18 19

Failure to observe these instructions could re-

sult in damage to the decomposition vessel.

Exploding decomposition vessels present a risk

of serious injury or death. When working with

unknown substances, select very small weighted

samples at the start in order to determine the na-

tural energy.

Normally solid materials in powder form can be

combusted directly. Materials which com-

bust quickly (e.g. benzoic acid) must not

be burnt loose. These materials tend to splash

and there is therefore no guarantee of complete

combustion.

Furthermore, this can damage the inner

wall of the decomposition vessel.

IKA pelleting press C 21 and IKA analytical mill A

11 basic (see Accessories) are available for sample

preparation.

Materials which are dicult to burn (materials

with a high mineral content, low caloric materi-

als) can often only be fully combusted using IKA

acetobutyrate capsules C 10, IKA combustion

bags C 12 or IKA combustible crucible C 14 (see

Accessories). It is also possible to use liquid bur-

ning aids such as paran oil.

Before filling the capsule or the combustion bag

with the substance to be determined, weigh

them to calculate the extra external energy ad-

ded by the burning aid from the weight and the

calorific value. This must be taken into account

in QExternal2. You should keep the amount of

burning aid used to a minimum.

Most fluid substances can weighed out directly

into the crucible. Highly volatile substances are

poured into combustion capsules (IKA gelatine

capsules C 9 or IKA acetobutyrate capsules C 10,

see Accessories) and combusted together with

the capsules.

The burning aids (e.g. cotton thread) must also

fully combust. If there is any unburnt residue, the

test must be repeated.

When working with unknown substances, select

very small weighted samples at the start in order

to determine the natural energy. If you are bur-

ning unknown samples, leave the room or keep

your distance from the calorimeter.

After combustion the water produced is collec-

ted and the decomposition vessel is thoroughly

rinsed with distilled water. The water used for

rinsing and the solution produced are combined

and examined for their acidity. If the sulphur con-

tent of the fuel and the nitric acid correction are

known, it is not necessary to analyse the water.

Note: in all the automatic calculations an extra

100 J have already been included for the electric

ignition energy. This value cannot be set.

Materials which are dicult to ignite or combust

are combusted together with a burning aid. The

burning aid is first weighed and then put into

the crucible with the sample. The additional heat

quantity can be determined from the weight of

the burning aid and its known specific calorific

value. You must correct the test result by this heat

quantity.

IKA- combustible crucible C 14 is a combustible

crucible, which can be used instead of a standard

crucible. The combustible crucible burns without

leaving any residue whatsoever. When using a

combustible crucible you do not need an extra

cotton thread. The crucible is placed directly on

the permanent ignition wire in the decompositi-

on vessel and ignited.

The cleanliness of the material used in the com-

bustible crucible prevents chemical contaminati-

on of the sample (no blank values).

Decomposition vessels, in which the combustible

crucible is used, must be fitted with an extra part

(support C 5010.4, see Accessories). The sample

is weighed out into the combustible crucible as

normal. In most cases no additional burning aid

is required because the combustible crucible itself

serves as a burning aid.

Virtually all of the materials to be studied contain

sulphur and nitrogen. Under the conditions in ca-

lorimetric measurements, sulphur and nitrogen

combust to SO2, SO3 and NOx. Together with

the water from combustion and moisture, sulp-

huric and nitric acid as well as heat of solution

are produced. In order to obtain the standard ca-

lorific value, the influence of the heat of solution

on the calorific value is corrected. The calculation

formulae depend on the standard used. These

are not taken into account in the calculation for

C 200. Use IKA's CalWin software for this.

5.3 Information about the sample

FIt is essential that the sample fully combusts

to ensure correct determination of the calorific

value. After each experiment check the crucible

and all the solid residue for signs of incomplete

combustion.

As a rule the weighted sample must be se-

lected in such a way that the temperature

increase during the measurement is below 4 K

and comes close to the temperature increase

of the calibration (max. extra energy: 40,000 J).

The system must be calibrated in every work

mode used.

If a calorimeter is operated with several de-

composition vessels, you will need to deter-

mine the heat capacity of the system for each

decomposition vessel.

Ensure that calibration is carried out under the

same conditions as the subsequent tests. If sub-

stances are used in the decomposition vessel in

combustion tests (e.g. distilled water or solu-

tions), you must use exactly the same amount of

this substance for calibration.

For more detailed information on calibration, ple-

ase see the relevant standards.

