3

Thank you for purchasing this Soft & Yogurt Ice Cream Maker from Icetro Corp. Be sure to read this user manual for the

correct usage and maintenance of the product. If you encounter any problem while using the product,

refer to this manual for troubleshooting. Keep this manual in a safe place since it contains the warranty certificate.

The product must be installed by a qualified engineer. Icetro will not be liable for any quality or functionality issue resulting

from using a part or a component other than that authorized or supplied by Icetro or any part or component authorized

or supplied by Icetro but modified in any way.

(Functions or specifications published on the Icetro website or this manual may be changed at the discretion of Icetro

without prior notice.) Be sure to visit http://www.icetro.com for the latest specifications.

Safety Cautions .................................................................................................................................................... 4~7

How to unpack and install the ice cream maker ............................................................................................... 8

How to install ........................................................................................................................................................ 9

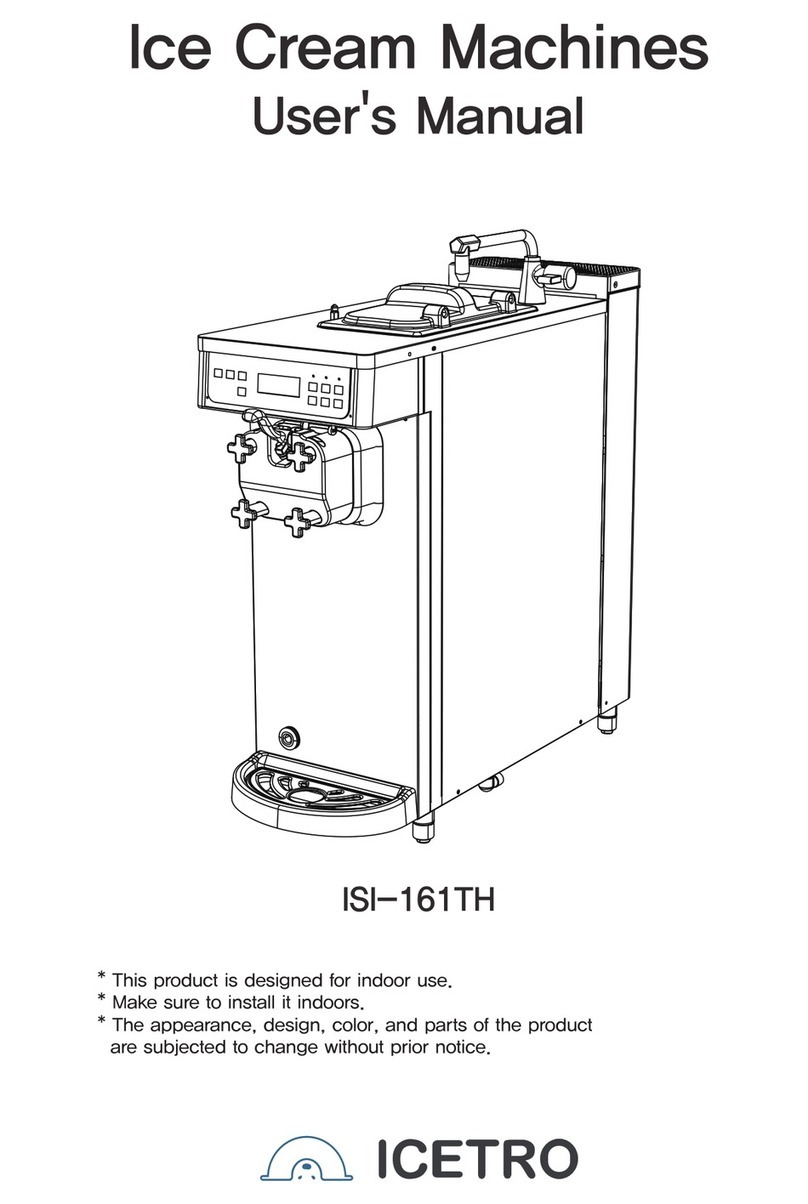

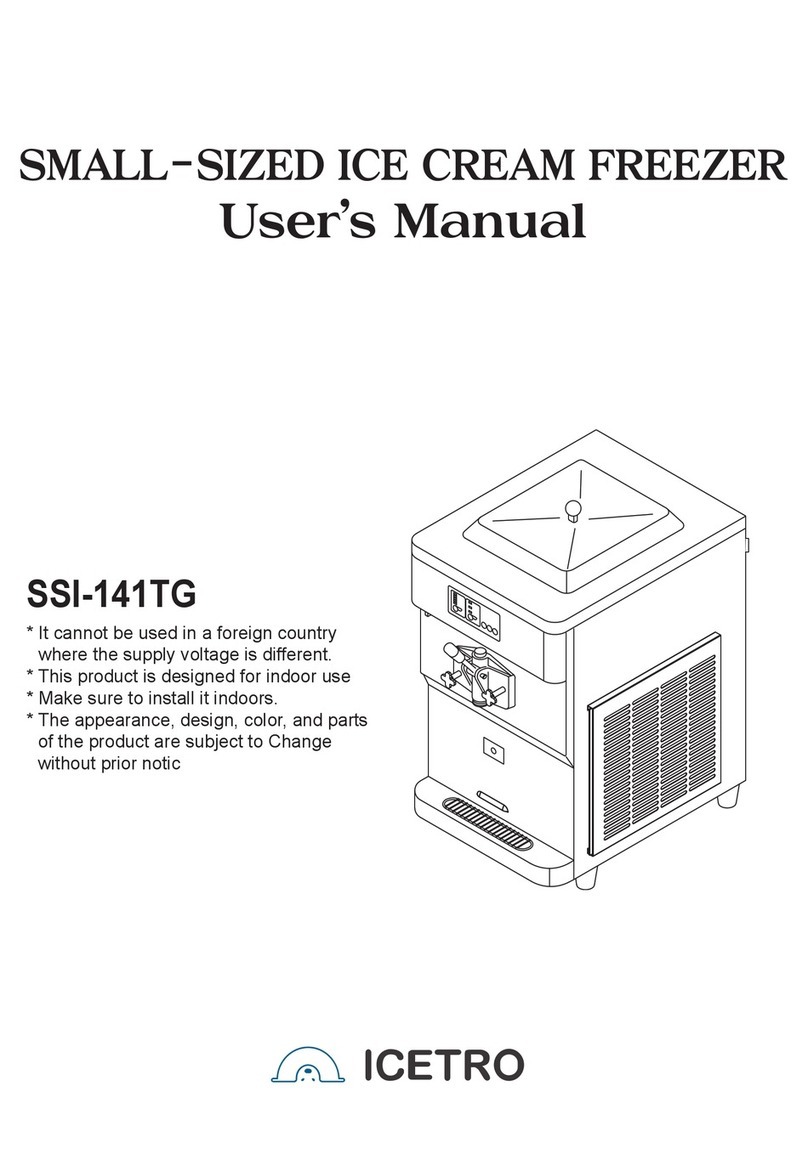

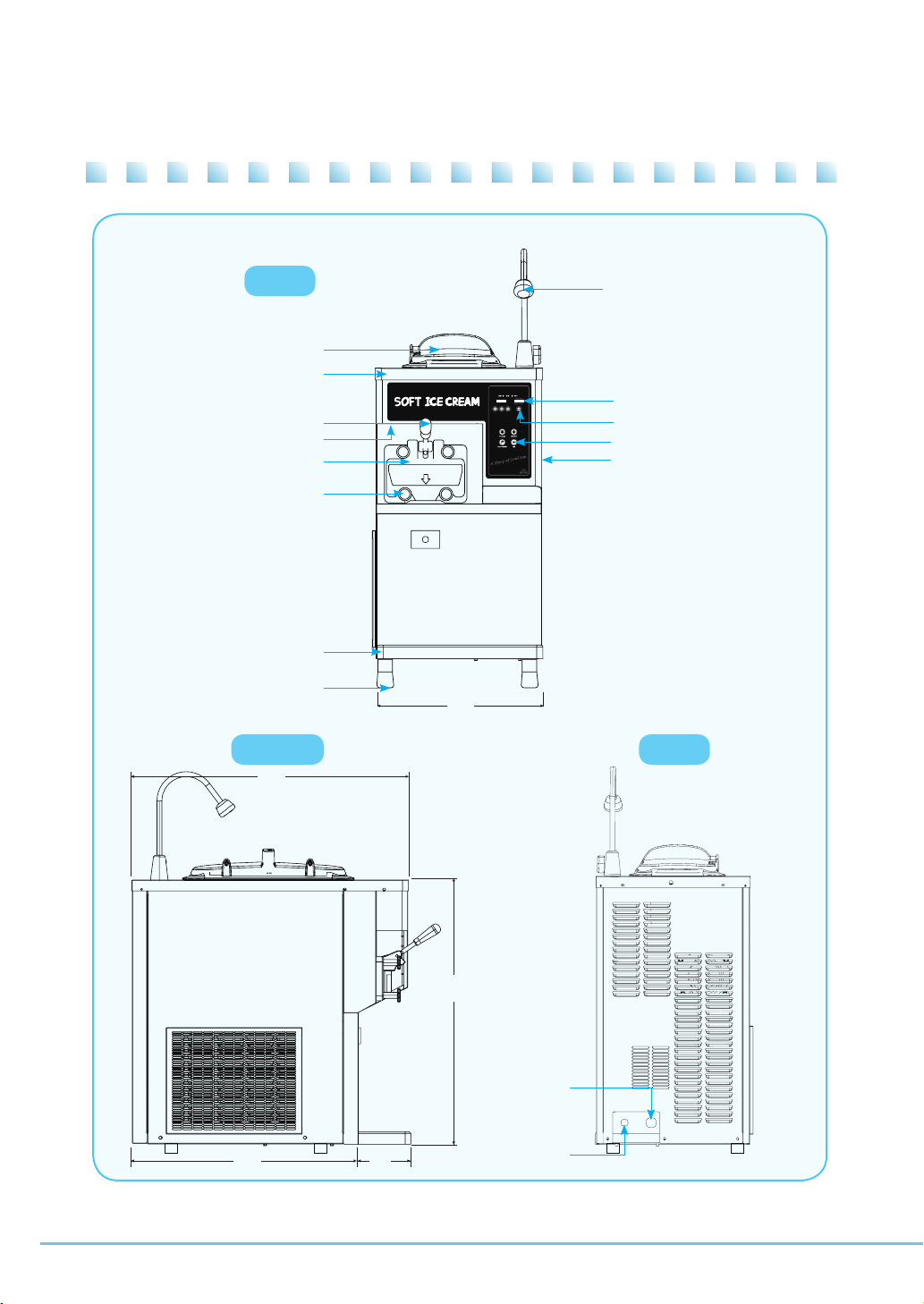

Description of parts and dimensions .................................................................................................................. 10~11

Specifications ....................................................................................................................................................... 12

What to check before using the product ............................................................................................................ 13

Button display description and functions ........................................................................................................... 14

Detailed description of each mode ..................................................................................................................... 15~23

Making ice cream ................................................................................................................................................ 24

Controlling the speed of making ice cream ....................................................................................................... 25

How to adjust the carburetor ............................................................................................................................... 26

How to clean ........................................................................................................................................................ 27~31

Assembling the dasher and dasher cover ......................................................................................................... 32

Before requesting for customer service .............................................................................................................. 33

Replacement cycle of consumable parts ........................................................................................................... 34

Error code type and corrective actions .............................................................................................................. 35

Circuit diagram ..................................................................................................................................................... 36

What to watch out for .......................................................................................................................................... 37

Warranty ............................................................................................................................................................... 38

Contents

Dear customer,