Husky 72WB01SS-THD User manual

Other Husky Tools Storage manuals

Husky

Husky H347TR User manual

Husky

Husky ERZ7824W-1 User manual

Husky

Husky HMT406B User manual

Husky

Husky HPRO72MWC20BLK User manual

Husky

Husky H52CH6HDV3WHT User manual

Husky

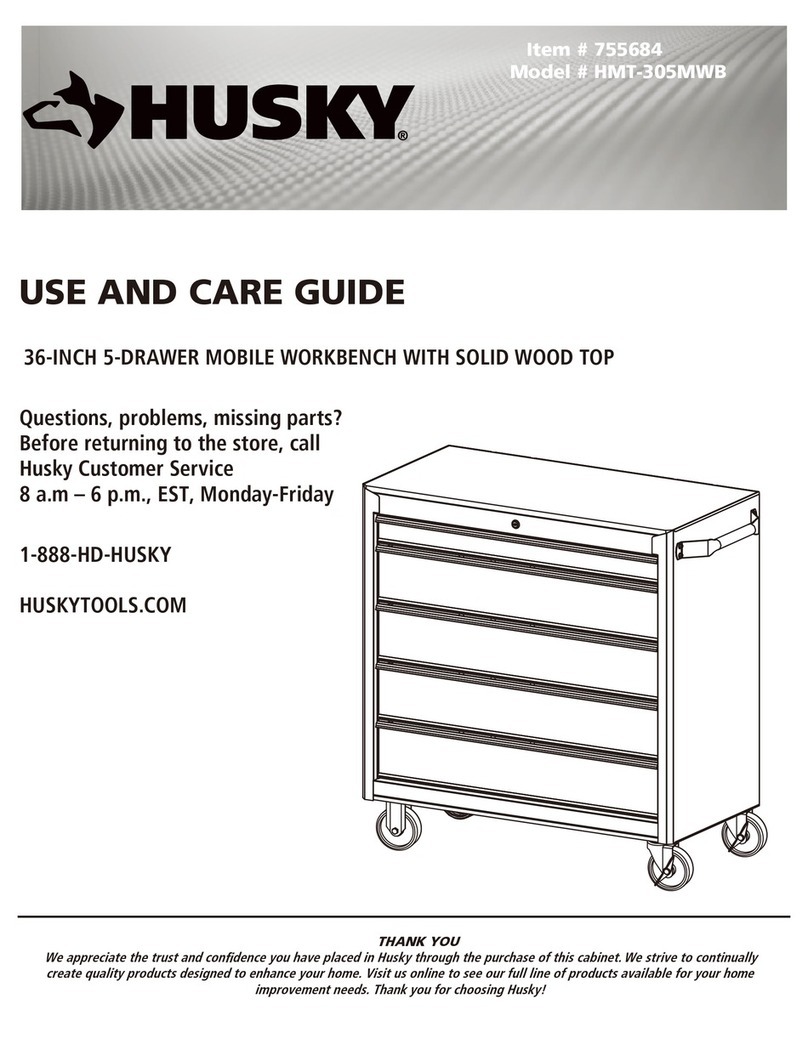

Husky HMT-305MWB User manual

Husky

Husky H52CH6HD User manual

Husky

Husky H72MWC10BLK-SC User manual

Husky

Husky H6CH36LEG User manual

Husky

Husky H48JSB User manual

Husky

Husky HBR782478W4 User manual

Husky

Husky H40CH4TR6 User manual

Husky

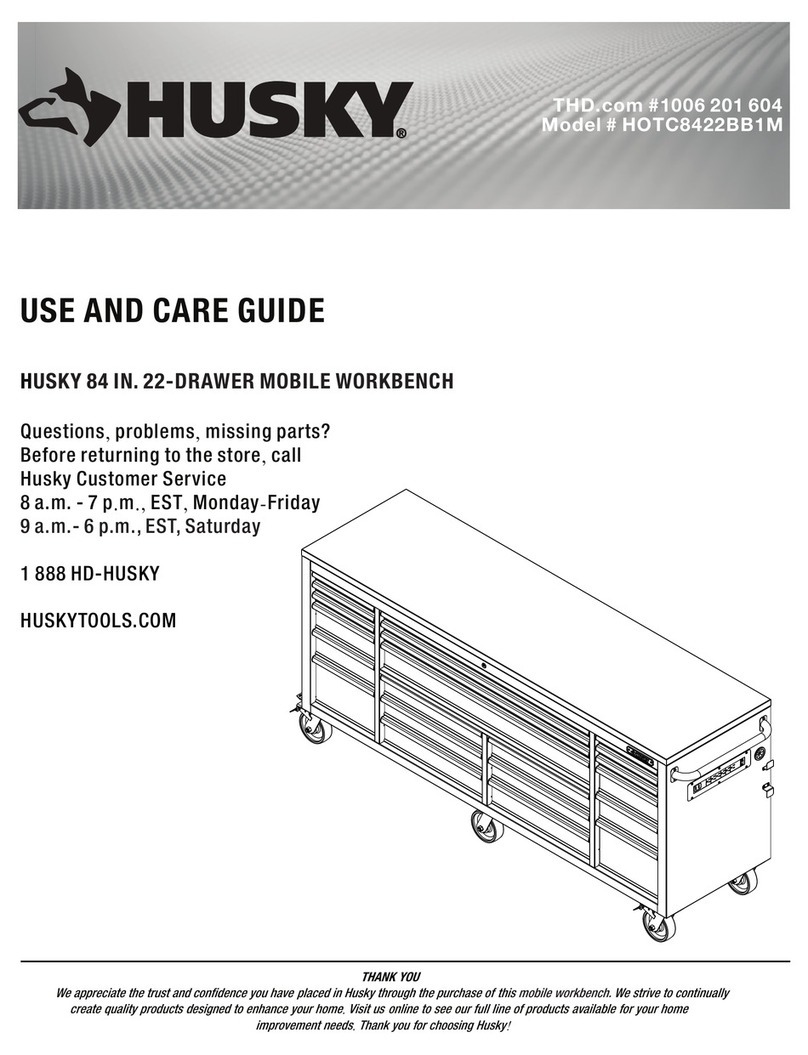

Husky HOTC5618BD1S User manual

Husky

Husky H46MWC9XD User manual

Husky

Husky H27CH5TR4BGK User manual

Husky

Husky HOME2801B12 User manual

Husky

Husky HOTC5213B1OS User manual

Husky

Husky HOTC7218B12M User manual

Husky

Husky HOTC5623BL2S User manual

Husky

Husky H4TR1 User manual

Popular Tools Storage manuals by other brands

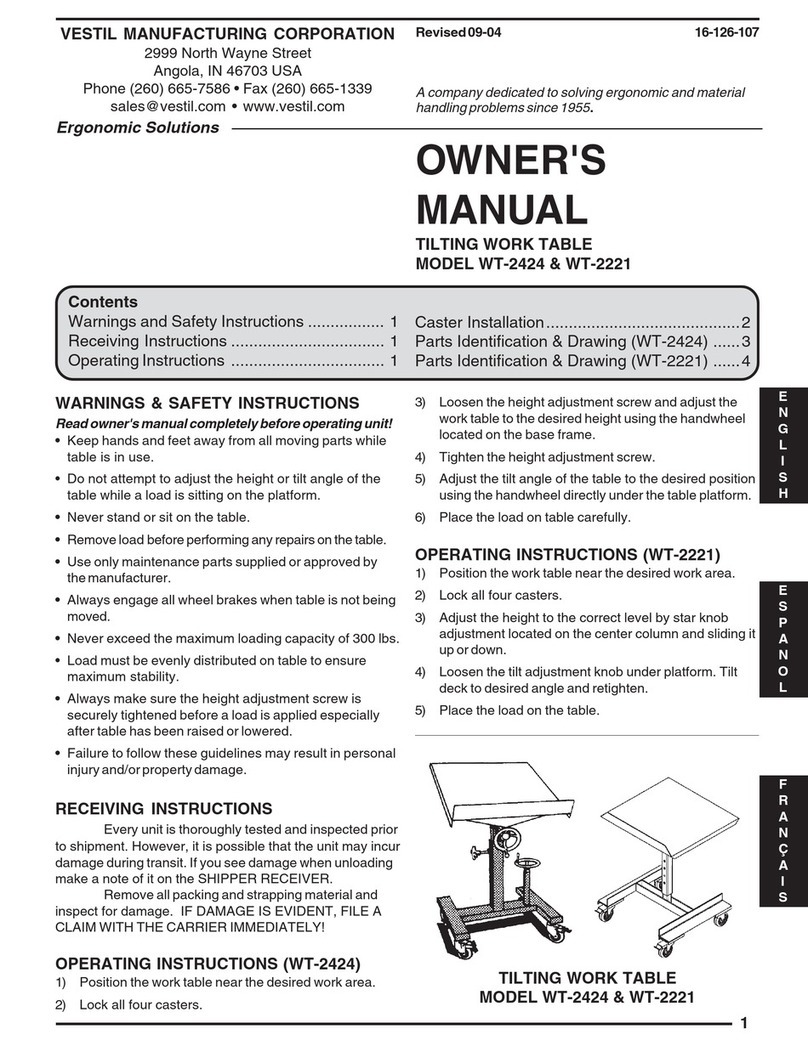

Vestil

Vestil WT-2424 owner's manual

Kendall Howard

Kendall Howard ESDW-9630-1000 owner's manual

Ryobi

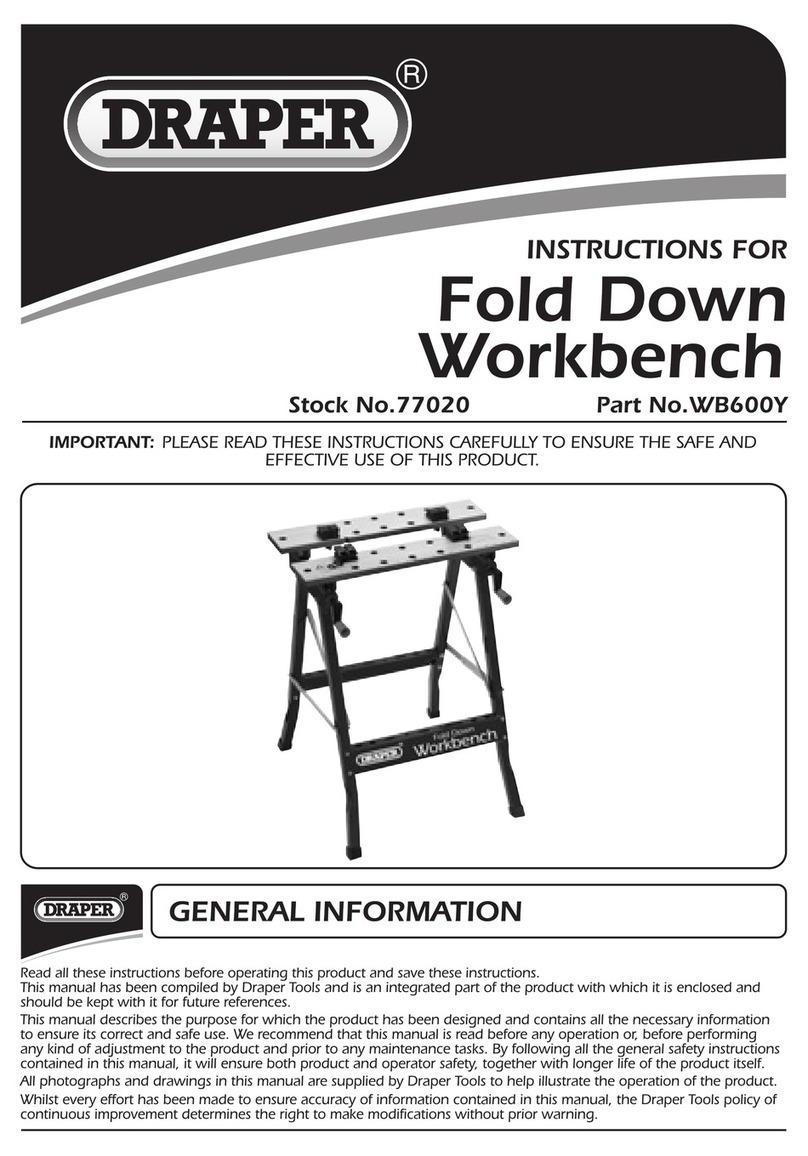

Ryobi RWB03 Original instructions

Scheppach

Scheppach ts 2100 Translation from original manual

DIVERSIFIED WOODCRAFTS

DIVERSIFIED WOODCRAFTS SHAIN GSB-6024 Assembly instruction

Cassese

Cassese CS200 CART user & parts manual

Cornwell Tools

Cornwell Tools CTB360AKBK Assembly instructions

Workzone

Workzone 99609 Assembly instructions

Stanley

Stanley STST83800-1 instruction manual

Perel

Perel ROLLER SHUTTER STORAGE CABINET Assembly instructions

BGS technic

BGS technic 4107 manual

Tennsco

Tennsco RXHS-962484 Assembly Instructions/Parts Manual