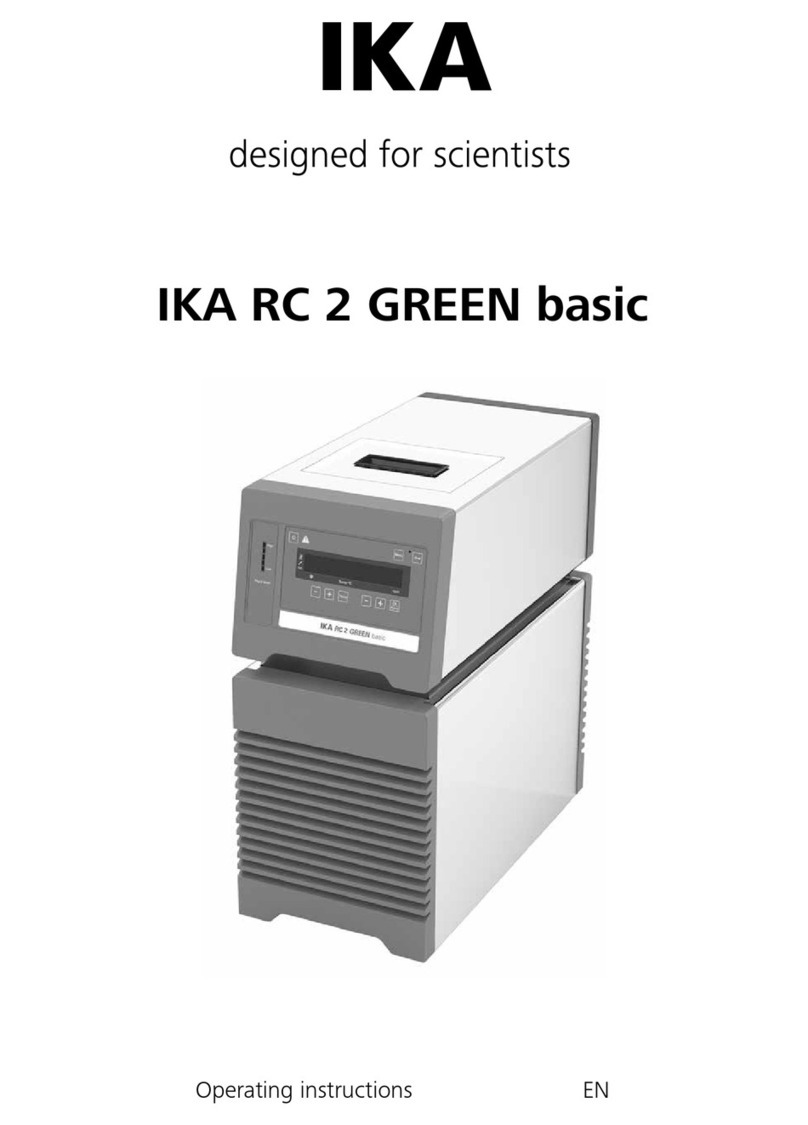

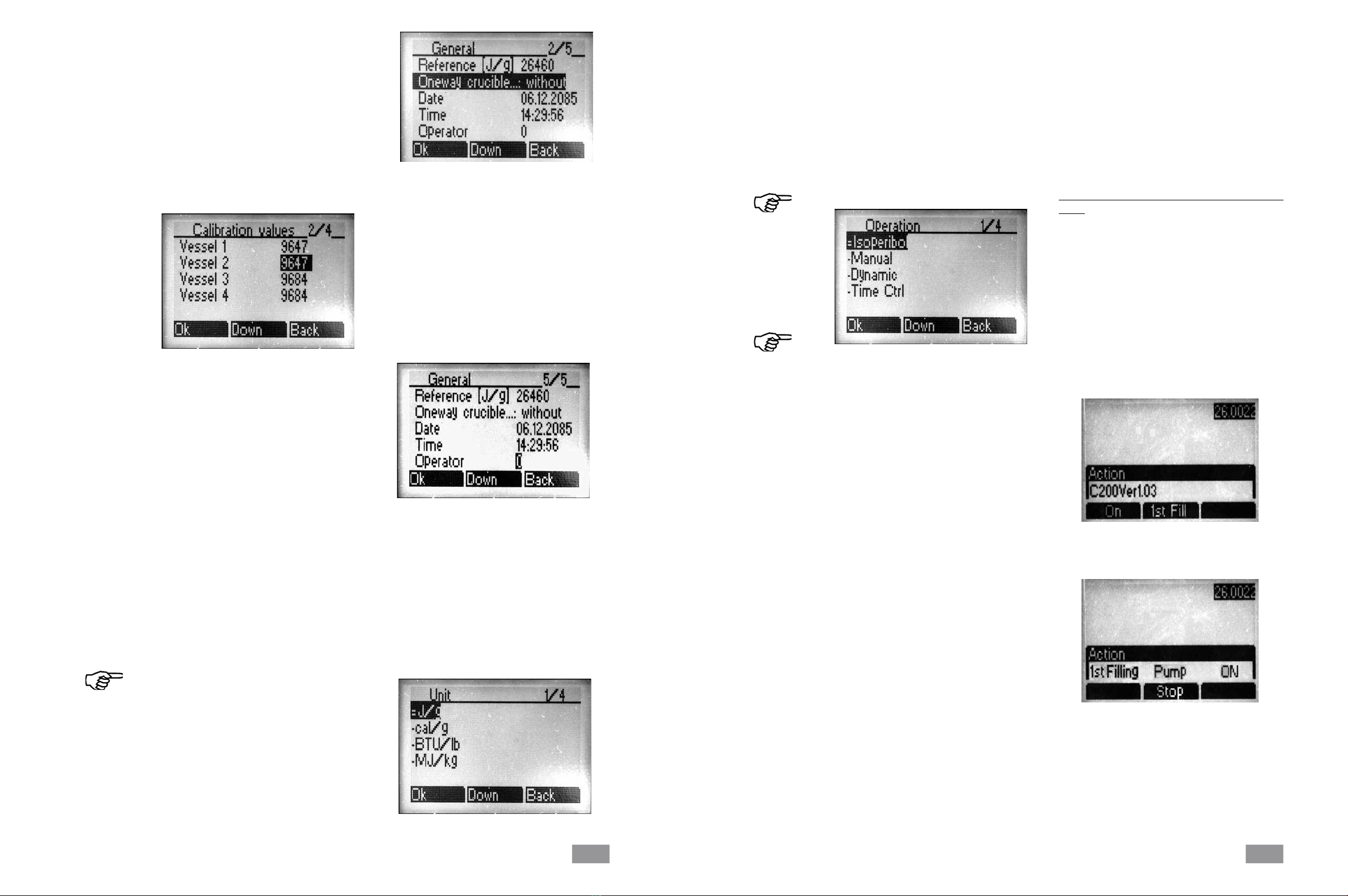

6.1 Decomposition vessel C 5010

If several decomposition vessels are used,

their individual parts must not be interchan-

ged (see Stamping individual parts).

To prolong the life of wearing parts (o-rings,

seals, etc.) we recommend that you always

work with a water trap.

5.4 Calibration

The calorimeter system must be calibrated before

accurate measurements are possible. This is done

by combusting tablets made of certified benzoic

acid (see Accessories) with a known calorific va-

lue. The heat quantity required to raise the tem-

perature of the calorimeter system by one Kelvin

is used to determine the heat capacity of the so-

called "C-value" of the system. For this calculati-

on the formula (1) (see section 5.1) is adapted:

C = (Ho * m + QExt1 + QExt2) / DT (2)

This value is used for determining the following

calorific values.

The heat capacity is determined by the measu-

ring cell and the decomposition vessel. It has a

significant influence on the calorific value to be

calculated and must be redetermined in particular

when using for the first time, after servicing and

when parts are replaced. A monthly control mea-

surement is recommended.

The term "measurements" below refers to both

the measurements to calibrate the calorimeter

system (calibration measurements) and the actual

measurements for determining the calorific value.

The difference lies in the calculation (cf. section

5, formulae (1) and (2)), whereas preparation and

performance are virtually identical.

Exact measurements are only possible when the

individual test steps are carried out carefully.

You must therefore follow the exact proce-

dure described in section 1 "For your safe-

ty” and in the following sections

Please also see section 5 "Calorimetric measure-

ments”.

Failure to observe these instructions could re-

sult in damage to the decomposition vessel.

Damaged decomposition vessels could crack!

Follow the operating instructions for the de-

composition vessel!

Preparing and performing measurements

Union nut

Oxygen valve

Cover

Crucible

Electric

ignition

contact

Ignition

wire

Crucible

holder