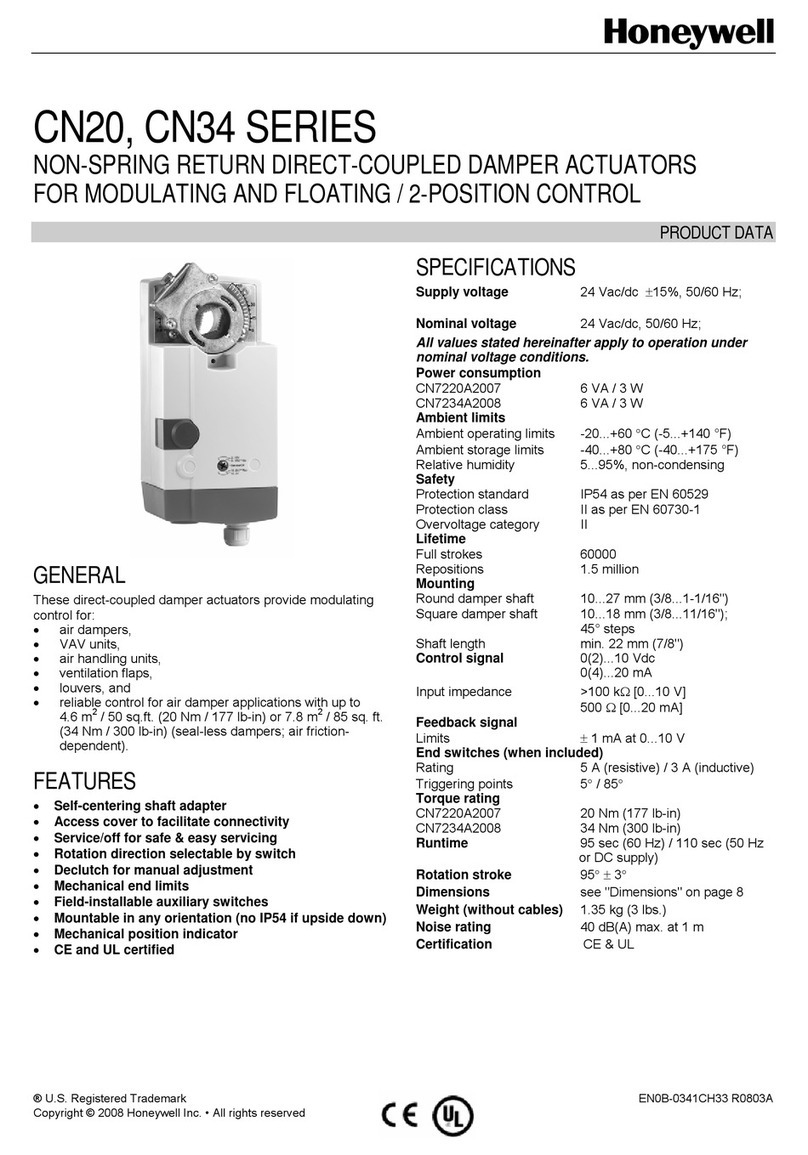

Honeywell CN34 Series Operation manual

Honeywell

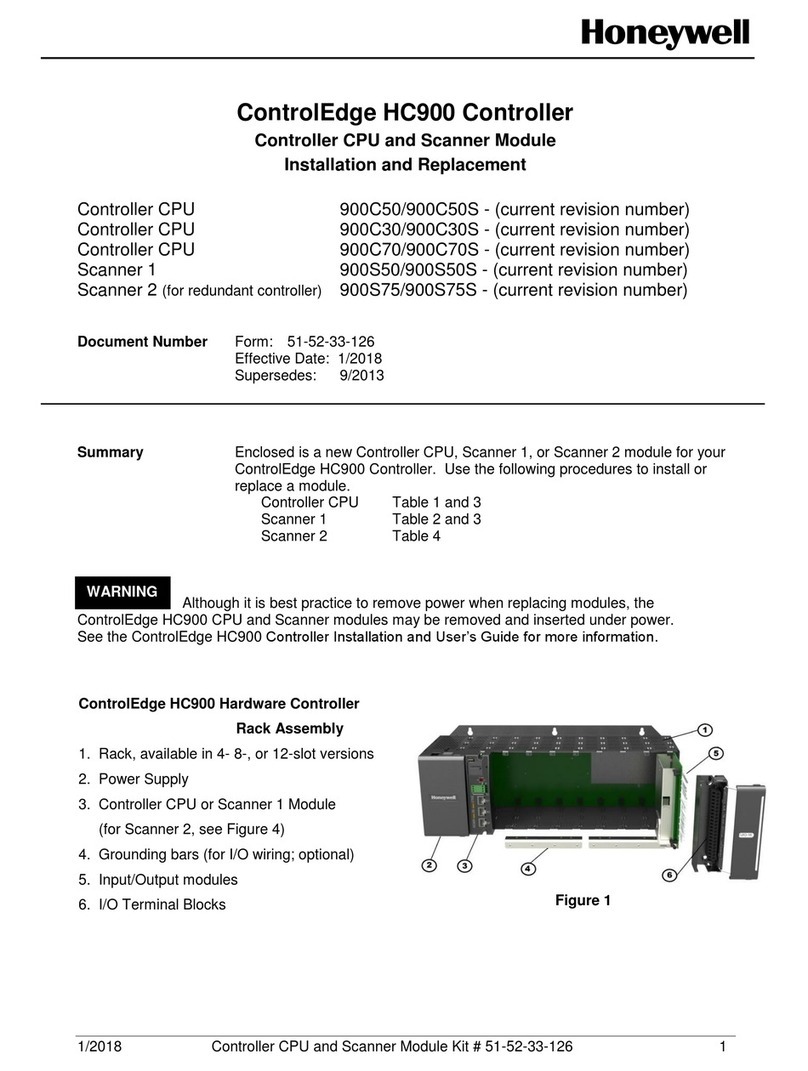

Honeywell HC900 Use and care manual

Honeywell

