icetro SSI-141TG User manual

Other icetro Ice Cream Maker manuals

icetro

icetro ISI-303SNA User manual

icetro

icetro SSI-143S User manual

icetro

icetro ISI-271THN User manual

icetro

icetro ISI-163TT User manual

icetro

icetro SSI-300T User manual

icetro

icetro ISI-321TA User manual

icetro

icetro ISI-271SHSN User manual

icetro

icetro ISI-271THS User manual

icetro

icetro ISI-273SH3S User manual

icetro

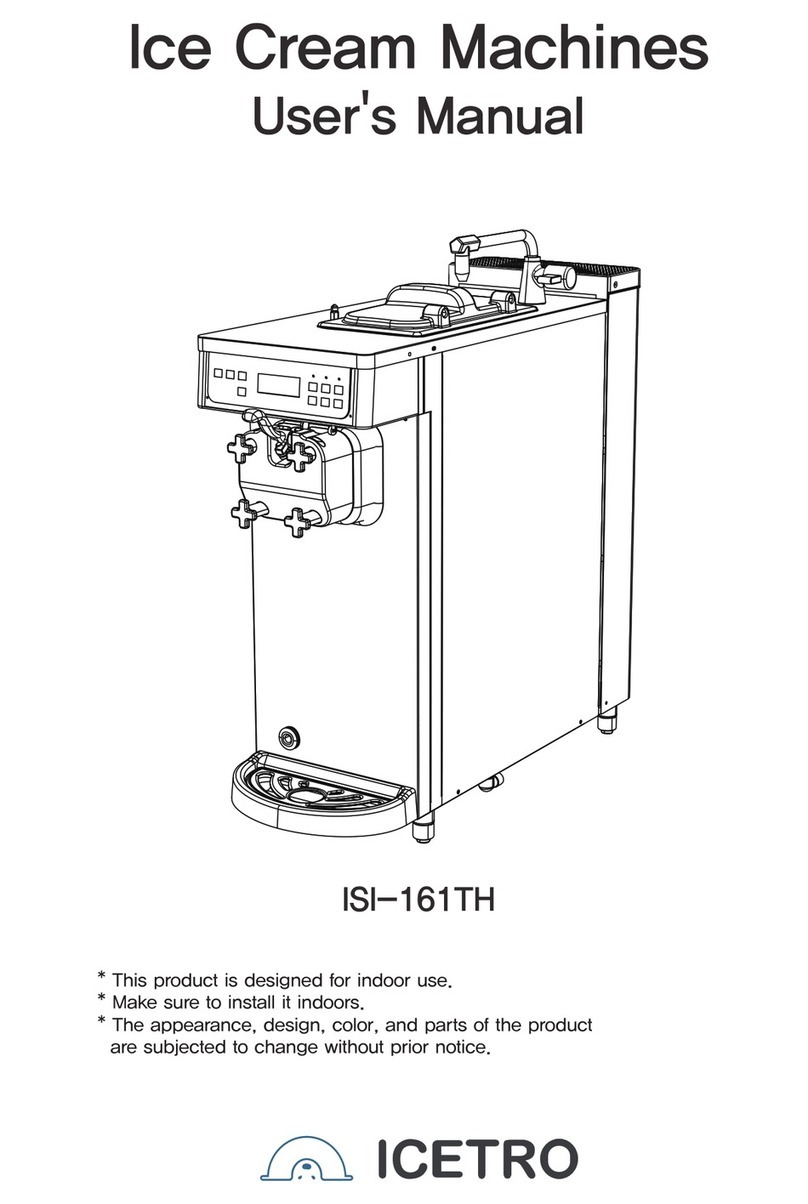

icetro ISI-161TH User manual

Popular Ice Cream Maker manuals by other brands

ICETEAM 1927

ICETEAM 1927 COMPACTA VARIO US Instruction handbook

Coldelite

Coldelite EPS 60 XP Instruction handbook

Coldelite

Coldelite COMPACTA Series Instruction handbook

Italian Gelato

Italian Gelato ICETEAM 1927 STARGEL 5 Instruction handbook

Italian Gelato

Italian Gelato CATTABRIGA MANTEMATIC K20S Instruction handbook

CATTABRIGA

CATTABRIGA EFFE4 B Instruction handbook