10

DESCRIPTION OF THE CONTROLS

•Line button (1)

Whensettoposition“1”ON,thisbuttonenablesnormal

machine operation. Set to position “0” OFF, it disables

all machine functions.

•Regeneration button (2) (only for mod. CD-CRD-

SPD-SPRD)

Whenpressedwhilethemachineisoff,thisregenerates

the resins of the built-in decalcifier.

•Start button (3)

When pressed, this activates the normal washing

cycle. The light (5) goes out once the cycle has

terminated.

Draining condition (line off)

(on machines with drain pump only)

Press the button to manually drain the dishwasher.

•Tank level indicator (4)

Thiscomesonwhenthetankwaterreachesthepreset

level.

•Cycle indicator (5)

When on, this indicates that the cycle is in progress.

•Boiler temperature light (6)

Thiscomesonwhen theheatingelementfor the water

in the rinsing Boiler comes on and goes out once the

preset temperature has been reached.

• Cold rinse button (7) (only for C35 - SPB 35)

If pressed at the end of the washing, it allows the

cooling of the glasses.

ENG

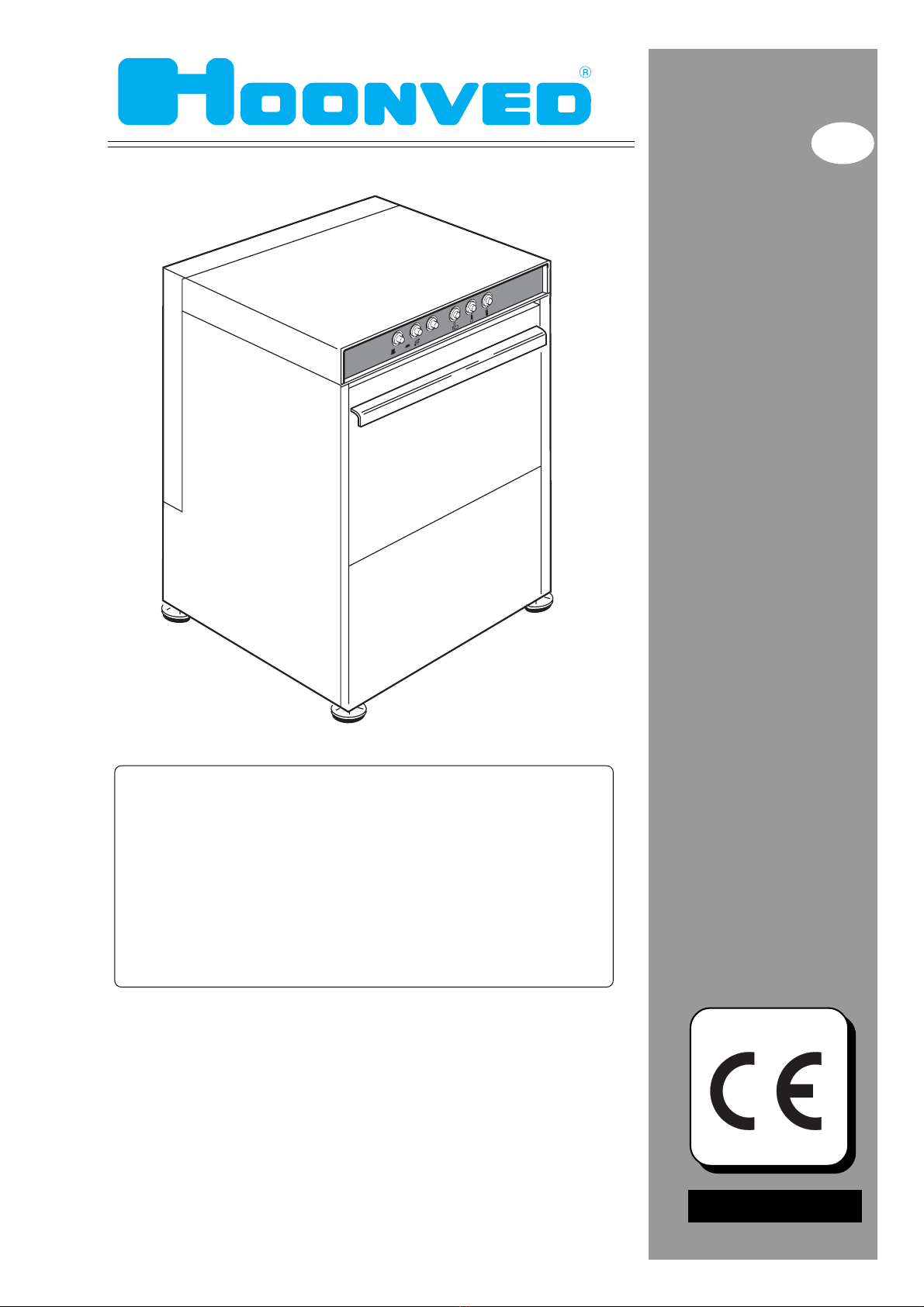

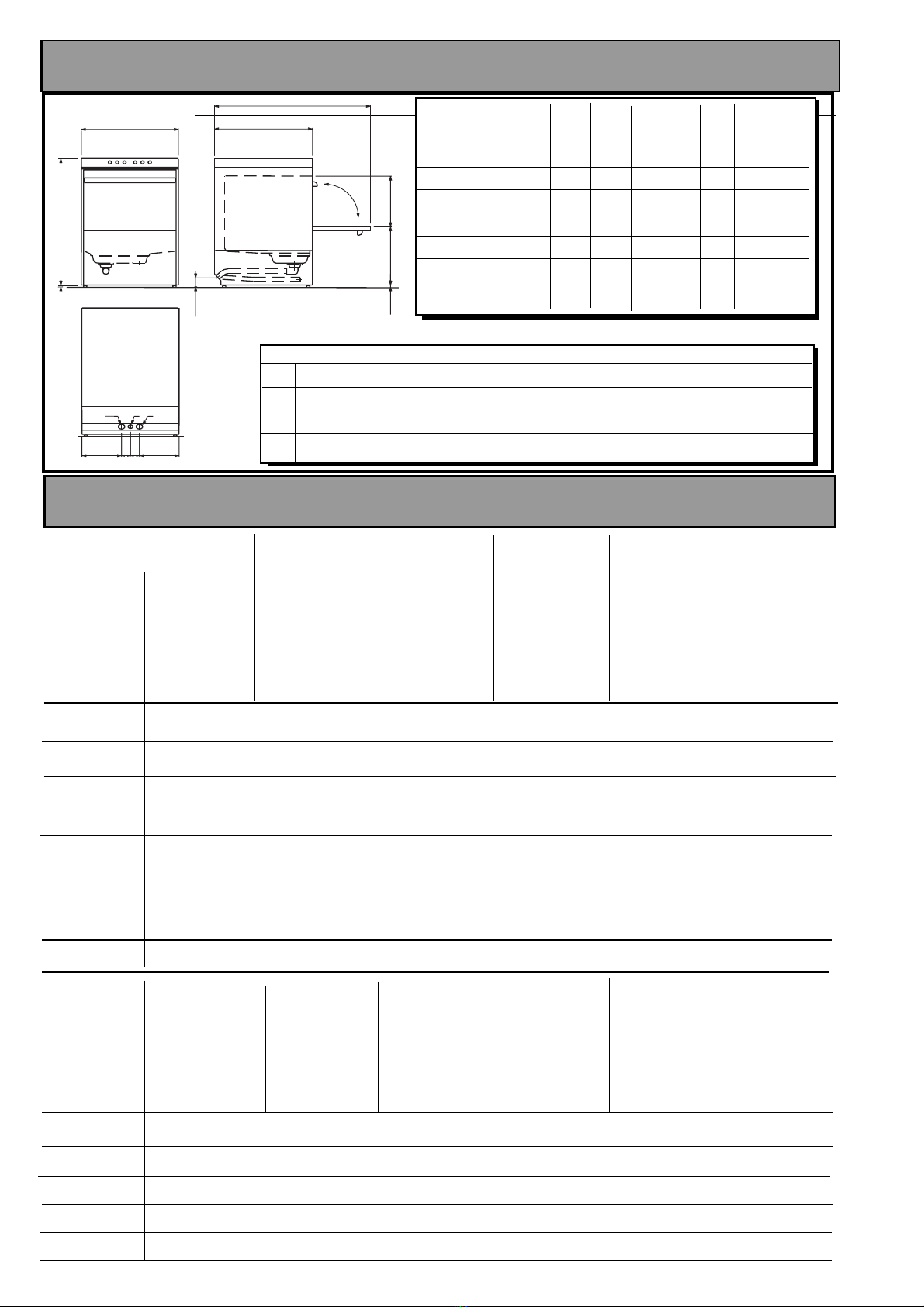

CRUSCOTTO COMANDI - CONTROL PANEL - PANNEAU DES COMMANDES

SCHALTBLENDE - PANEL DE MANDOS

LEGENDA

1) Pulsante di linea

2) Pulsante rigenera (Optional)

