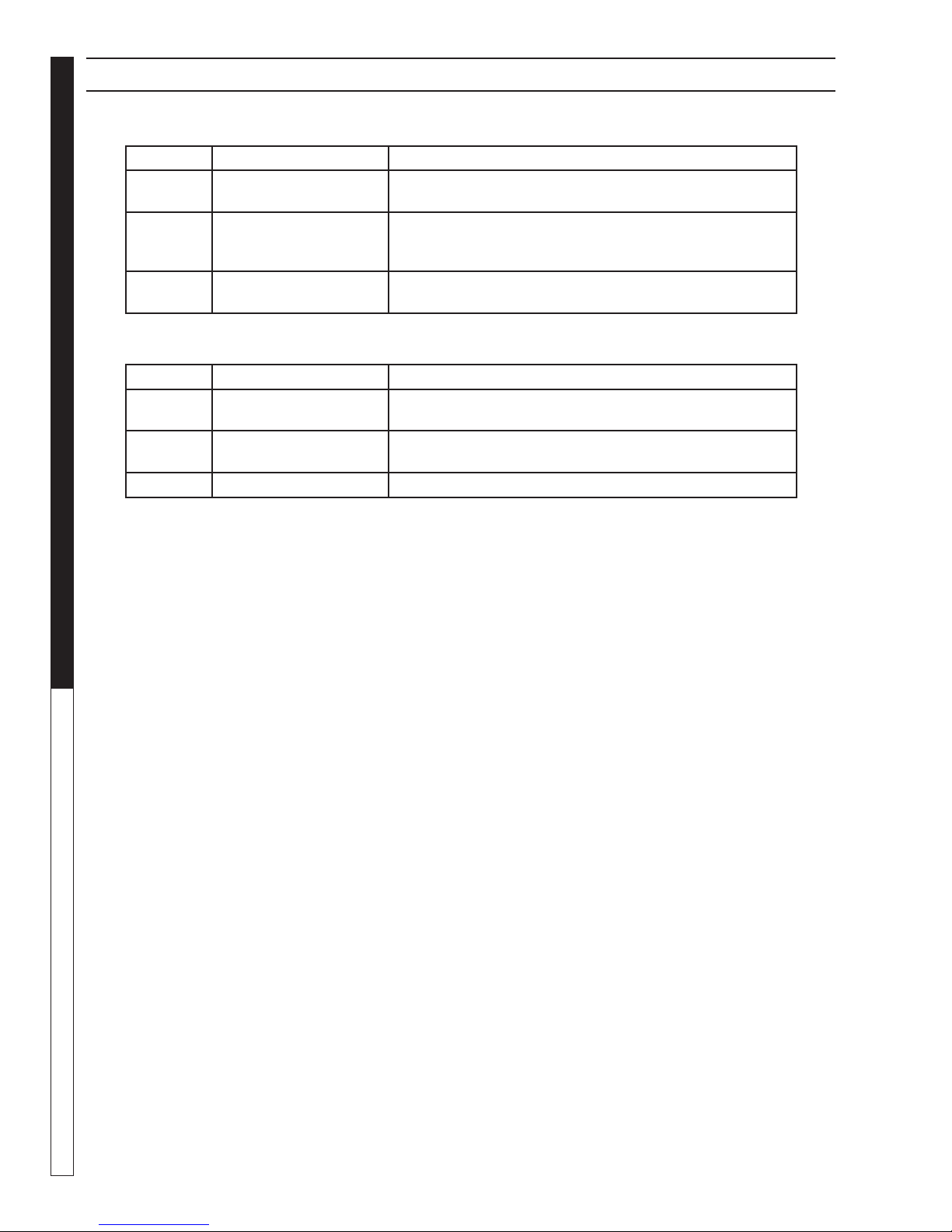

5832SS • 1.109-651.0

SPECIFICATIONS

Pump Volume At Pump Head: 9.5 GPM / 570 GPH

Pump Pressure At Pump Head: 2500 PSI

Burner Type: Natural Gas Fired, 939,890 BTU/Hr.

