GENERAL DESCRIPTION

A650 Data Processing System is made up of acombination of several units

connected by cables

.

A650 Basic System must have:

650 Console Unit 1only

655 Power Unit 1only

These units may be installed:

407 Accounting Machine

533 Card Read Punch

537 Card Read Punch

653 Storage Unit 1only

A650 System with magnetic tapes and/or disk storage must have:

650 Console Unit 1only

652 Control Unit 1only

653 Storage Unit 1only

655 Power Unit 1only

727 Magnetic Tape Unit 1to 6

and/or

355 Disk Storage 1to 4

These units may be installed:

407 Accounting Machine

533 Card Read Punch

537 Card Read Punch

838 Inquiry Station

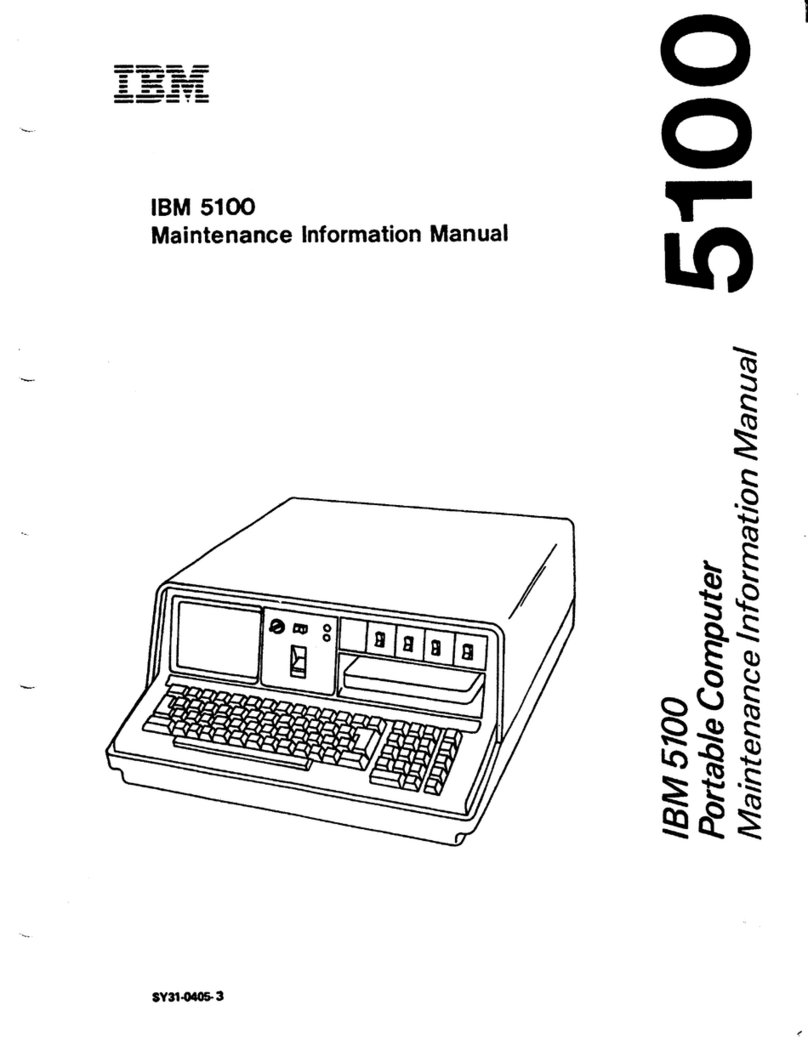

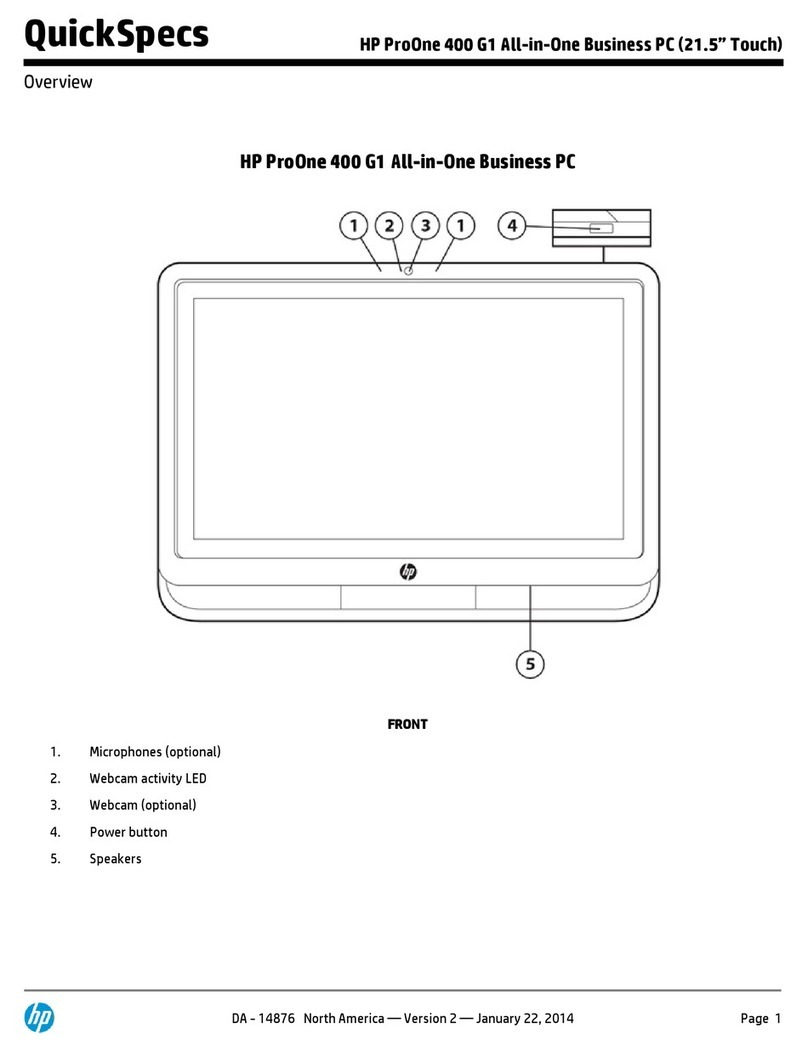

The 650 Console Unit has acontrol console and contains the magnetic drum and

the logical and arithmetic circuits .

The 652 Control Unit has an indicating panel and contains the power supply and

control circuits for the 727 and/or the 355 and 838 units.

The 653 Storage Unit has an indicating panel and may contain immediate access

storage, index registers and automatic floating- decimal arithmetic. This unit

with immediate access storage is anecessary component of atape system, and/or

disk storage system.