8 9

Safety instructions

/// General information

›

Read the operating instructions completely before starting up and follow the safety

instructions.

› Keep the operating instructions in a place where it can be accessed by everyone�

› Ensure that only trained staff work with the device�

› Follow the safety instructions, guidelines, occupational health and safety and accident

prevention regulations�

› The device must only be used in a technically perfect condition�

!Notice!

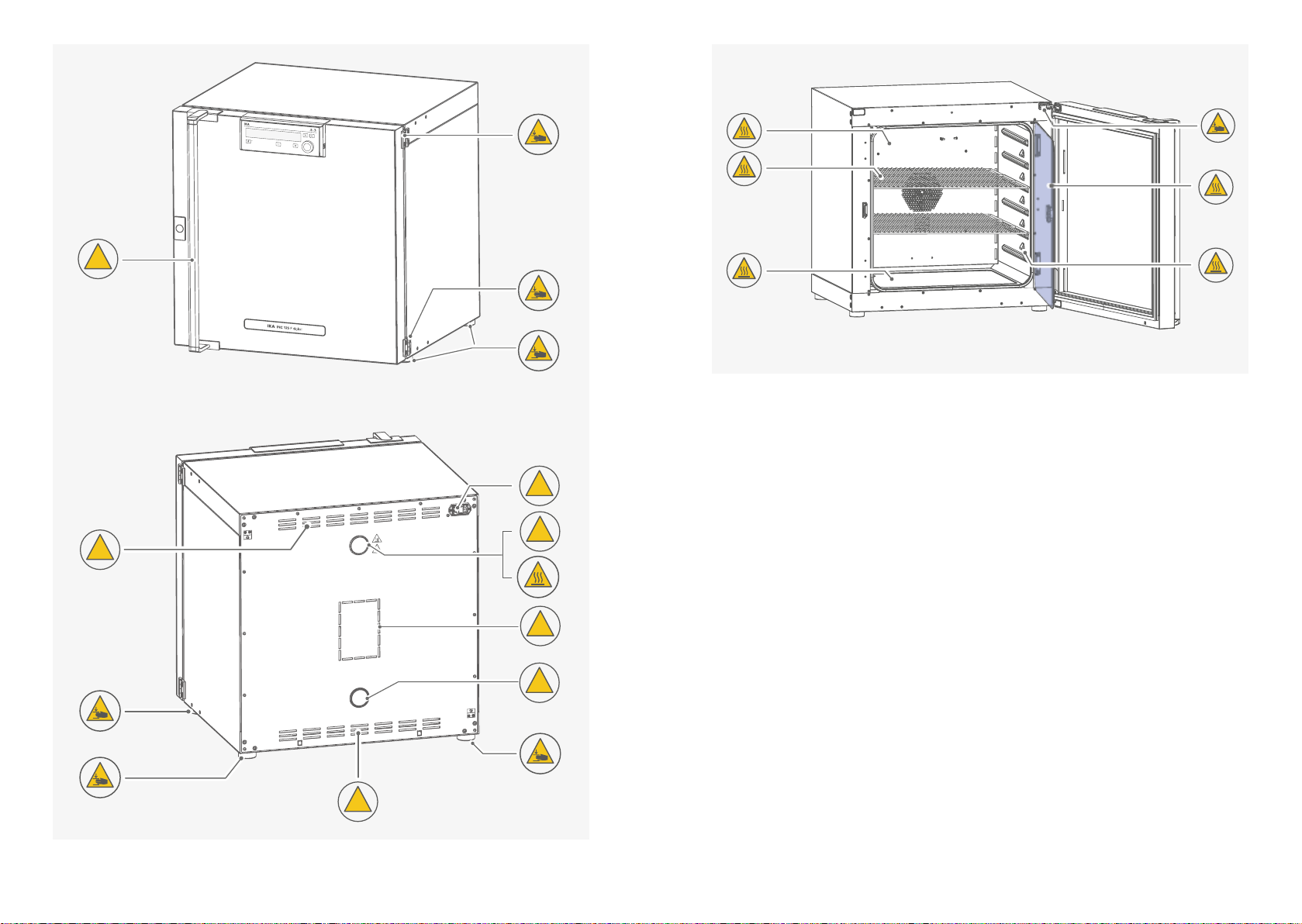

› Pay attention to the marked sites in Fig� 1 and Fig� 2�

!

