Inficon WHISPER User manual

Other Inficon Security Sensor manuals

Inficon

Inficon ELT3000 PLUS Quick guide

Inficon

Inficon RC1000 Series Quick guide

Inficon

Inficon ULTRATEST UL3000 Fab Quick guide

Inficon

Inficon Sensistor ISH2000 HySpeed User manual

Inficon

Inficon Southern Cross IRwin User manual

Inficon

Inficon TEK-Mate User manual

Inficon

Inficon TEK-Mate User manual

Inficon

Inficon UL6000 Fab Quick guide

Inficon

Inficon D-TEK Stratus User manual

Inficon

Inficon D-TEK Stratus User manual

Inficon

Inficon D-TEK CO2 User manual

Inficon

Inficon HLD6000 User manual

Inficon

Inficon D-TEK Stratus 724-202-G Series User manual

Inficon

Inficon IRwin User manual

Inficon

Inficon IRwin User manual

Inficon

Inficon Ecotec E3000 User manual

Inficon

Inficon ELT3000 Quick guide

Inficon

Inficon XL3000flex Manual

Inficon

Inficon D-TEK 3 User manual

Inficon

Inficon Sensistor XRS9012 User manual

Popular Security Sensor manuals by other brands

System Sensor

System Sensor AFD Accuflow Installation and maintenance instructions

EXTOL Craft

EXTOL Craft 97270 user manual

Edwards

Edwards SIGA2-HRS Installation and operation

Buckingham

Buckingham 21402 Attachment instructions

Martec

Martec Sentinel MLXSP524WS quick start guide

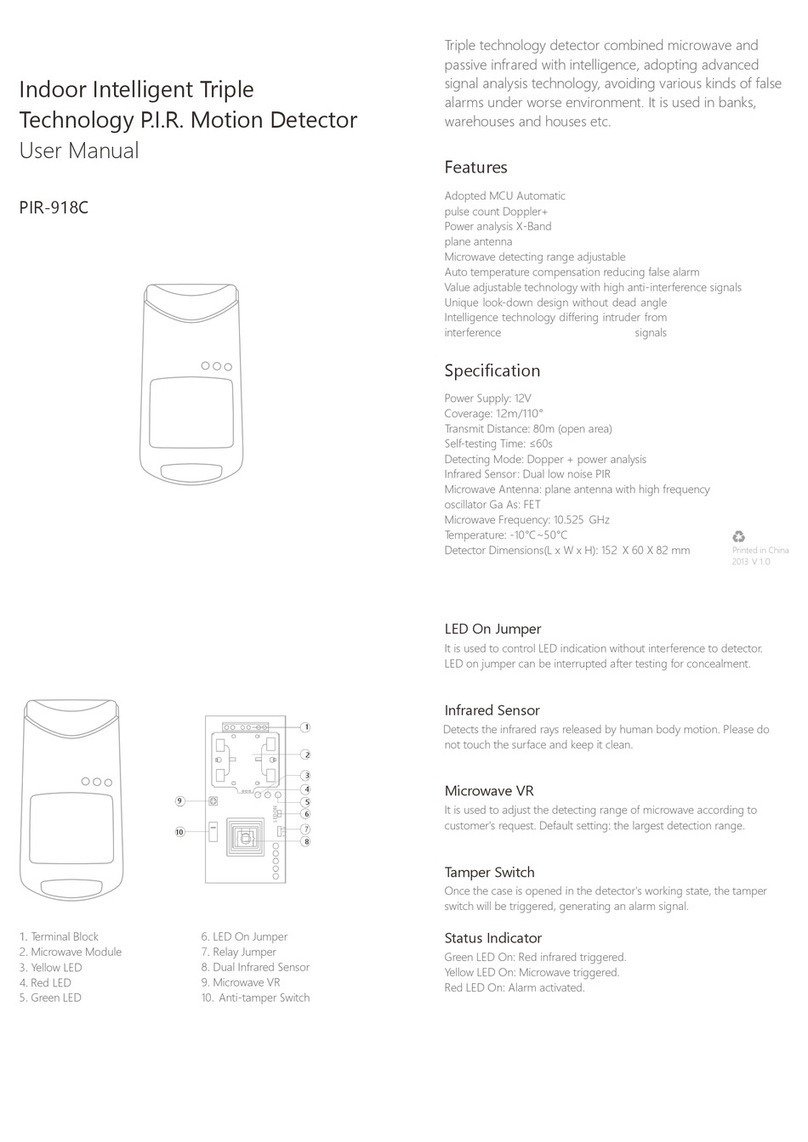

Chuango

Chuango PIR-918C user manual