Documentation Representative

FMM-O-M en(us) Page 3 / 32

MoWa FMM-O-M 3874983 en(us) 2013-09-16.doc 2013-09-16

Content

Imprint............................................................................................................2

Documentation Representative ...................................................................2

Preface...........................................................................................................5

Customer service.........................................................................................6

Modifications to the Product ........................................................................6

Warranty ......................................................................................................6

Using the documentation .............................................................................7

Safety Information and Instructions............................................................8

Hazard symbols...........................................................................................8

Signal words and their meaning in the safety information and

instructions ..................................................................................................9

Structure of the safety information and instructions.....................................9

Observe regulatory information .................................................................10

Proper/Designated Use .............................................................................10

Improper Use or Use Deviating from Intended Use ...................................11

Qualifications of personnel / target group ..................................................12

Unpacking the FMM ....................................................................................13

Storing the FMM..........................................................................................14

Decoding the model code label .................................................................14

Checking the scope of delivery .................................................................15

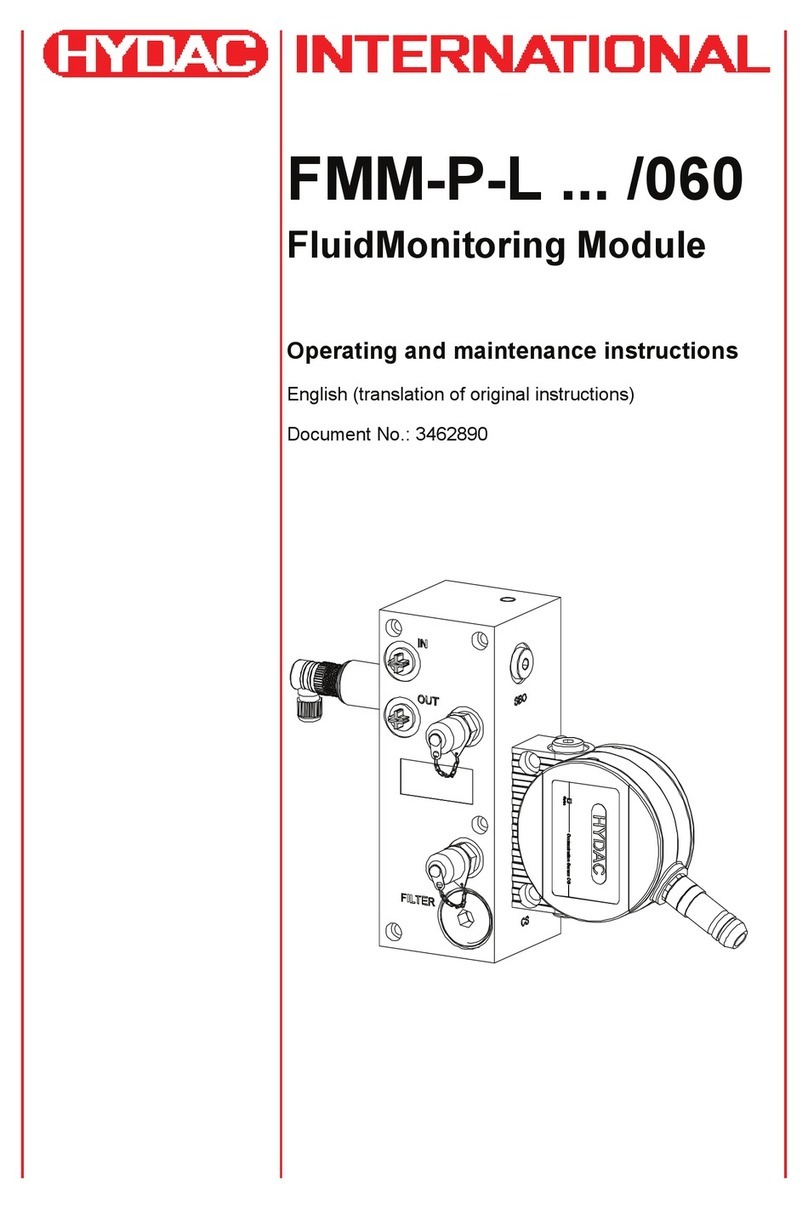

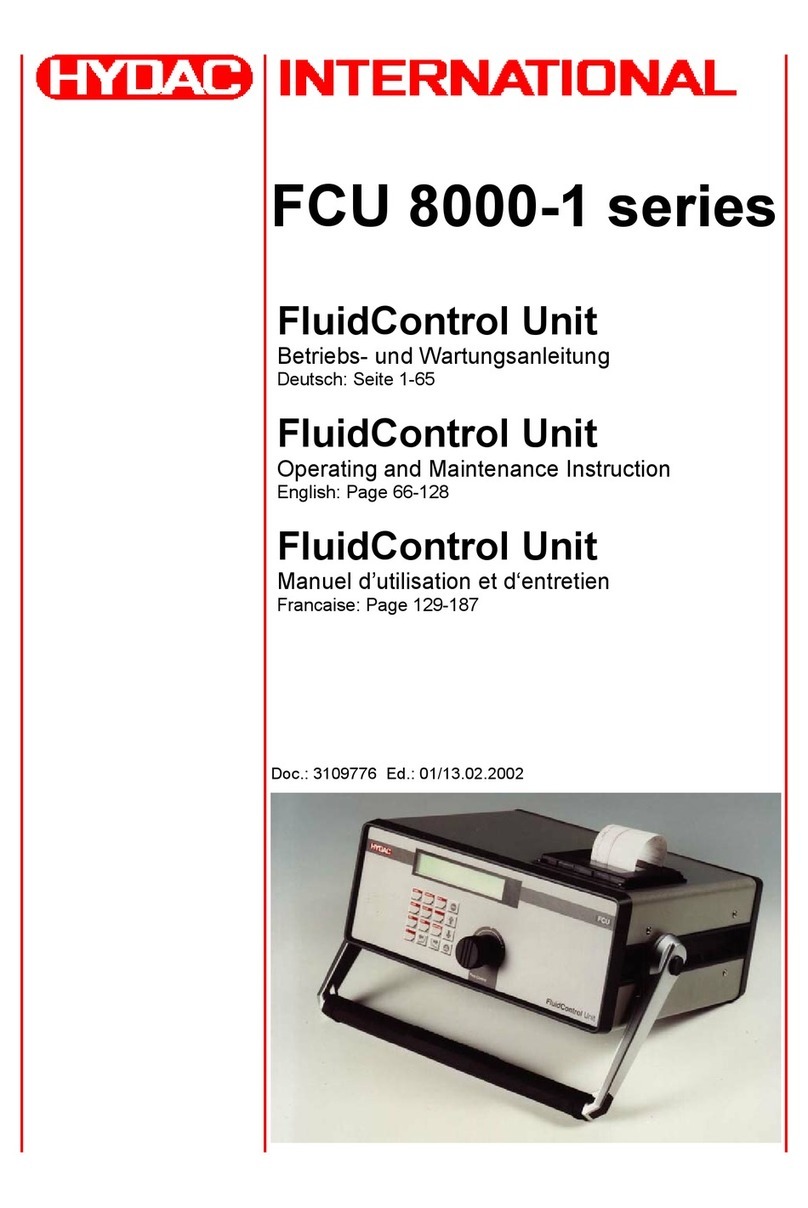

FMM Features..............................................................................................16

Components ..............................................................................................17

Dimensions..................................................................................................18

Hydraulic diagram.......................................................................................18

Attaching the FMMP mechanically ............................................................19

FMM hydraulic installation.........................................................................20

Connecting FMM with the hydraulic system ............................................21

Setting flow rate..........................................................................................22

Error messages / Troubleshooting............................................................23