2

Contents

1 Preliminary note���������������������������������������������������������������������������������������������������3

1�1 Symbols used ������������������������������������������������������������������������������������������������3

2 Safety instructions �����������������������������������������������������������������������������������������������4

3 Functions and features ����������������������������������������������������������������������������������������5

4 Function���������������������������������������������������������������������������������������������������������������6

4�1 Processing of the measured signals��������������������������������������������������������������6

4�2 Switching function������������������������������������������������������������������������������������������6

4�3 Diagnostic function ����������������������������������������������������������������������������������������7

4�4 Differential pressure measurement����������������������������������������������������������������7

5 Mounting��������������������������������������������������������������������������������������������������������������8

5�1 Mounting accessories������������������������������������������������������������������������������������8

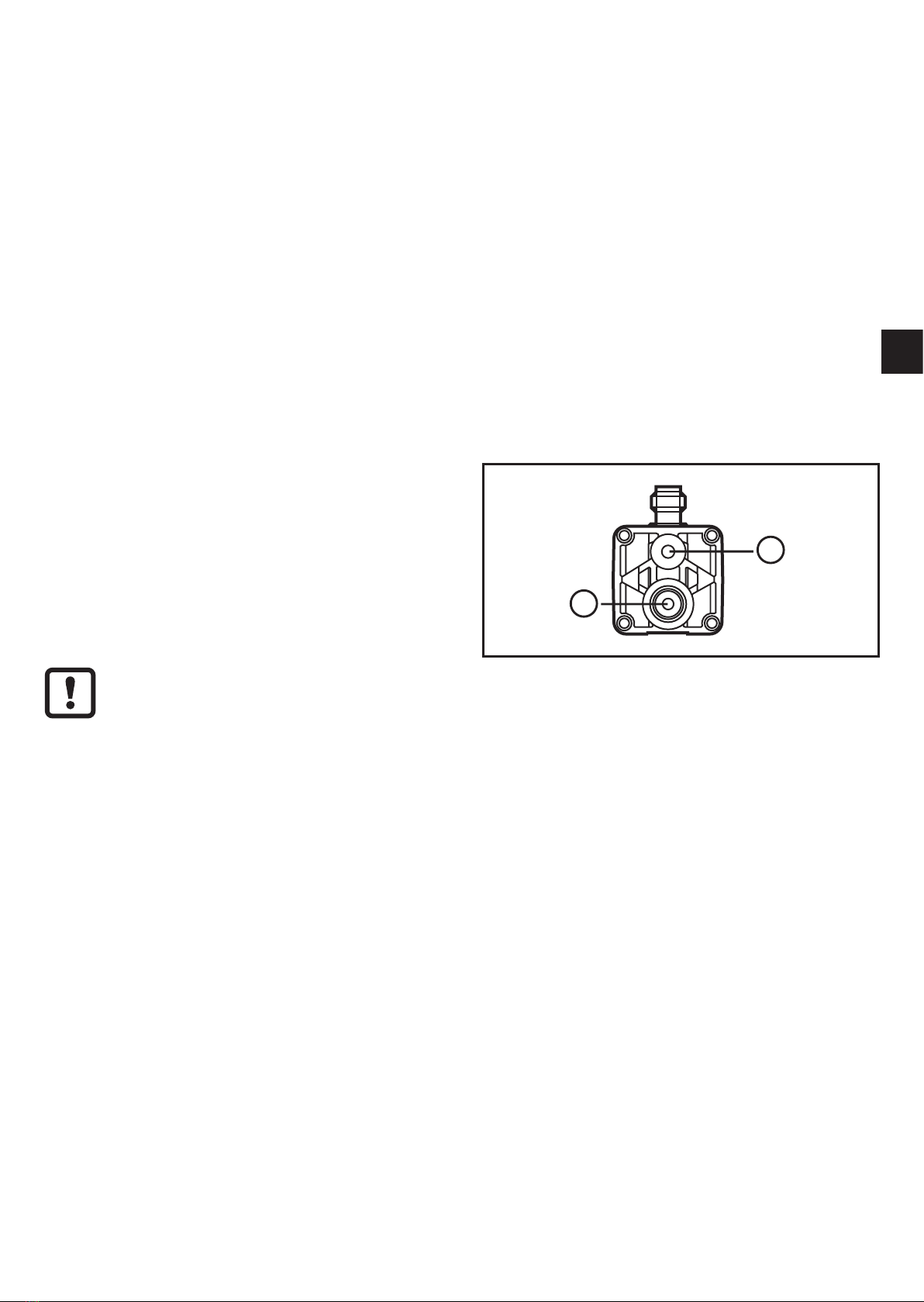

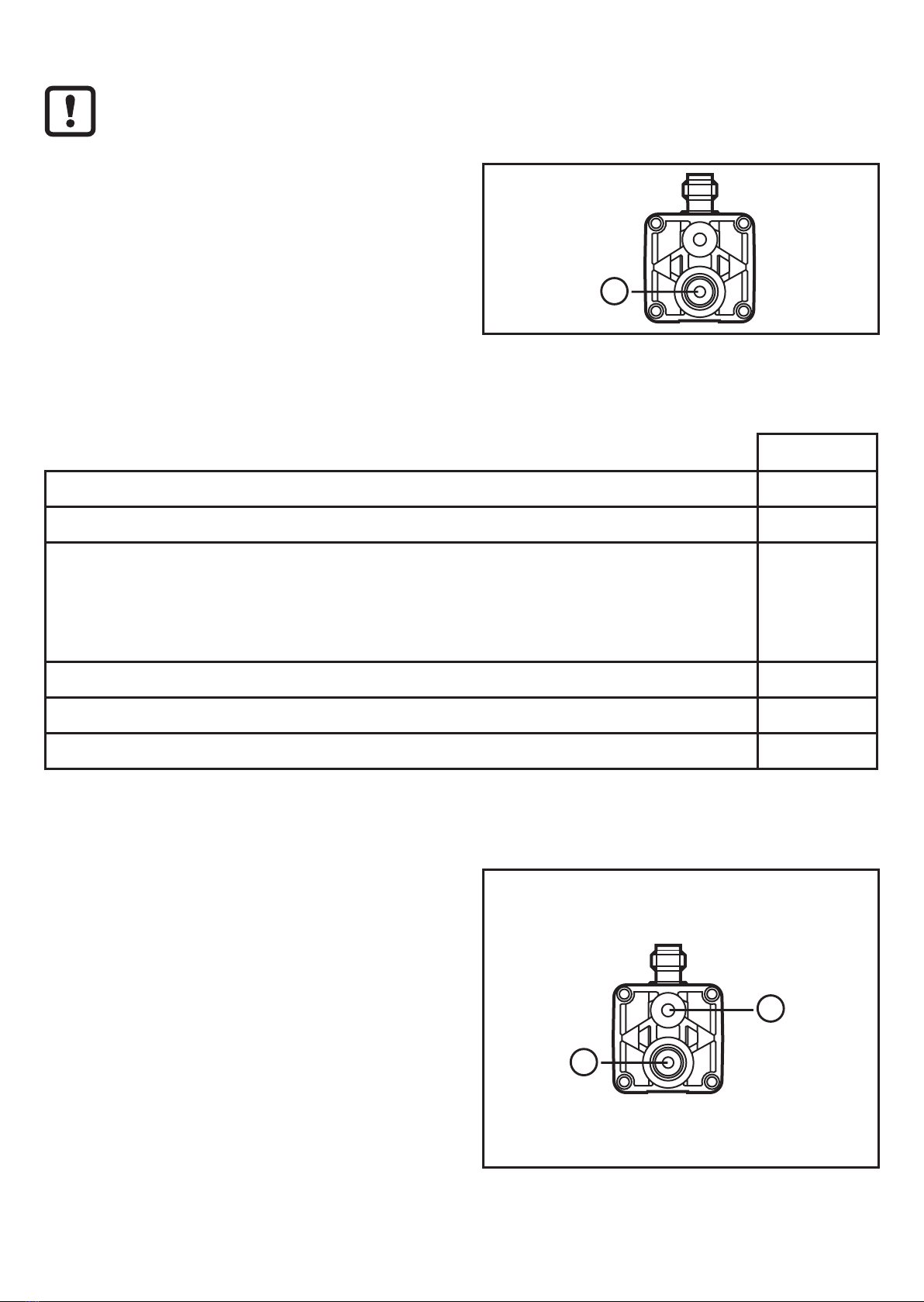

5�2 Pressure connections for differential pressure

measurement�������������������������������������������������������������������������������������������������8

5�3 DIN rail mounting�������������������������������������������������������������������������������������������9

5�4 Rear panel mounting �������������������������������������������������������������������������������������9

5�5 Mounting on a pressure-carrying rear panel������������������������������������������������10

5�6 Floor mounting��������������������������������������������������������������������������������������������� 11

5�7 Mounting on a maintenance unit �����������������������������������������������������������������12

6 Electrical connection������������������������������������������������������������������������������������������13

7 Operating and display elements ������������������������������������������������������������������������14

8 Menu������������������������������������������������������������������������������������������������������������������15

8�1 Menu structure���������������������������������������������������������������������������������������������15

8�2 Explanation of the menu������������������������������������������������������������������������������16

9 Parameter setting ����������������������������������������������������������������������������������������������17

9�1 General parameter setting���������������������������������������������������������������������������17

9�2 Setting of the output signals ������������������������������������������������������������������������19

9�2�1 Setting of the unit of measurement for system pressure ��������������������19

9�2�2 Setting of the output function��������������������������������������������������������������19

9�2�3 Setting of the switching limits �������������������������������������������������������������19

9�3 User settings (optional) �������������������������������������������������������������������������������19

9�3�1 Setting of a time delay for the switching signals���������������������������������19

9�3�2 Setting of the output logic for the switching outputs ���������������������������20