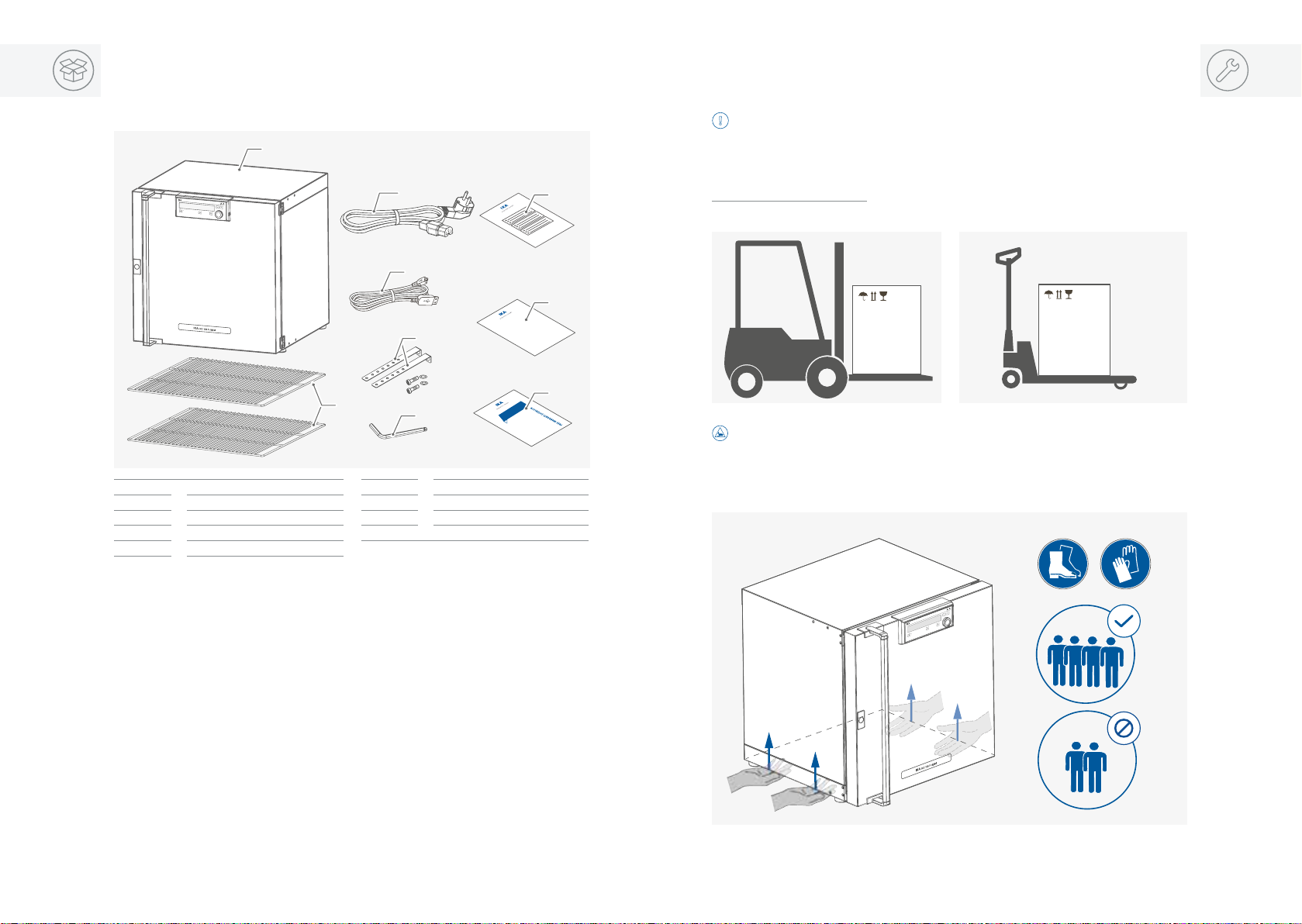

/// Transportation / Device setup

Danger!

› Beware of the high dead weight of the device when transporting�

Caution!

› Ensure that your fingers do not get crushed when setting down the device�

Caution!

› The power switch of the device must be accessed immediately, directly and without risk at

any time� If access to the power switch cannot be ensured, an additional emergency stop

switch that can be easily accessed must be installed in the work area�

/// Working with the device

Danger!

› Do not use the device in explosive atmospheres, it is not EX-protected�

› To avoid body injury and property damage, observe the relevant safety and accident

prevention measures when processing hazardous materials�

Warning!

› Only process samples that will not react dangerously to the extra energy produced through

processing� This also applies to any extra energy produced in other ways, e�g� through light

irradiation�

› Do not start up the device if:

- it is damaged

- cable is damaged�

Warning!