Machine Voltage: 230VAC/60Hz/3Ph

Total Machine Amperage:* 42 Amps

Rated Motor Amps: 50 Amps

Machine Weight: 1035 Lbs.

Shipping Weight: 1275 Lbs.

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5832SS-208 • 1.109-650.0

SPECIFICATIONS

Pump Volume At Pump Head: 9.5 GPM / 570 GPH

Pump Pressure At Pump Head: 2500 PSI

Burner Type: Natural Gas Fired, 939,890 BTU/Hr.

Machine Voltage: 208VAC/60Hz/3Ph

Total Machine Amperage:* 48 Amps

Rated Motor Amps: 61 Amps

Machine Weight: 1035 Lbs.

Shipping Weight: 1275 Lbs

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5835SS • 1.109-652.0

SPECIFICATIONS

Pump Volume At Pump Head: 9.5 GPM / 570 GPH

Pump Pressure At Pump Head: 2500 PSI

Burner Type: Natural Gas Fired, 939,890 BTU/Hr.

Machine Voltage: 460VAC/60Hz/3Ph

Total Machine Amperage:* 21 Amps

Rated Motor Amps: 25 Amps

Machine Weight: 1035 Lbs.

Shipping Weight: 1275 Lbs

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5836SS • 1.109-653.0

SPECIFICATIONS

Pump Volume At Pump Head: 9.5 GPM / 570 GPH

Pump Pressure At Pump Head: 2500 PSI

Burner Type: Natural Gas Fired, 939,890 BTU/Hr.

Machine Voltage: 575VAC/60Hz/3Ph

Total Machine Amperage:* 16 Amps

Rated Motor Amps: 19.8 Amps

Machine Weight: 1035 Lbs.

Shipping Weight: 1275 Lbs

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5732SS • 1.109-655.0

SPECIFICATIONS

Pump Volume At Pump Head: 7.8 GPM / 470 GPH

Pump Pressure At Pump Head: 3000 PSI

Burner Type: Natural Gas Fired, 720,450 BTU/Hr.

Machine Voltage: 230VAC/60Hz/3Ph

Total Machine Amperage:* 42 Amps

Rated Motor Amps: 50 Amps

Machine Weight: 1016 Lbs.

Shipping Weight: 1260 Lbs.

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5732SS-208 • 1.109-654.0

SPECIFICATIONS

Pump Volume At Pump Head: 7.8 GPM / 470 GPH

Pump Pressure At Pump Head: 3000 PSI

Burner Type: Natural Gas Fired, 720,450 BTU/Hr.

Machine Voltage: 208VAC/60Hz/3Ph

Total Machine Amperage:* 48 Amps

Rated Motor Amps: 61 Amps

Machine Weight: 1016 Lbs.

Shipping Weight: 1260 Lbs.

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5735SS • 1.109-656.0

SPECIFICATIONS

Pump Volume At Pump Head: 7.8 GPM / 470 GPH

Pump Pressure At Pump Head: 3000 PSI

Burner Type: Natural Gas Fired, 720,450 BTU/Hr.

Machine Voltage: 460VAC/60Hz/3Ph

Total Machine Amperage:* 21 Amps

Rated Motor Amps: 25 Amps

Machine Weight: 1016 Lbs.

Shipping Weight: 1260 Lbs.

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

5736SS • 1.109-657.0

SPECIFICATIONS

Pump Volume At Pump Head: 7.8 GPM / 470 GPH

Pump Pressure At Pump Head: 3000 PSI

Burner Type: Natural Gas Fired, 720,450 BTU/Hr.

Machine Voltage: 575VAC/60Hz/3Ph

Total Machine Amperage:* 16 Amps

Rated Motor Amps: 19.8 Amps

Machine Weight: 1016 Lbs.

Shipping Weight: 1260 Lbs.

Exhaust Stack Size: 12"

Machine Dimensions:

Length=51", Width=31", Height=63.4"

* Total Machine Amperage is based on the required horsepower for the given flow and pressure. Amps are measured with

standard incoming voltage of 208V, 230V, 460V and 575V. Actual amperage may differ due to incoming voltage.