AEG A18MT User manual

Other AEG Power Tools manuals

AEG

AEG HG 560 D User manual

AEG

AEG VSS 260 User manual

AEG

AEG MFE 1500 User manual

AEG

AEG HEAVY DUTY AG 1000-125 EK User manual

AEG

AEG WS 22-180 User manual

AEG

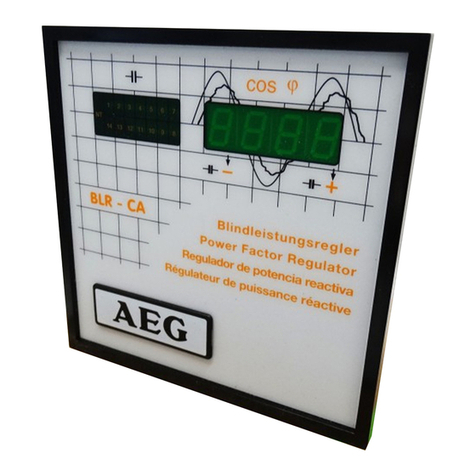

AEG BLR-CA Installation and operation manual

AEG

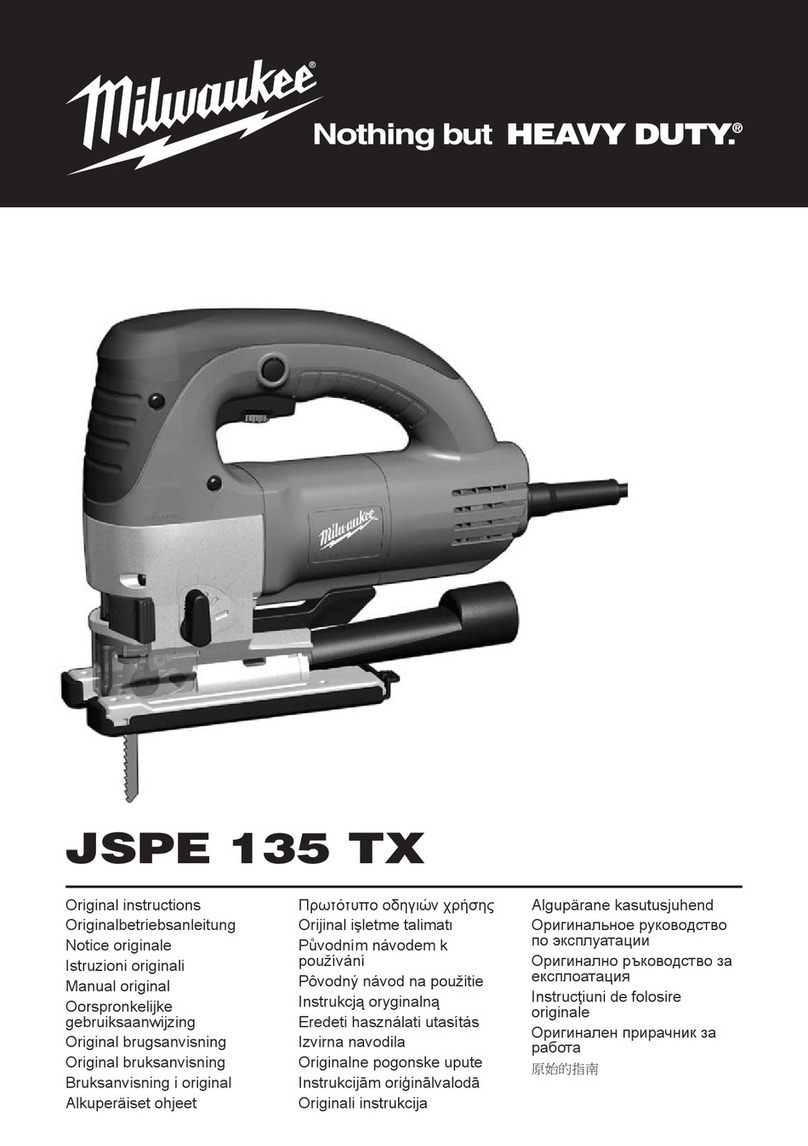

AEG JSPE 135 TX User manual

AEG

AEG 412950 User manual

AEG

AEG BSB 18CBL User manual

AEG

AEG BKP18C600 User manual