Content

FCU 5000/-T001

Page 2 / 60

MoWa FCU5000 T001 4609526 en-us 2021-10-11.docx

Content

Content ..........................................................................................................2

General ..........................................................................................................4

Imprint.............................................................................................4

Documentation Representative ......................................................4

Purpose of this manual...................................................................4

Target group of the manual ............................................................5

Target group - Required qualifications / knowledge........................6

Illustrations in the manual...............................................................7

Illustration of the layout ...............................................................7

Representation of procedural instructions...................................8

Representation of warning / general safety information ..............8

Signal words and their meaning in the general safety

information ..................................................................................9

Representation / explanation of pictograms..................................10

Supplementary symbols ...............................................................11

Exclusion of liability / warranty......................................................12

Notes on copyright........................................................................12

Validity of this manual...................................................................12

General Safety Information........................................................................12

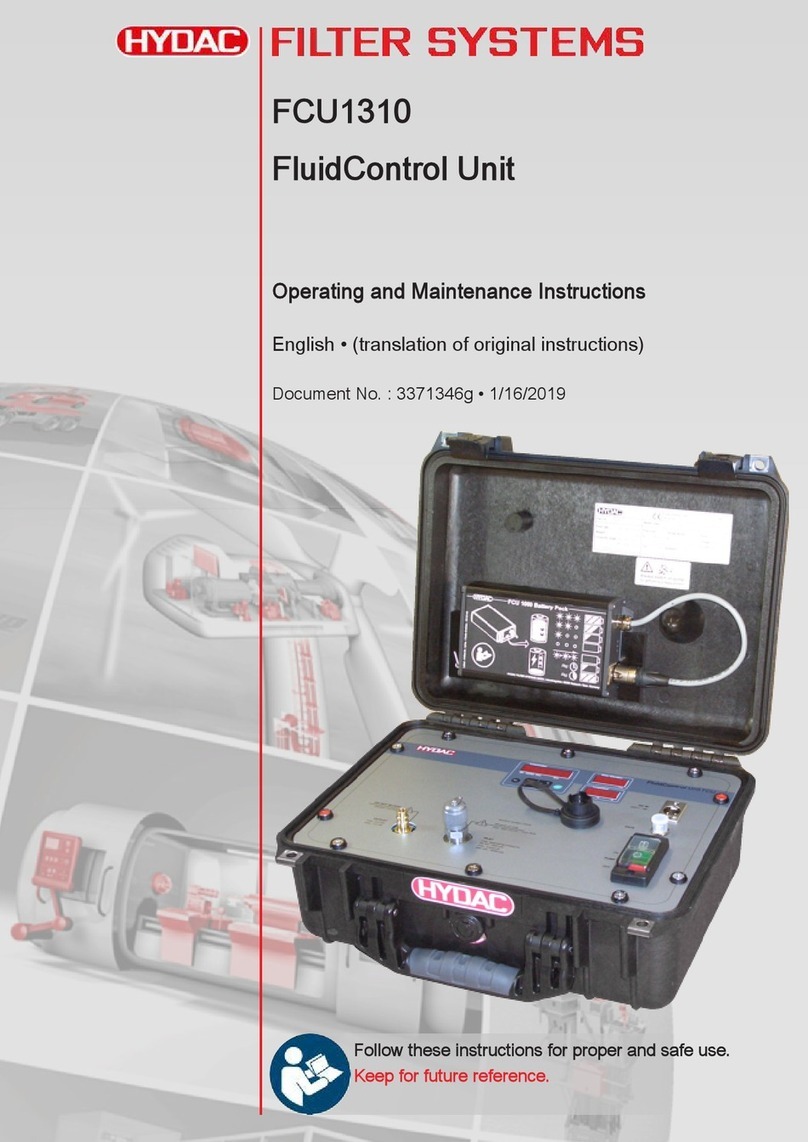

Product overview........................................................................................13

Scope of delivery..........................................................................14

Dimensions...................................................................................15

Connections and components......................................................15

Hydraulic diagram of the sensor unit............................................17

The complete hydraulic circuit of the FCU 5000 is included in the

scope of delivery of the device. ....................................................17

Proper/Designated Use ................................................................18

Hazard warnings...........................................................................19

Improper use or use deviating from intended use.........................20

Technical data..............................................................................21

Name plate...................................................................................21

Model Code...............................................................................23

The model code is created according to the following model

code. .........................................................................................23

Transportation and storage .......................................................................24

Assembly, installation and commissioning .............................................25

Design and placement..................................................................25

Hydraulic installation / assembly...................................................25

Electrical installation / assembly...................................................26