› Risks may also be posed by biological or microbiological substances�

› Observe the national regulations for handling these substances, the biological security level

of your laboratory, the material safety data sheets and the manufacture's application notes�

›

For complete instructions on handling of germs or biological material in risk group II or higher,

please refer to the "Laboratory Biosafety Manual" (source: World Health Organization)�

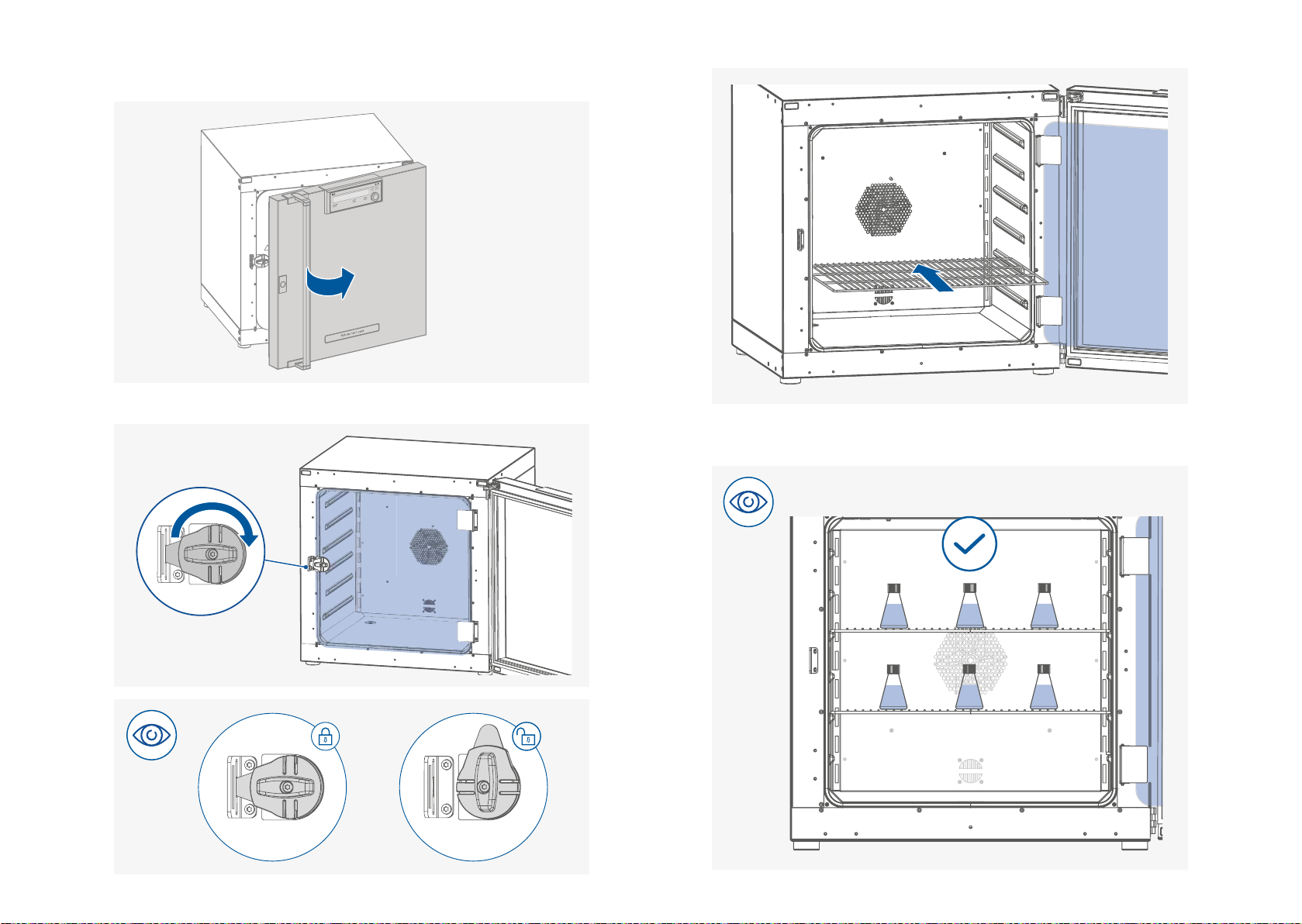

Caution!

› There is a crushing risk when opening or closing the door� Keep your hands away from

squeezing edges�

Caution!

› The area around the air outlet nozzle can get very hot at high operating temperatures�

› The inner chamber, the glass door, the glass door handle, and the door gasket may be-

come hot during operation� Do not touch these parts during operation�

› Risk of burns caused by vapour or hot surface� Pay attention to the residual heat after

switching off the device�

Caution!

›

Media may only be processed or heated with this device in safe operation without monitoring

if their flash point lies above the set safety temperature limit� The set safety temperature limit

must be at least 25°C below the flash point of the medium in use (EN 61010-2)�

› The device must have cooled down before loading / unloading�

› Heavy loads can lead to tilting of the device� Observe loading recommendations for the

shelves�

› Do not move any loaded racks�

/// General Symbols

Position number

A–––

Correct / Result!

