•

•

•

SAFETY

SUMMARY

The following generalsafety precautions must

be

observed during

all

phases

of

operation, service,

and

repair

of

this instrument.

Failure

to

comply with these precautions

or

with specific warnings elsewhere

in

this manual violates safety standards

of

dnign,

manufacture,

and

intended use

of

the instrument. Hewlett-Packllrd Company assumes

no

liability

for

the

customer's failure to

comply

with these requirements.

BEFORE APPLYING POWER

Verify thatthe product is set

to

match the

available

line

voltage.

GROUND

THE

INSTRUMENT

This product is a Safety Class 1 instrument (provided with a

protective earth terminal).

To

minimize shock

hazard,

the

instrument chassis and cabinet must

be

connected to

an

electrical ground.

The

instrument must

be

connected tothe

ac

power supply mains through a three-conductor power

cable,

with

the third wire firmly connected

to

an

electrical ground

(safety ground) at the power outlet. Any interruption of the

protective (grounding! conductor or disconnection of the

protective earth terminal will cause a potential shock

hazard

that

could result

in

personal injury.

If

the instrument

is

to be

energized

.via

an external autotransformerforvoltage reduction,

be

certain

that

the autotransformer common terminal is

connected

to

the

neutral !earthed pole)

of

the

ac

power lines

(supply mains!. This instrument

is

equipped with a line filter

·to

reduce electromagnetic interference

(EMii,

and

must

be

connected

to

a property grounded receptacle

to

minimize

EMI.

FUSES ·

Fuses are contained inside the unit,

and

are

not

user-

replaceable.

Onlytrained service

personnel

should

replace

blown

fuses, and only after identifying

and

correcting the

problem

which caused

the

fuse(s)

to

blow.

DO NOT OPERATE

IN

AN EXPLOSIVE

ATMOSPHERE

Do

not

operate the instrument in the

presence

of flammable

gases or fumes.

KEEP

AWAY

FROM

LIVE CIRCUITS

Operating personnel

must

not

remove instrument

covers.

Component replacement and internal

adjClstments

must

be

made

by

qualified

service

pei-sonnel.

Do

not

replace

components

with

the power

cable

connected. Under certain conditions,

dangerous voltages may exist

even

with the power

cable

removed.

To

avoid injuries, always disconnect power,

discharge

circuits and remove external voltage sources before touching

components.

DO NOT SERVICE OR

ADJUST

ALONE

Do

not

attempt internal service oradjustment

unless

another

person, capable of rendering first aid and resuscitation,

is

present.

DO

NOT EXCEED

INPUT

RATINGS

Operation at line voltages or frequencies in

excess

of

those

stated

on

the

data

plate

maycause

leakage

currents

in

excess

of

3.5

mA

peak

.

