2

Table of Contents

Safety Information................................................................. 2

Warranty................................................................................. 2

Pre-Operation......................................................................... 3

Before Assembly and Operation ........................................ 3

Specications.................................................................... 3

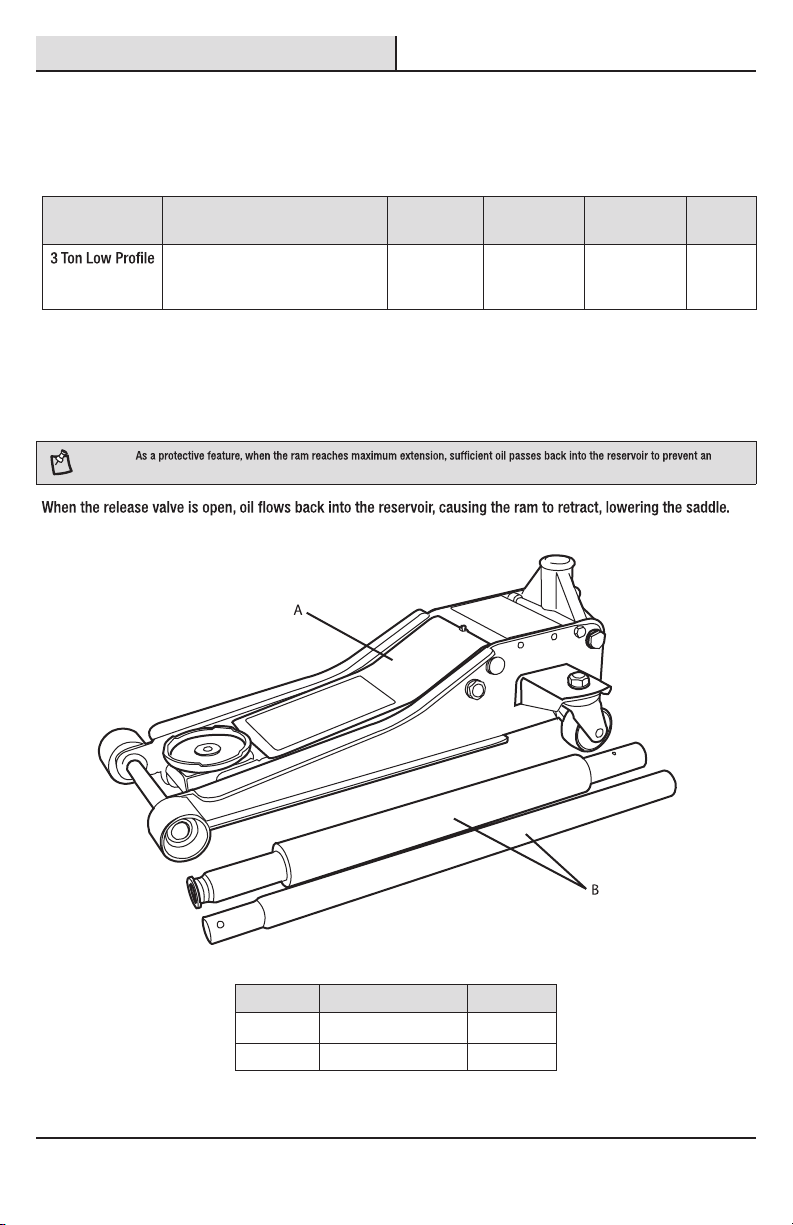

How It Works ..................................................................... 3

Garage Jack Package Contents......................................... 3

Jack Operation....................................................................4-5

Tool Set Up ............................................................................. 5

Attaching the Handle......................................................... 5

Bleeding ............................................................................ 5

Adding Oil.......................................................................... 5

Care and Cleaning ................................................................ 6

Inspection.......................................................................... 6

Maintenance ......................................................................... 6

Replacing Hydraulic Jack Oil............................................. 6

Lubricating the Jack.......................................................... 6

Storing the Jack ................................................................ 6

Cleaning the Jack.............................................................. 6

Troubleshooting ..................................................................... 7

General Operation.................................................................. 8

Lifting ................................................................................ 8

Lowering ........................................................................... 8

Exploded View........................................................................ 9

Safety Information

READ AND SAVE THESE INSTRUCTIONS

1. Read, understand, and follow all instructions before

operating this device prior to use.

2. Do not overload this jack beyond the rated capacity.

3. This jack is designed for use only on hard level

surfaces capable of sustaining the load. Use on

other than hard level surfaces can result in jack

instability and possible loss of load.

4. This is a lifting device only. Immediately after

lifting, support the vehicle with jack stands.

5. Inspect the jack prior to each use. Do not attempt

use if the unit is broken, bent, cracked, or has

missing and/or damaged parts. Replace broken,

bent, cracked, missing and/or damaged parts, and/

or missing labels, warnings and/or decals with

factory authorized parts prior to use.

DANGER: Because of the potential hazards associated

with the misuse of equipment of this type, no alterations

shall be made to the product without written authorization

of the manufacturer or supplier.

WARNING: Do not get under or allow anyone under the

vehicle until it has been supported by jack stands.

WARNING: For your safety and to prevent injury, use the

service jack for lifting purposes only.

WARNING: This jack is a lifting device only. It is not

a support device. NEVER place yourself under or near

a raised vehicle supported by a jack. Immediately after

lifting, support the vehicle with jack stands or other

appropriate means.

CAUTION: Do not move or dolly the vehicle while on

the jack.

CAUTION: Any jack that appears to be damaged or has

worn parts should be removed from service immediately.

IMPORTANT: Lift only on areas of the vehicle as

specied by the vehicle manufacturer. Use the vehicle

manufacturer’s instructions on proper lifting.

NOTE: Center the load on the saddle prior to lifting.

NOTE: Use of garage and bottle jacks on sea vessels is

prohibited.

NOTE: Some vehicles require an adapter to properly

engage the frame for lifting

NOTE: Failure to heed these warnings may result in

personal injury and/or property damage.

Warranty

The manufacturer warrants the products to be free from defects in materials and workmanship for a period of

one (1) year from the date of purchase. This warranty applies only to the original consumer purchaser and only to

products used in normal use and service. If this product is found to be defective, the manufacturer’s only obligation,

and your exclusive remedy, is the repair or replacement of the product at the manufacturer’s discretion, provided

that the product has not been damaged through misuse, abuse, accident, modications, alteration, neglect, or

mishandling. This warranty shall not apply to any product as a result of an accident, misuse, abuse, negligence,

alteration, faulty installation, or any other failure not relating to faulty material or workmanship. This warranty

shall not apply to the nish on any portion of the products such as surface and/or weathering, as this is considered

normal wear and tear.

The manufacturer does not warrant and specially disclaims any warranty, whether express or implied, of tness for

a particular purpose, other than the warranty contained herein. The manufacturer specically disclaims any liability

and shall not be liable for any consequential or incidental loss or damage, including but not limited to any labor/

expense costs involved in the replacement or repair of said product.

Contact the Customer Service at 1-888-HD-HUSKY or visit www.huskytools.com.