Shows the correct execution or the result of an action step�

Wrong!

Shows the incorrect execution of an action step�

Note!

Displays action steps that require particular attention to detail�

Closed lock

Indicates the status of “locked”�

Open lock

Indicates the status of “Unlocked”�

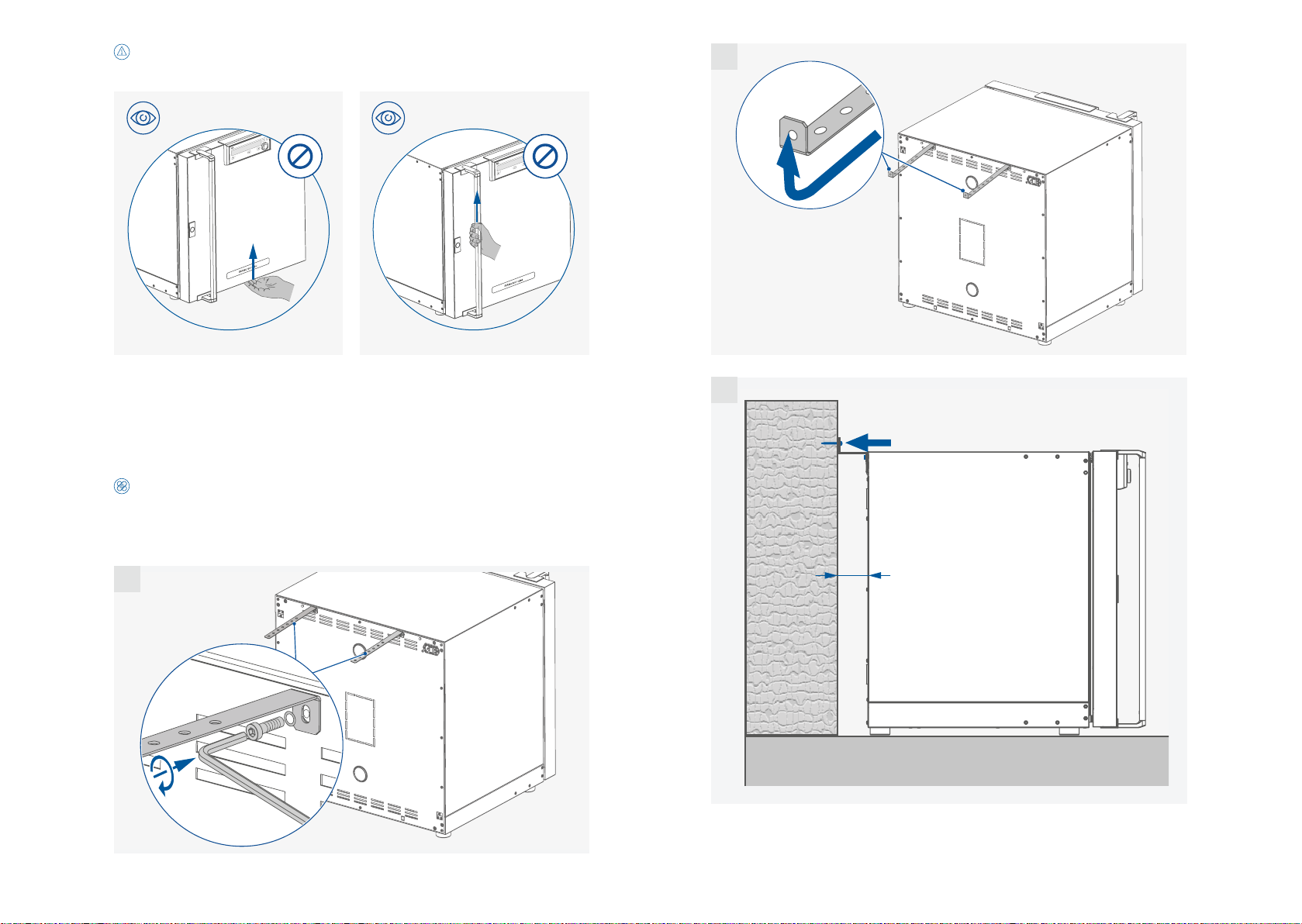

!Notice!

› Set up the device in a spacious area on an even, stable, clean, non-slip, dry and fireproof

surface�

› The feet of the device must be clean and undamaged�

›

Ensure the anti-tilt bracket is properly fixed, in particular when the device is stacked�

›

Make sure that the ventilation slots are not blocked at back of the device�

›

Observe the minimum distances: between devices and wall min� 150 mm