0912 3

FA 490.1

Danger of injury

Do not reach into the paper feed

opening.

Splinters can cause injury

Wear protective goggles when de-

stroying diskettes, CDs and hard

credit cards.

Danger of injury during intake

Do not go near the paper feed open-

ing with long hair, loose clothing, ties,

scarves, necklaces, bracelets etc.

Do not destroy any material which

might become tangled, such as tapes,

binder ties or foil.

Switch off the shredder and pull

out the power plug before moving

or cleaning the shredder, or any other

task outside its normal scope of use.

Maintenance and service tasks may

only be performed by HSM customer

service and service engineers of our

dealers.

1 Proper use, warranty

The document shredder is designed for destroying paper

and cardboard, as well as store cards, credit cards, CD-

ROMs and floppy discs. Its sturdy drive mechanism is not

damaged by paper clips and staples.

Our general business conditions are applicable. We pro-

vide a one year warranty for the document shredder. The

warranty period is 6 months when used in multiple shifts.

This warranty excludes wear, damage due to improper

handling, natural depreciation, and actions taken by third

parties.

2 Safety instructions

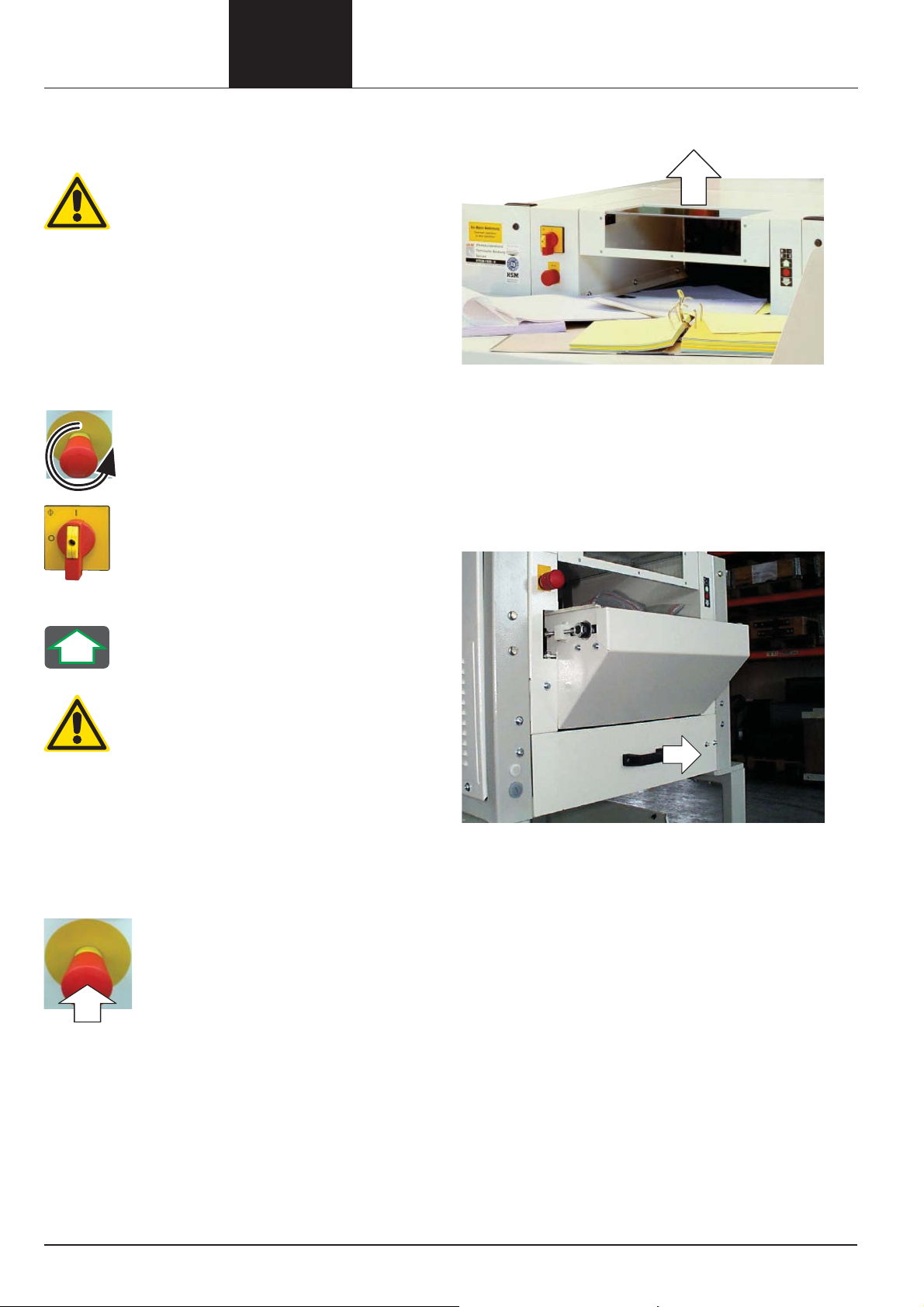

Caution:

It is prohibited to operate one only machine

of a combination-version machine. Only

the combination of document shredder and

HSM baling press fulfils the requirements of

EN 294 (Safety clearances).

• Read the operating manual before starting up the

shredder.

• Do not remove or modify safety devices which guar-

antee the safe operation of the machine.

• Observe all safety instructions attached to the ma-

chine.

• The shredder may not be operated by anyone under

16 years of age.

• Carry out inspection and maintenance regularly.

• Switch off the shredder, disconnect the power plug

and call customer service in the following circum-

stances:

- power cables or plugs are damaged

- liquid has entered the shredder

- the shredder has been exposed to rain

- the machine does not work properly despite the

operating manual having been observed

- the shredder has been damaged

• No platforms or other raised surfaces may be placed

near the shredder if they encroach on the specified

safety clearances.

Operating controls for your safety

Emergency stop button

In the event of danger, press the

emergency stop button immediately.

This switches off the shredder, and

stops the cutting block and feed belt.

Main switch (only Solo-version)

In the event of danger, turn the main

switch to “0”.

You can secure the main switch in

this position with a padlock to prevent

restarting.