HSGM Heißschneide-Geräte

u.- Maschinen GmbH

Phone : +49 (0) 6123 9978-0 B-03-VW-D.DOC

Fax : +49 (0) 6123 9978-40 Status: 28.01.2017

Email: info@hsgm.com Printed: 16.05.2018

http://www.hsgm.com

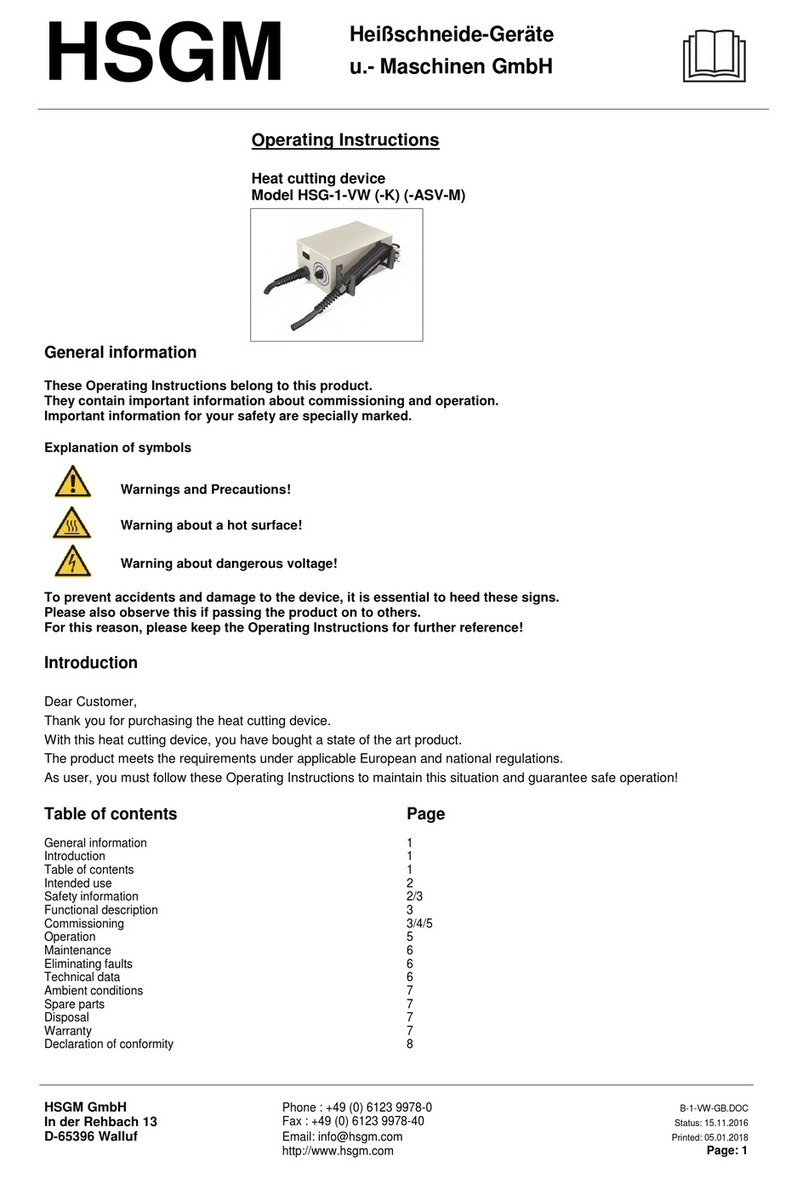

Securing the support bracket on the housing: only M4 x 10 screws with washer and toothed washer may be used to

secure the support bracket.

Check whether the available mains voltage conforms to the voltage specified on the type plate.

Various cutting blades are available depending on the work at hand and the thickness of the material. Please refer

here to the heat cutting machines / cutting blades data sheet.

The cutting blade may only be inserted when the machine is switched off.

The toggle for the on/off switch is set to -0- .

This means: the signalling lamp on the on/off switch is not lit up.

Turn the power control dial to the left to the min. position -0- .

Secure the cutting blade in the blade holder.

Caution !

To guarantee perfect electrical continuity, it is important to ensure the cutting blade is screwed tight when

inserted. Poor connections or loose screw connections result in unnecessary heating of terminals, the

cutting blade output is reduced, and the heating of one or both terminals may damage the blade holder.

After activating the on/off switch, the machine is ready for use and the stand-by heat switched on.

This means: The signalling lamp on the on/off switch is lit up.

The cutting blade already heats up to approx. 100 -150 °C depending on the model.

Determining the temperature setting on the dial:

A specific temperature is needed in line with the material, thickness and cutting speed.

This setting is made using the temperature dial. After pressing the switch lever on the blade holder, the actual

working heat set using the power control dial (= temperature dial) is added to the stand-by heat.

After a few practice cuts, the operator will quickly get a feel for adjusting the cutting temperature and guiding the

blade holder with the cutting blade.

The effective settings for the power control dial (= temperature dial) should be determined empirically, because the

power needed by the cutting blades depends greatly on the type and thickness of the material to be cut, and is

therefore subject to strong fluctuations, especially when cutting shapes (round, oval, square, angular etc.) and with

respect to the length of the lead (power cable) between the transformer (housing) and blade holder (standard is

2m).

Setting

-Switch the machine on as described above.

-Activate the switch and keep it pressed.

-Turn the temperature dial slowly in a clockwise direction

until the cutting blade inserted is dark red.