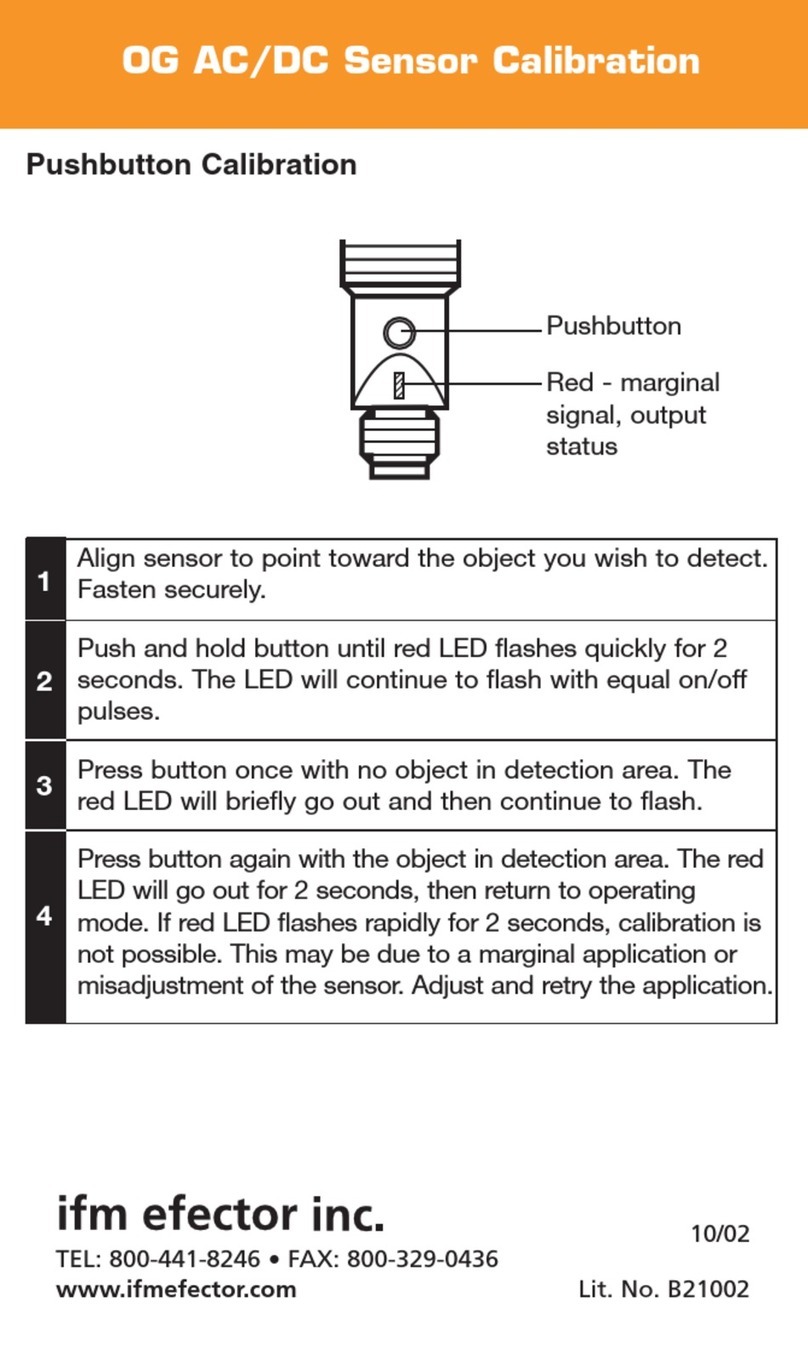

IFM PL205 Series User manual

Other IFM Accessories manuals

IFM

IFM OGH User manual

IFM

IFM Efector500 PY7102 User manual

IFM

IFM OF Series User manual

IFM

IFM EC2061 User manual

IFM

IFM efector 200 O4H5 Series User manual

IFM

IFM LW2720 User manual

IFM

IFM OID20 Series User manual

IFM

IFM SBU3 Series User manual

IFM

IFM Efector 200 Series User manual

IFM

