Page 3 of 3

3940 Dr. Martin Luther King Drive

St. Louis, MO 63113

P/N 00911678 FORM NO. K1007 R9/15 ECO-7-019-15

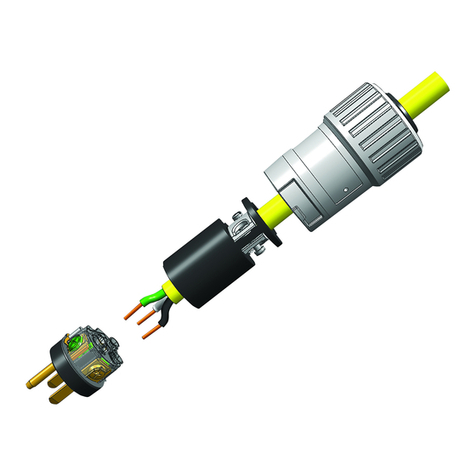

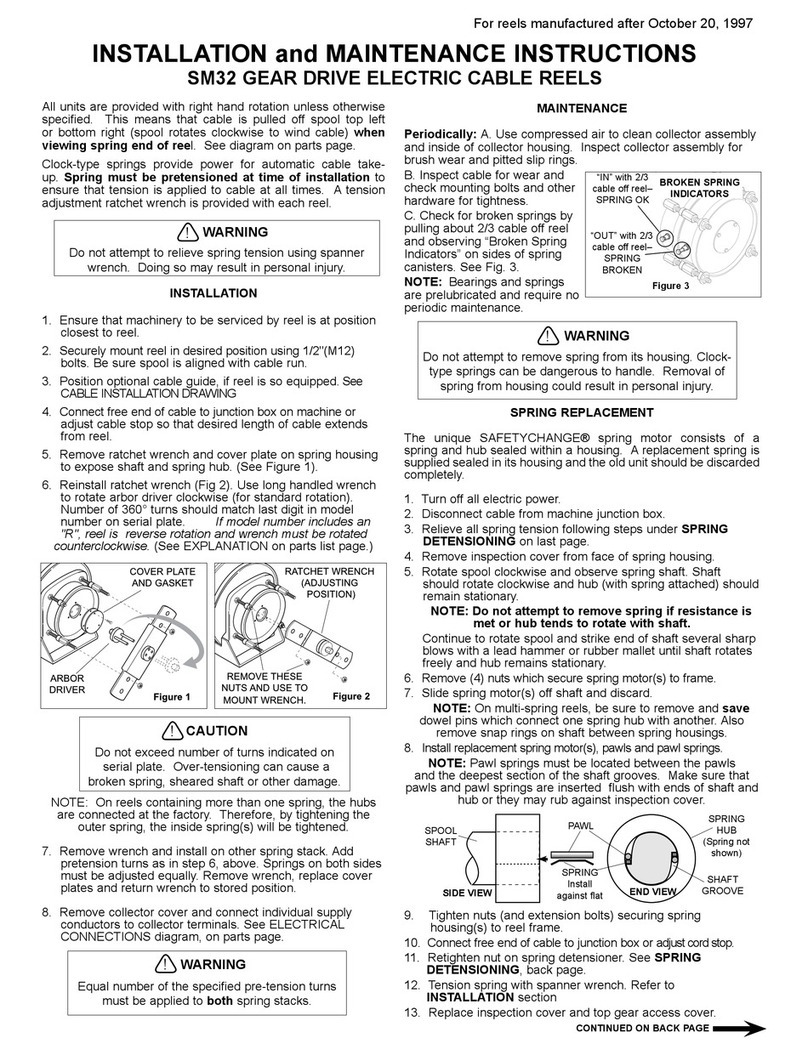

Figure 1

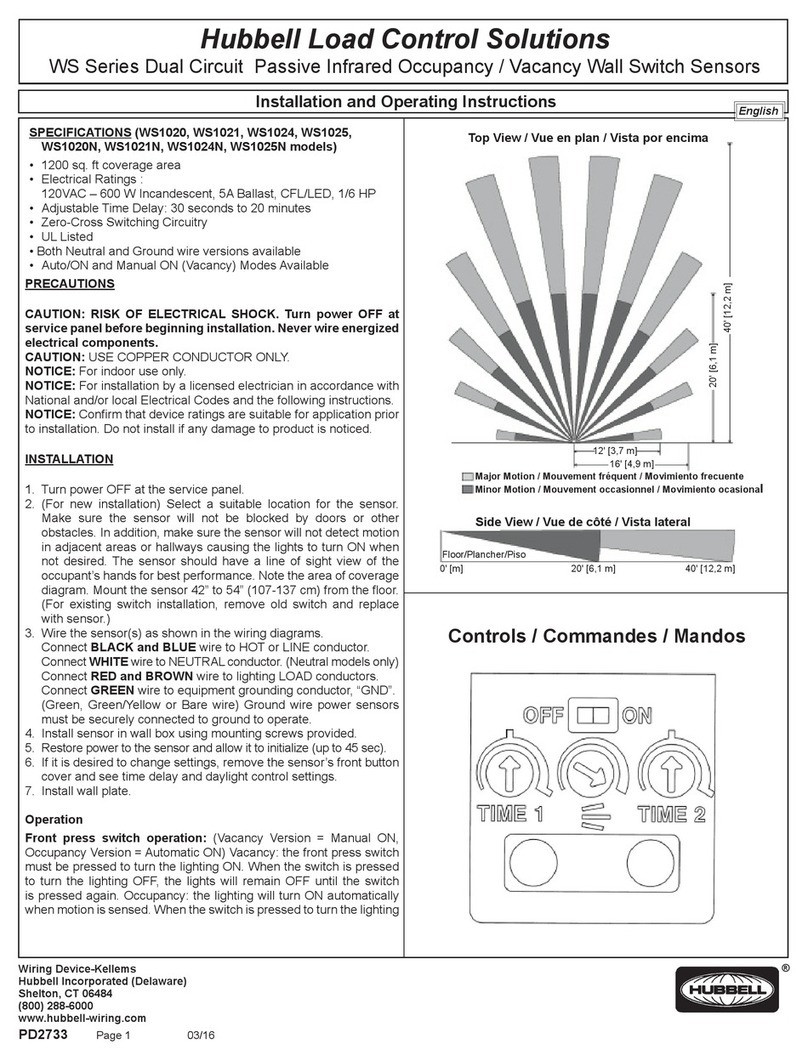

“QW” TERMINAL CONNECTIONS

4. Check the ange surfaces of both the box and the

receptacle cover to be sure they are clean, smooth;

free of nicks, scratches, dirt or any foreign particles

that would prevent a proper seal. Apply a light coating

of Killark “LUBG” lubricant to the anges and , after

pushing wiring into box, install cover to box, using the

(4) screws provided. Tighten the screws to 5 ft. lbs.

torque. After tightly bolting the cover assembly to the

box, the box to cover ame joint should be checked

with a 0.0015” thick feeler gauge, such that the gauge

will not enter the joint more than 1/8” at any point.

2. OPERATIONAL DATA

NOTE: UGRx receptacles WILL NOT operate with

ordinary plugs; UGP series plugs must be used. See

UGP instruction sheet K1377 for more information.

1. Lift receptacle door and insert plug all the way into the

receptacle.

2. Turn plug to clockwise limit (45°). This closes internal

contacts and completes circuit.

3. Release plug. Plug will move outward to “LOCK”

position. Check by trying to turn plug without pushing

inward; plug should not turn.

4. To remove plug, push plug inward and turn to counter-

clockwise limit (45°). Pull plug straight out.

UGRO…QW WIRING (See Figure 1) :

NOTE: Use only copper wire with this device (10, 12

or 14 AWG). Recommended wire strip length – ½

inch nominal (wire strip gauge also available on the

QW terminal cover). Loosen all (3) Terminal Contact

Screws and insert wire through the Wiring Entrance

holes, into proper terminals: Green lead (Ground)

to terminal with ground mark & Green screw head;

White (Neutral) lead to terminal with Silver screw

head (125V. only); Black and/or Red [Line lead(s)]

to terminal(s) with Brass screw head. Hand tighten

terminal screws (recommended torque 8 in.-lbs.

3. MAINTENANCE DATA

These receptacles require no maintenance other than

a periodic cleaning and a check for damage and/or

loose fasteners. These items should be performed on

a regular basis, determined by the environment and

usage.

WARNING: Disconnect and Lock Out supply circuit

before starting maintenance work.

1. To clean receptacle it is recommended that a soft,

non-metallic bristle brush be used.

2. Check tightness of all accessible screws.

3. Inspect the entire assembly for damage and/or wear.

Consult Killark factory for availability of replacement

parts and discontinue use of the equipment until

repairs are made.