)RU\RXUVDIHW\

IKA-WERKE C 7000 Ver. 07 09.07

3DJH

When handling combustion samples, combustion residues and auxiliary materials,

the appropriate safety requirements must be observed. The following are examples

of substances that may cause dangers:

–corrosive

–easily flammable

–capable of exploding

–contaminated with bacteria

–toxic

When working with oxygen, observe the appropriate requirements.

Danger warning: As a compressed gas, oxygen promotes combustion, supports

combustion intensively and may react violently with combustible substances.

'RQRWXVHDQ\RLORUJUHDVH

Keep all gas lines and screw connections that carry oxygen free from grease.

Observe the accident prevention requirements applicable to the activity and the

work station.

Close the main valve on the oxygen supply when work is complete.

Only carry out maintenance work when the system is depressurised.

When using crucibles made of stainless steel, their condition should be carefully

checked after every experiment.

A reduction in the thickness of the material may cause the crucible to burn and may

damage the decomposition vessel. For reasons of safety, crucibles must not be

used any more after a maximum of 25 combustion procedures.

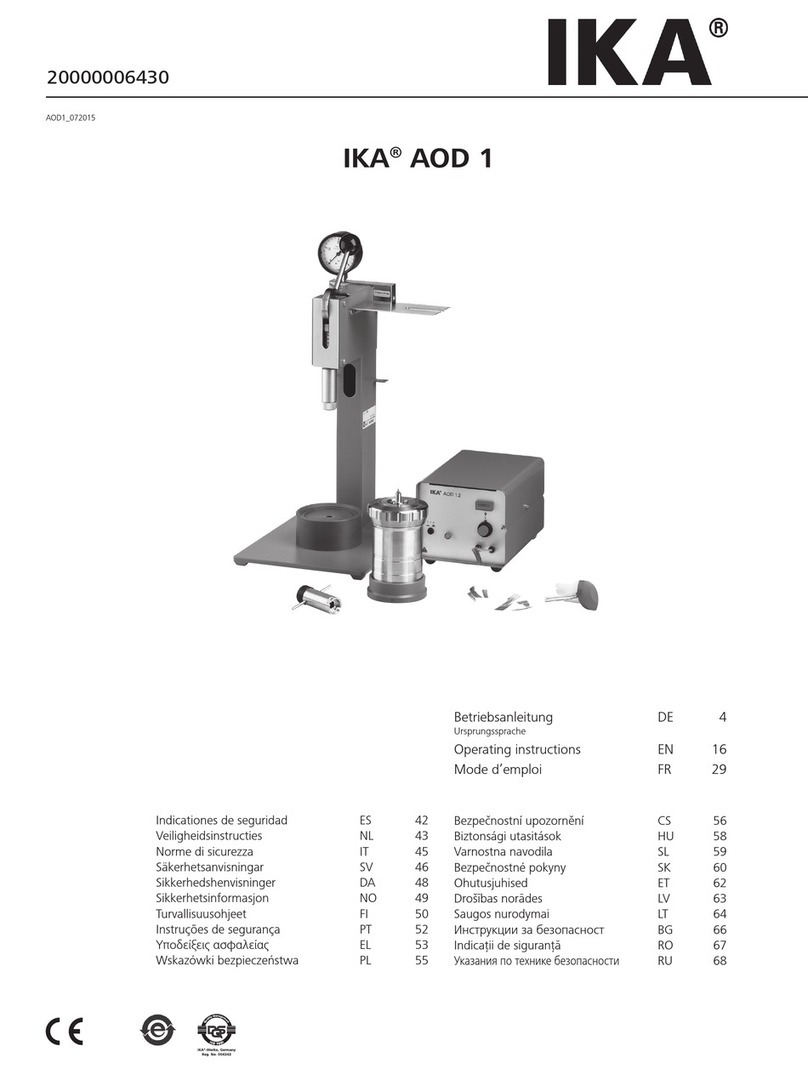

The decomposition vessel C 7010 and C 7012 are manufactured in accordance with

the regulation for pressure vessels 97/ 23/ EC. This can be recognized from the &(

V\PERO with the identifying number of the testing station named. The decomposition

vessel is a pressure device of Category III. The decomposition vessel has been

subjected to an EC prototype test. The CE declaration of conformity represents our

guarantee to you that this decomposition vessel complies with the pressure device

described in the EC prototype test certificate. The decomposition vessel has been

subjected to a pressure test at a test pressure of EDU and a leak test with oxy-

gen at 30 bar.

Decomposition vessels are H[SHULPHQWDXWRFODYHV and must be tested by a SUR

IHVVLRQDOO\WUDLQHGSHUVRQ each time before they are used.

An individual application is understood here to mean a series of experiments that

are performed under roughly the same conditions in terms of pressure and tem-

perature Experiment autoclaves must be operated in special chambers (C 7000).

The decomposition vessel must be subject to repeated tests (internal tests and

pressure tests) by a person with professional training. The intervals between tests

must be determined by the operator based on experience, operating manner and

the material used in the decomposition vessel.

7KHGHFODUDWLRQRIFRQIRUPLW\ORVHVLWVYDOLGLW\LIPHFKDQLFDOPRGLILFDWLRQVDUH

PDGHWRWKHH[SHULPHQWDXWRFODYHVRULIVWDELOLW\FDQQRORQJHUEHJXDUDQWHHG

DVDUHVXOWRIKHDY\FRUURVLRQIRUH[DPSOHKROHVHDWHQLQLWE\KDORJHQV

The WKUHDGLQJ on the body of the decomposition vessel and cap screw in particular

are subject to a high level of mechanical stress and must therefore be monitored

regularly for ZHDUDQGWHDU.

The condition of the seals must be checked for functionality must be ensured by

means of a test for leaks (please observe the Operating Instructions for the decom-

position vessel).

Pressure tests and service tasks on the decomposition vessel must only be per-

formed by persons with professional training.

2[\JHQ

PDGHRIVWDLQ

OHVVVWHHO

WKHGHFRPSRVL

WLRQYHVVHO

5HSHDWHGWHVWV

SRVH

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com