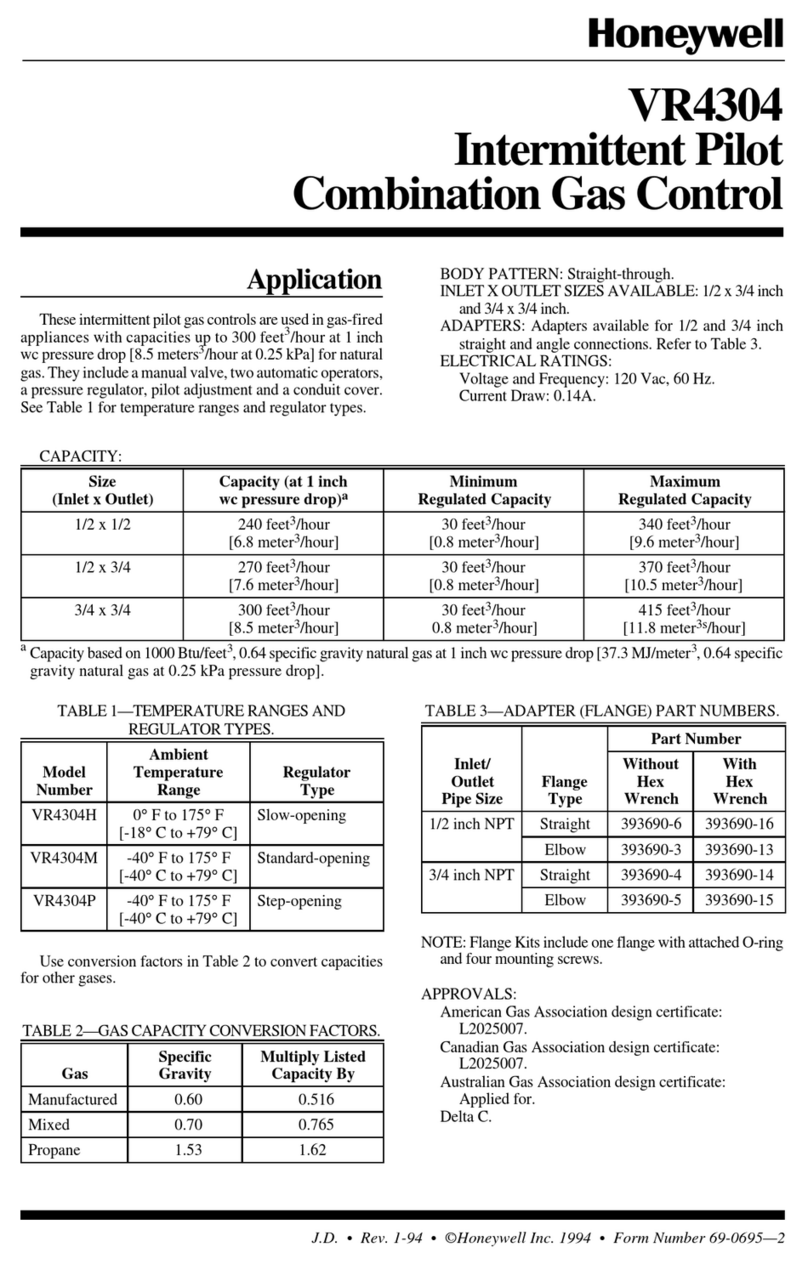

Honeywell VR4304 Series User manual

Honeywell

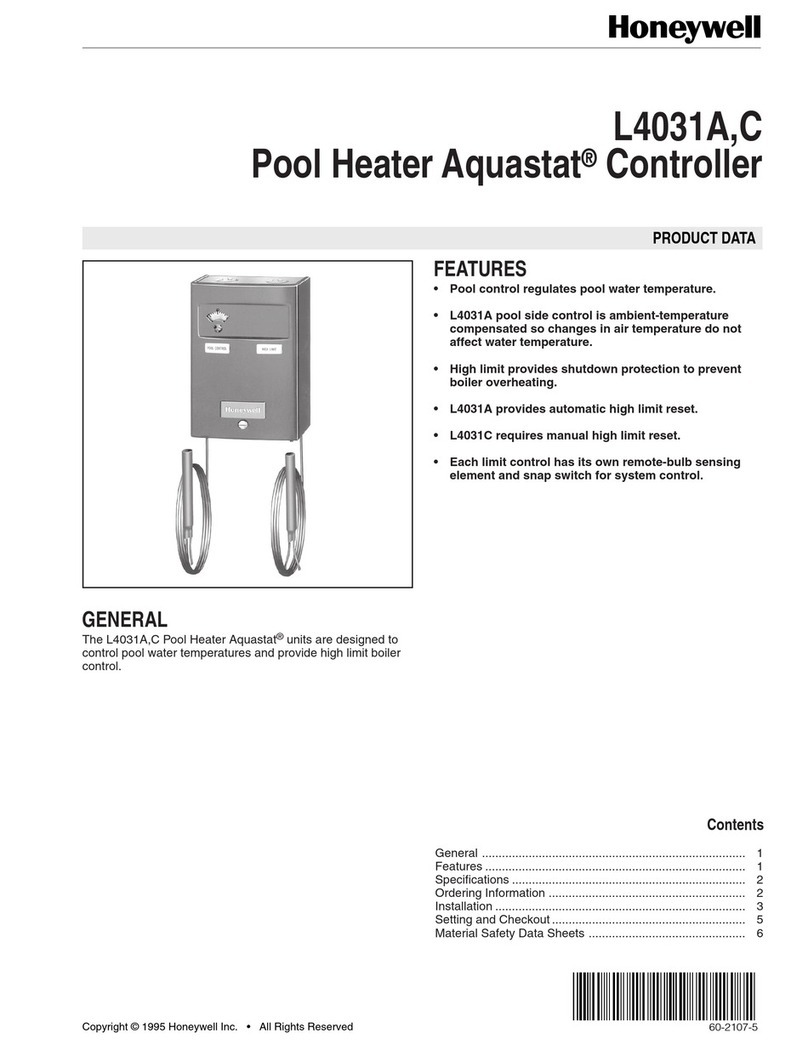

Honeywell C User manual

Honeywell

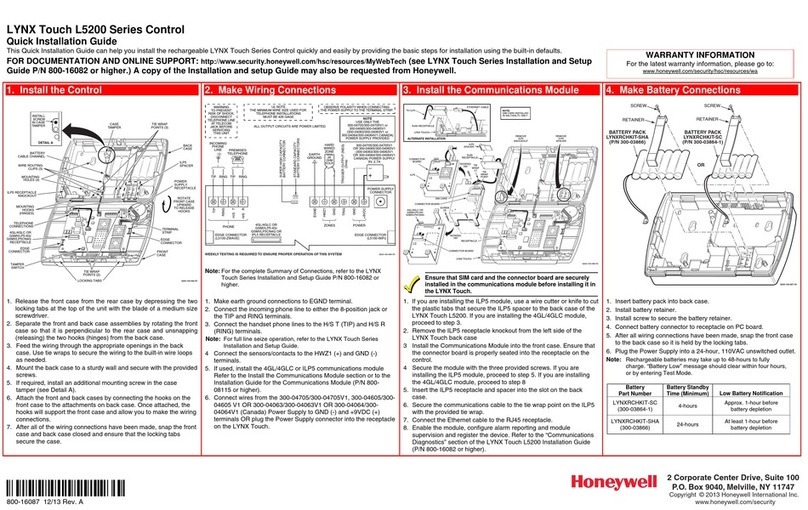

Honeywell LYNX Touch L5200 Series User manual

Honeywell

Honeywell CIPer 50 User manual

Honeywell

Honeywell HR 10 F User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions