Page 8 of 20 pages

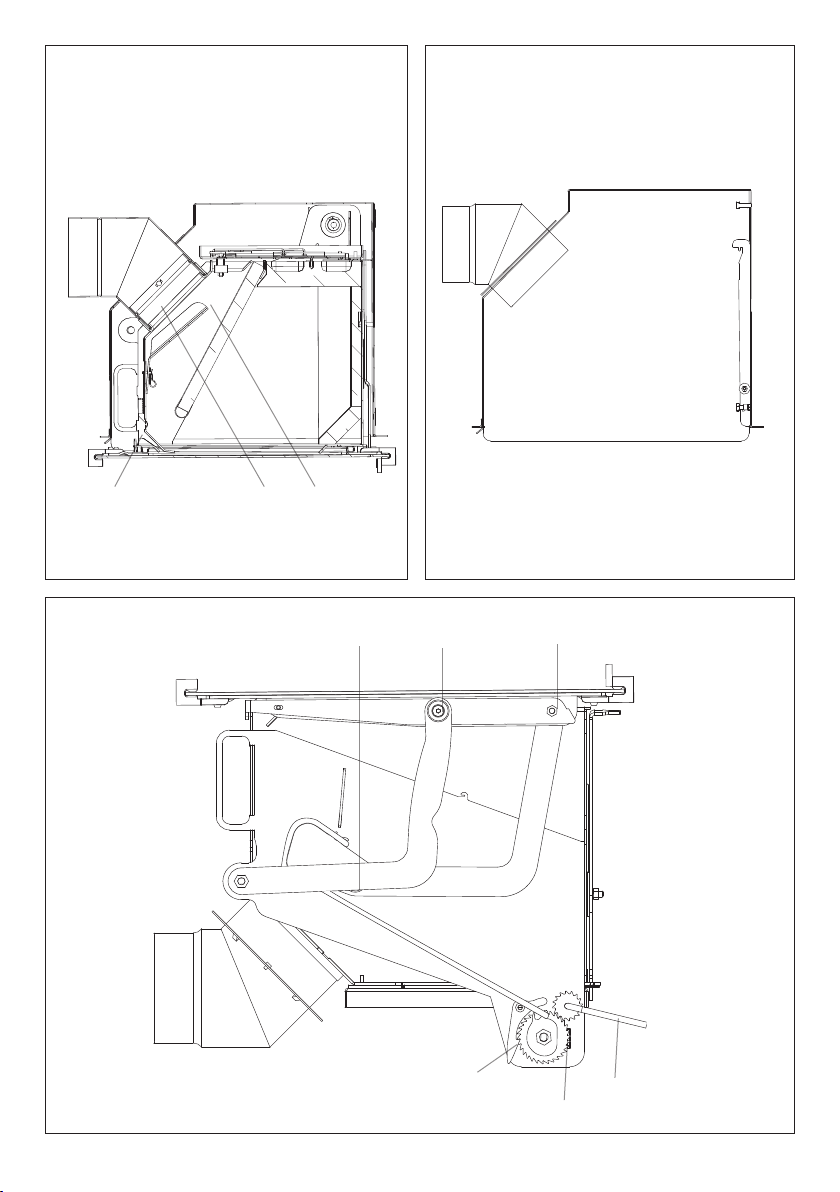

Model Weight Height Width Depth

HWAM I30/55 98 kg 53,4cm 73,8 cm 47,0 cm

Floor plate

European, national and local regulations must be observed in terms of the size and thickness of a non-

combustible floor covering the floor in front of the combustion chamber opening. Ask your HWAM

retailer for assistance.The combustion chamber opening is 56.0 cm wide.

Distance to combustible materials

Please refer to local building regulations to determine the size of the fireproof area in front of the fireplace.

The insert must be positioned at least 30 cm above the floor if the floor is made of combustible material.

If there is combustible material around the outer casing,non-combustible insulation (Fire Batts) is required

between the casing and the combustible material.The insulation must be 80 mm thick on both sides of

the casing,120 mm behind the casing and 60 mm thick beneath the bottom of the casing.The requirement

for insulation above the top of the casing is 150 mm.The thermal conductivity of the insulation must be

less than 0.1 W/m x K (as measured at 200 ºC).

Requirements for chimney and smoke pipe

The height of the chimney must ensure sufficient draught and prevent any smoke nuisance.As a general

rule, satisfactory draught conditions are achieved if the chimney is 4 m above the stove and at least 80

cm above the ridge. If the chimney is placed at side walls, the top of the chimney should always be higher

than the ridge or the tallest point of the roof.Always be aware of any national and/or local regulations

applying to thatched roofs and the location of the chimneys.

The woodburning stove requires a minimum draught of 12 Pa (measured at EN 13240 measurement

point). If measured just above the smoke flue socket, the chimney draught must be 18-20 Pa.

The chimney must have a minimum clearing of Ø 150 mm.The chimney must be provided with an eas-

ily accessible cleaning door.The chimney and flue duct must be of flue class T400 and be CE marked.

Furthermore, it must have obtained the classification of G in soot fire testing. The required distance

to combustible material must be complied with in accordance with the brand label.Ask your HWAM

retailer for further information.

Chimney

The chimney is the “engine” of the stove and it is crucial for the functioning of the woodburning stove.

The chimney draft provides a partial vacuum in the stove.This vacuum removes the smoke from the stove,

sucks air through the dampers for the so-called glass pane rinse which keeps the glass free of soot, and

sucks in air through both primary and secondary dampers for the combustion.

The chimney draft is created by the differences in temperature inside and outside the chimney.The higher

the temperature within the chimney,the greater the draft. It is crucial, therefore,that the chimney is warmed

up properly before closing the damper and limiting the combustion in the stove (a brick chimney takes

longer to warm up than a steel chimney).On days where the weather and wind conditions create insufficient

draught inside the chimney, it is even more important to warm up the chimney as quickly as possible.The

trick is to quickly get some flames going. Split the wood into extra fine pieces, use an extra firelighter, etc.

If the stove has not been used for a longer period,it is important to check that the chimney pipe is not blocked.