Bad connections or loose screws will lead to unnecessary heating up of the clamps, the

performance of the blade will be adversely affected and the heating up of one or both of the

clamps can lead to the housing becoming burned.

Functional description

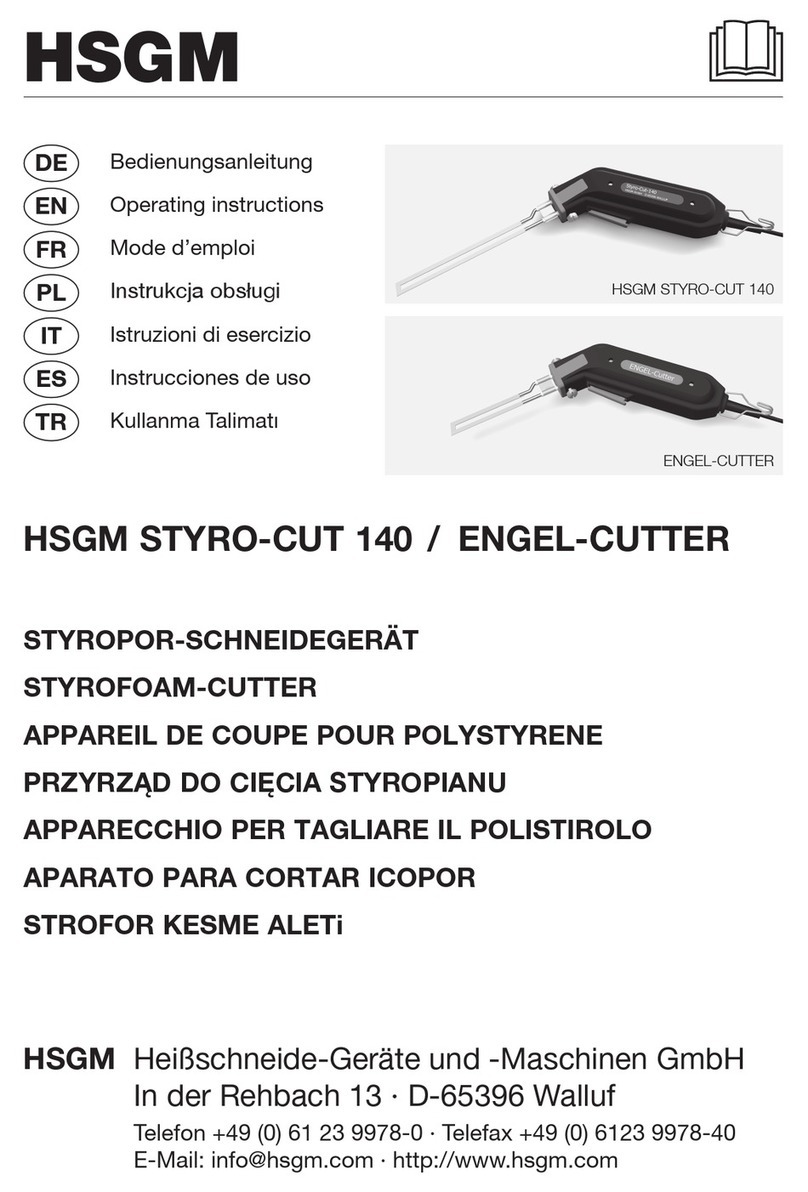

In conjunction with an appropriate blade, the Heat-Cutter shall be used only to separate or to cut synthetic fabric or cords,

ropes, bands and belting fabric. No other materials may be cut.

The blade, which is directly heated via an electronically transformer, is heated to 600 °C (1230°F) within 6 to 8 seconds.

All the synthetically material which makes contact with the blade will melt.

This causes an uninterrupted, welded edge to form. The edges welded like this will not fray.

An electronic current limiter protects the Heat-Cutter device against overloading and against a short circuit at the blades.

In the event of overloading (e.g. short circuit or wrong adjustment) the output will be turned down.

Only after the overloading has been corrected will the device be operable again.

In the event of a permanent overload (e.g. non-permitted continuous operation) an integrated temperature limiter will

separate the device from the mains power supply. After a cooling time of approx. 15 minutes the device can be used again.

This device is not for continuous operation, only for intermittent operation.

12s/48s on the type plate gives, at the front of the slash, the operating period provided a appropriate heat

sink is available and, after the slash, the pause period for which the device should be switched off.

Commissioning

Check that the mains voltage corresponds to that given on the type plate.

Depending on the type of the work to be carried out and the thickness of the material, various blades are available. In this

context please observe the Permissible Blades, See Page 6.

Only insert the blade while the device is switched off.

Now insert the plug of the Heat-Cutter device into a mains socket.

The device is switched on by pressing the switch lever.

The red LED-lamp is illuminated.

After a heating time of several seconds the required blade temperature is reached.

After the work is completed the device can be put away. The switch lever automatically returns to its limiting position and

switches the device off.

The switch lever must not be mechanically locked or electrically bridged.