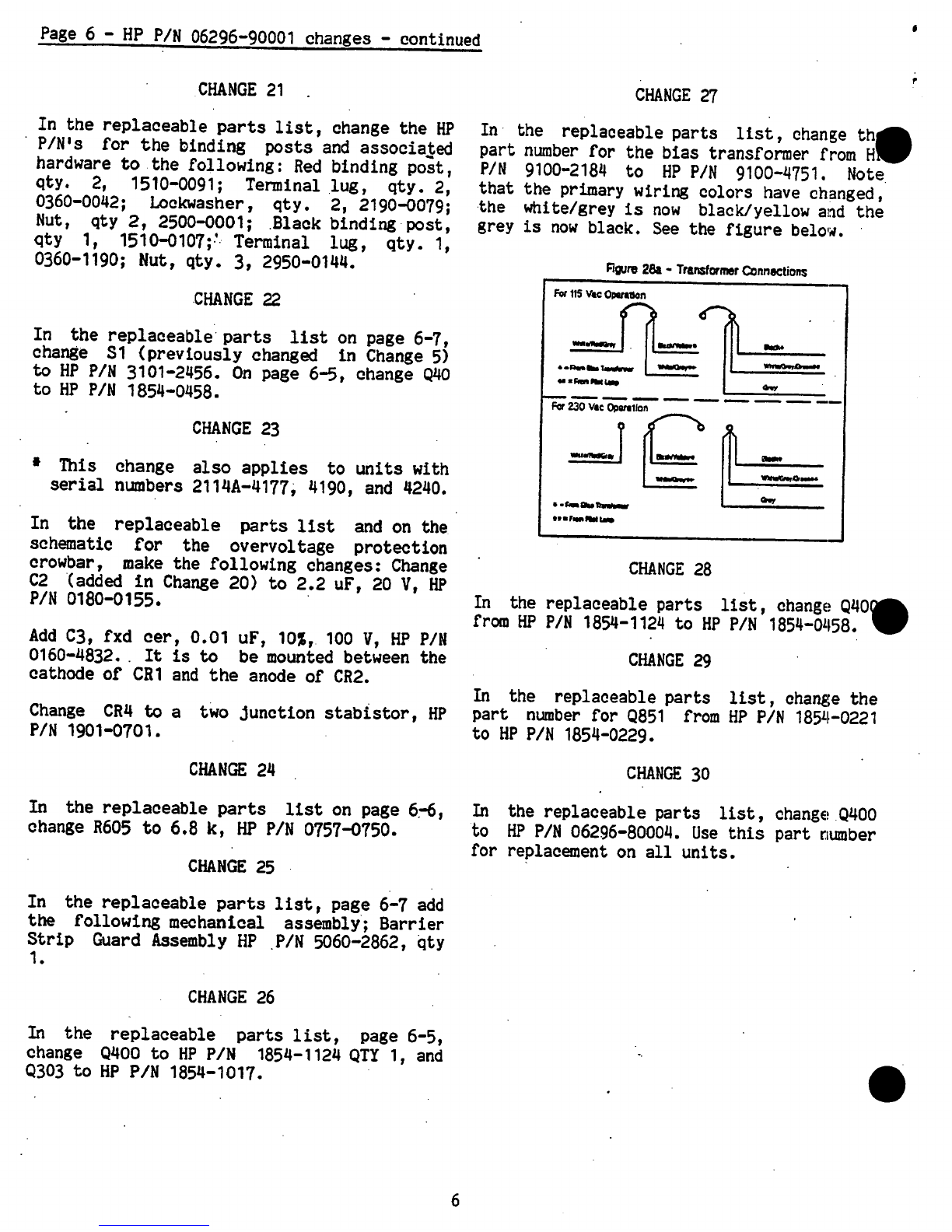

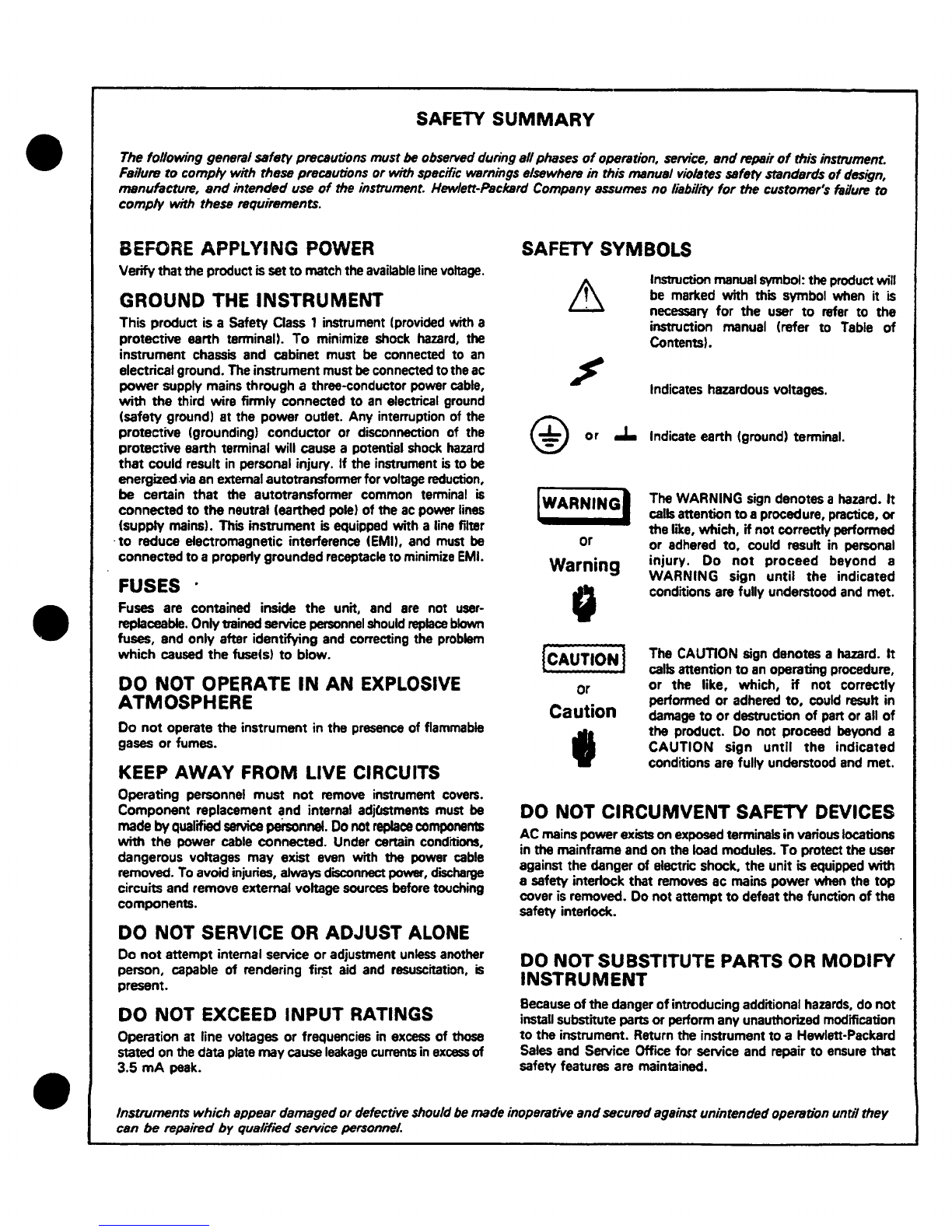

SAFETY SYMBOLS

Instruction manual symbol: the product will

be marked with this symbol when it is

necessary

for

the user

to

refer to the

instruction manual (refer to

Table

of

Contents).

Indicates hazardous voltages.

@

or

.I.

Indicate earth (ground) terminal.

or

Warning

0

(CAUTION!

or

Caution

I

The WARNING sign denotes a hazard.

It

calls attention

to

aprocedure, practice,

or

the like, which,

if

not correctly performed

or adhered to, could result in personal

injury.

Do

not

proceed

beyond a

WARNING sign

until

the

indicated

conditions are fully understood

and

met.

The

CAUTION

sign denotes a hazard.

It

calls attention

to

an

operating procedure,

or

the like, which,

if

not correctly

performed or adhered

to,

could result in

damage

to

or

destruction

of

part

or

all

of

the product. Do not proceed beyond a

CAUTION sign

until

the

indicated

conditions are fully understood

and

met.

DO NOT

CIRCUMVENT

SAFETY DEVICES

AC

mains powerexists

on

exposed terminals in various locations

in the mainframe and on the load modules.

To

protect the user

against the danger of electric shock, the unit is equipped with

a safety interlock that removes ac mains power when the

top

cover is removed. Do not attempt

to

defeat the function

of

the

safety interlock.

DO

NOT

SUBSTITUTE PARTS OR MODIFY

INSTRUMENT

Because

of

the danger

of

introducing additional

hazards,

do

not

install substitute parts

or

perform any unauthorized modification

to

the instrument. Return the instrument

to

a Hewlett-Packard

Sales

and Service Office for service and repair

to

ensure

that

safety features are maintained.

Instruments

which

appeardamaged

or

defective should

be

made inoperative

and

sscuredagainst unintendedoperation unrilthey

can

be

repaired

by

qualifiedservice personnel.