7

OPERATION

1. First loosen the fascia, then adjust the angle of the grinding blade and tighten.

2. Adjustment of the center axle

a) Rotate the center axle towards the grinding blade when grinding small saw blades and oth-

erwise away from the grinding blade.

b) Push the center axle to the right.

c) Install a new saw blade, rotate the wheel and decide the position of the grinding surface of

saw teeth.

d) Rotate the rotation table to ensure correct grinding angle of saw teeth.

e) Rotate the rotation table in order to ensure correct processing angle of the grinding blade.

The cross-angle between the grinding surface and work surface is about 5°.

3. Adjustment of the positioning assembly

Adjust the saw blade to optimal grinding conditions, rotate the positioning frame and fascia, ad-

just the positioning pin to a better position of saw teeth and leave a gap of grinding quantity.

Then tighten the screw.

4. Adjust the center axle to the same gap of grinding quantity to the right.

5. After all parts are tightened, the saw blade can be sharpened supported with hand.

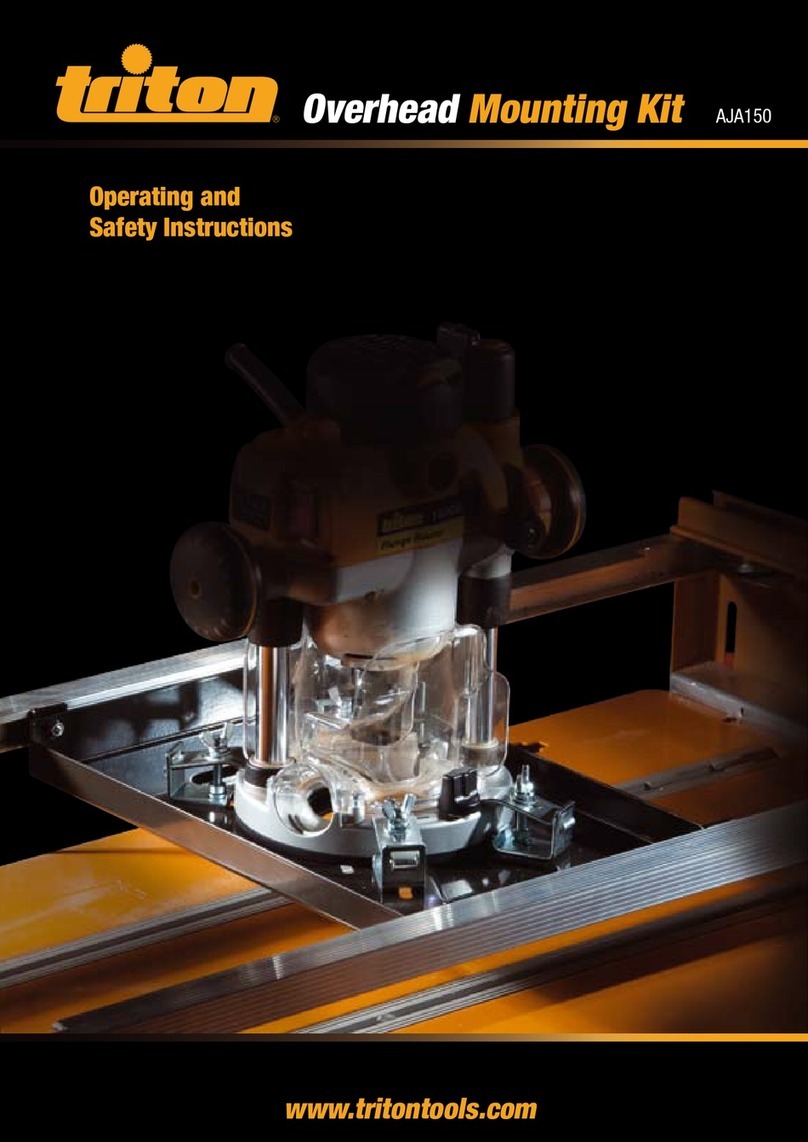

slip board

rotation table

graduation

center axle

slip block

table

limit screw

grinding blade

positioning board

positioning pin

fascia