3) Pulsante di START

Pulsante Scarico (Optional)

4) Lampada livello vasca

5) Lampada ciclo

6) Lampada Boiler

7) Pulsante risciacquo a freddo

(Optional) solo per C 35-SPB 35

LEGEND

1) Line button

2) Regeneration button (Optional)

3) START button

Drain button (Optional)

4) Tank level indicator light

5) Cycle indicator

6) Boiler light

7) Cold rinse button (Optional) only

for C 35 - SPB 35

LEGENDE

1) Bouton de ligne

2) Bouton de régénération (In option)

3) Bouton de MARCHE

Buoton de Vidange (In option)

4) Lampe de niveau de la cuve

5) Lampe de cycle

6) Lampe du chauffe-eau

7) Bouton de rinçage a froid (In

option) seulement pour C 35 - SPB 35

ZEICHENERKLÄRUNG

1) Ein-/Austaste

2) Taste für regenerierung (extra)

3) Start - Taste

Ablauf - Taste (extra)

4) KontrolleuchtefürWasserstandimTank

5) Kontrolleuchte Zyklus

6) Kontrolleuchte Boiler

7) Taste für Klarspülen mit

Kaltwasser(Extra) nur bei C 35 - SPB 35.

START

0I

123456

LEYENDA

1) Tecla de línea

2) Botón regeneración (Opcional)

3) Tecla START

Tecla de Descarga (Opcional)

4) Lámpara nivel tanque

5) Lámpara ciclo

6) Lámpara calentador de agua

7) Botón enjuague frío (Opcional)

solo para C 35 - SPB 35.

C-CD-CR-CRD

SP-SPD-SPR

SPRD

START

0

I

17345

6

C 35

SPB 35