4

Cautions for your safety

These are safety related items. So, comply with them at all times!

They are meant to protect the safety of users and prevent property damages.

Please, read the cautionary items carefully for correct use.

Danger

If violated, it can cause death

or severe injury.

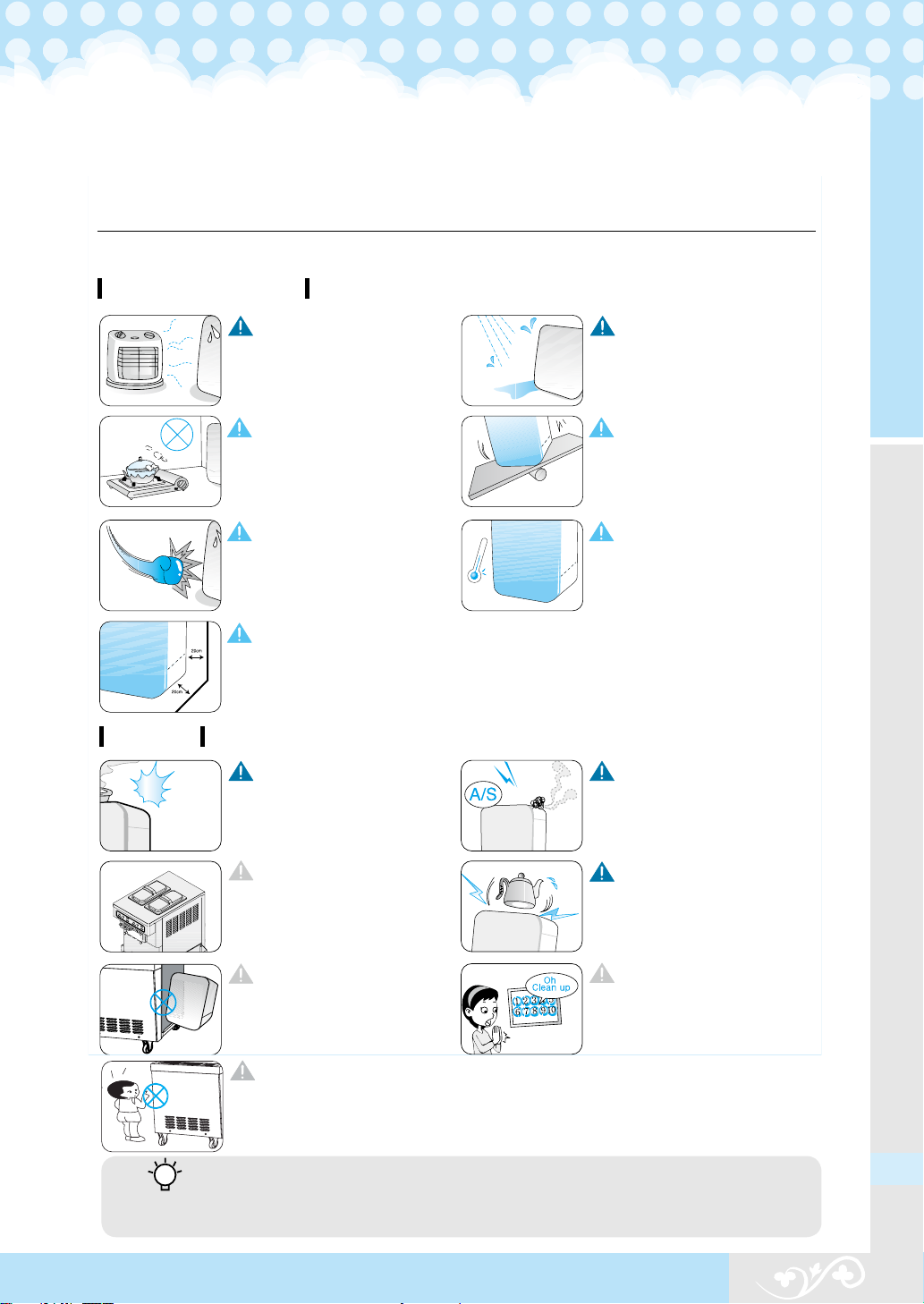

Install it independently with an

earth leakage circuit breaker

with more than 50[A].

It can cause electrical shocks or fire.

Warning

If violated, it can cause sever

physical injury or property

damages.

Caution

If violated, it can cause

slight physical injury or

property damages.

Do not move the product by

pulling on the power cord.

It can cause electrical shocks or fires.

Do not bend the power cord too

much or cause damages or

deformation by pressing it under

a heavy object.

It can cause electrical shocks or fires.

If there is water inside the

power supply, turn off the

earth leakage circuit breaker

and dry it before use.

It can cause electrical shocks or

fires.

Do not touch the earth leakage

circuit breaker with your wet

hands.

It can cause electrical shocks or fires.

Do not turn the power on/off with

the circuit breaker continuously.

It can cause electrical shocks or fires.

When you repair or inspect the

product or replace any parts, turn

off the earth leakage circuit

breaker.

It can cause electrical shocks or fires.

Power supply related items

Do not pull on the power cord.

It can cause electrical shocks or fires.

Do not connect many electrical

products to the earth leakage

circuit breaker. Use it individually.

It can cause fires.

If you want to leave it unused for

a long time, then close the water

supply valve and turn off the

earth leakage circuit breaker.

It can cause electrical shocks or fires.

Do not arbitrarily connect the

power cord or process it for use.

It can cause fires.

If the power cable is damaged,

then do not replace it on your

own. Call the service center for

cable replacement.

It can cause electrical shocks or fires.

Use a power cable larger than

4mm9.

The outer box for the product

should be grounded.

It can cause electrical shocks or fires.