IFM PQ3 Series User manual

IFM

IFM SBG2 Series User manual

IFM

IFM Efector 500 PF2652 User manual

IFM

IFM efector 200 OGS38 Series User manual

IFM

IFM Efector 500 PI30 User manual

IFM

IFM O5D15 Series User manual

IFM

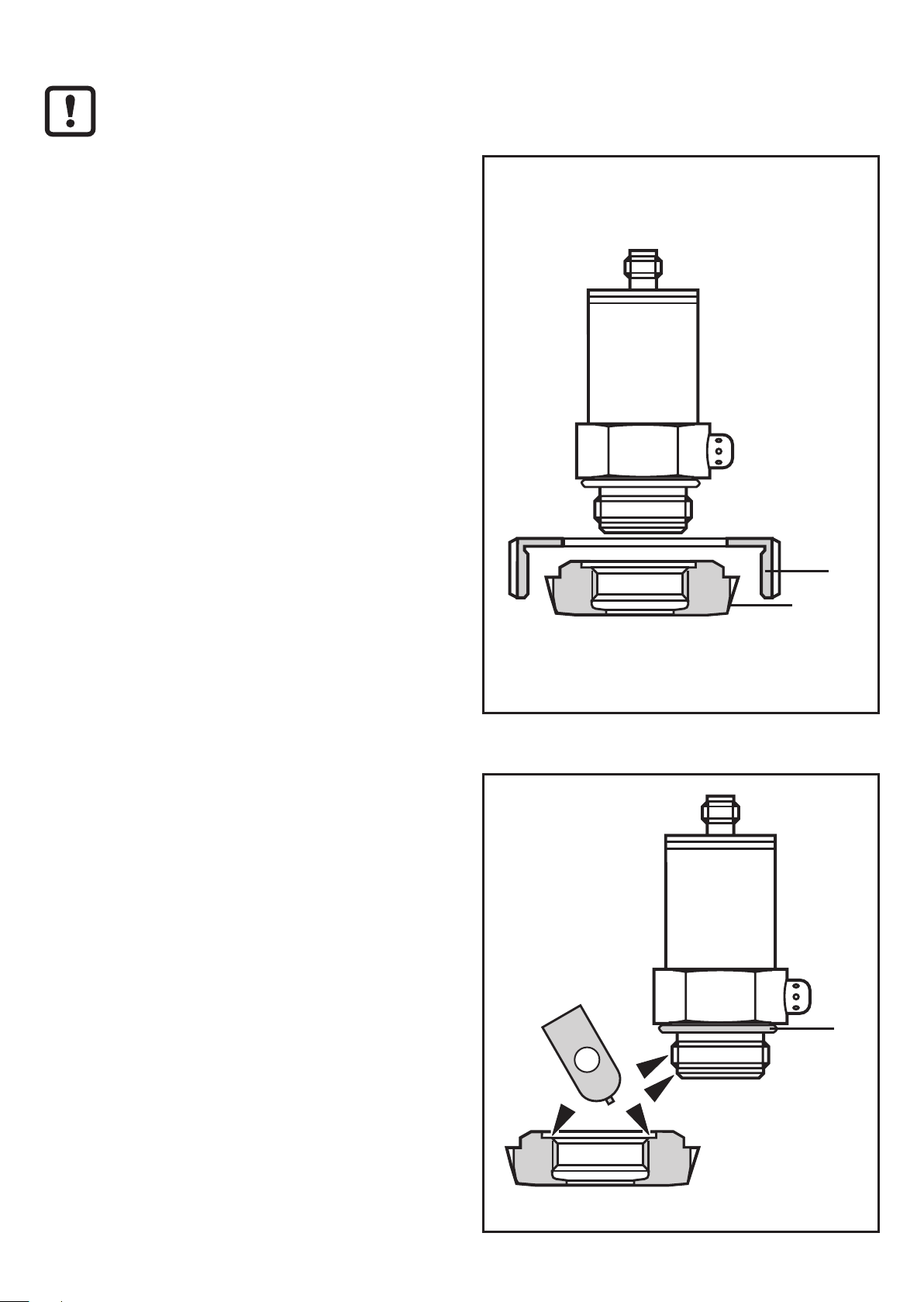

IFM OJ Use and care manual

IFM

IFM SB4 Series User manual

IFM

IFM LDL100 User manual

IFM

IFM KQ10 Series User manual

IFM

IFM VSP003 User manual