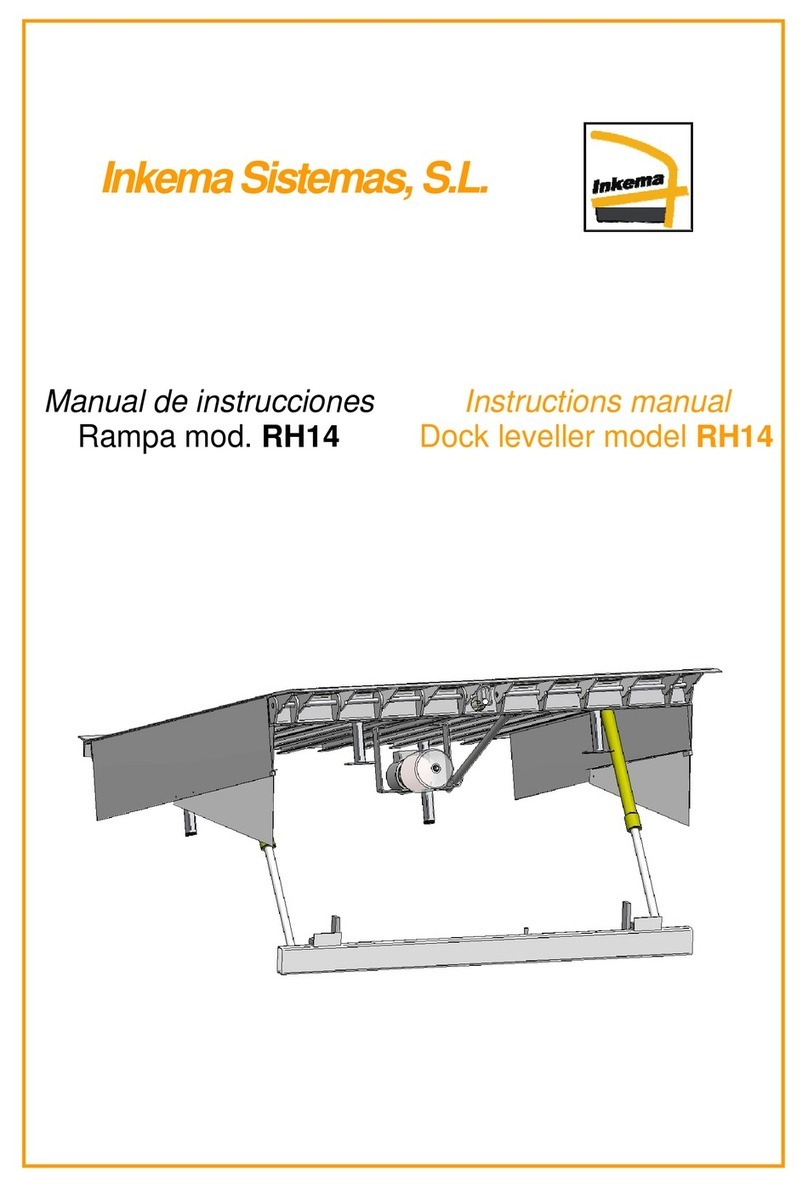

Instructions manual RH14 Inkema

Contents

01 –Introduction........................................................................................................................................ 3

02 –Technical specifications................................................................................................................... 4

02.01 –Usage conditions and limits .................................................................................................................4

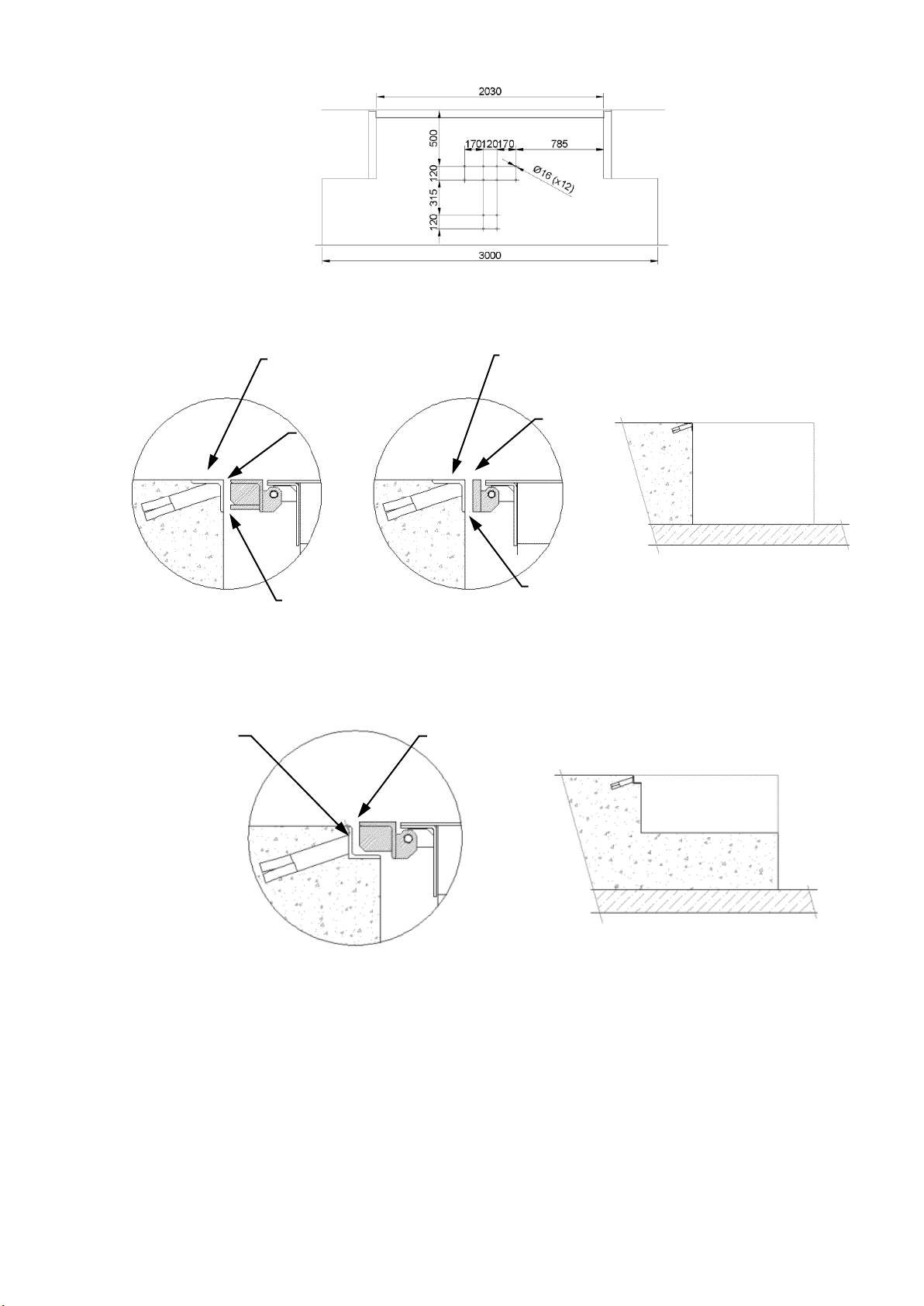

02.02 –Installation in pit with rear elevation cylinder........................................................................................ 4

02.03 –Installation in Pit with front Cylinder.....................................................................................................6

02.04 –Platform ...............................................................................................................................................7

02.05 –Lip........................................................................................................................................................7

02.06 –Inferior structure...................................................................................................................................7

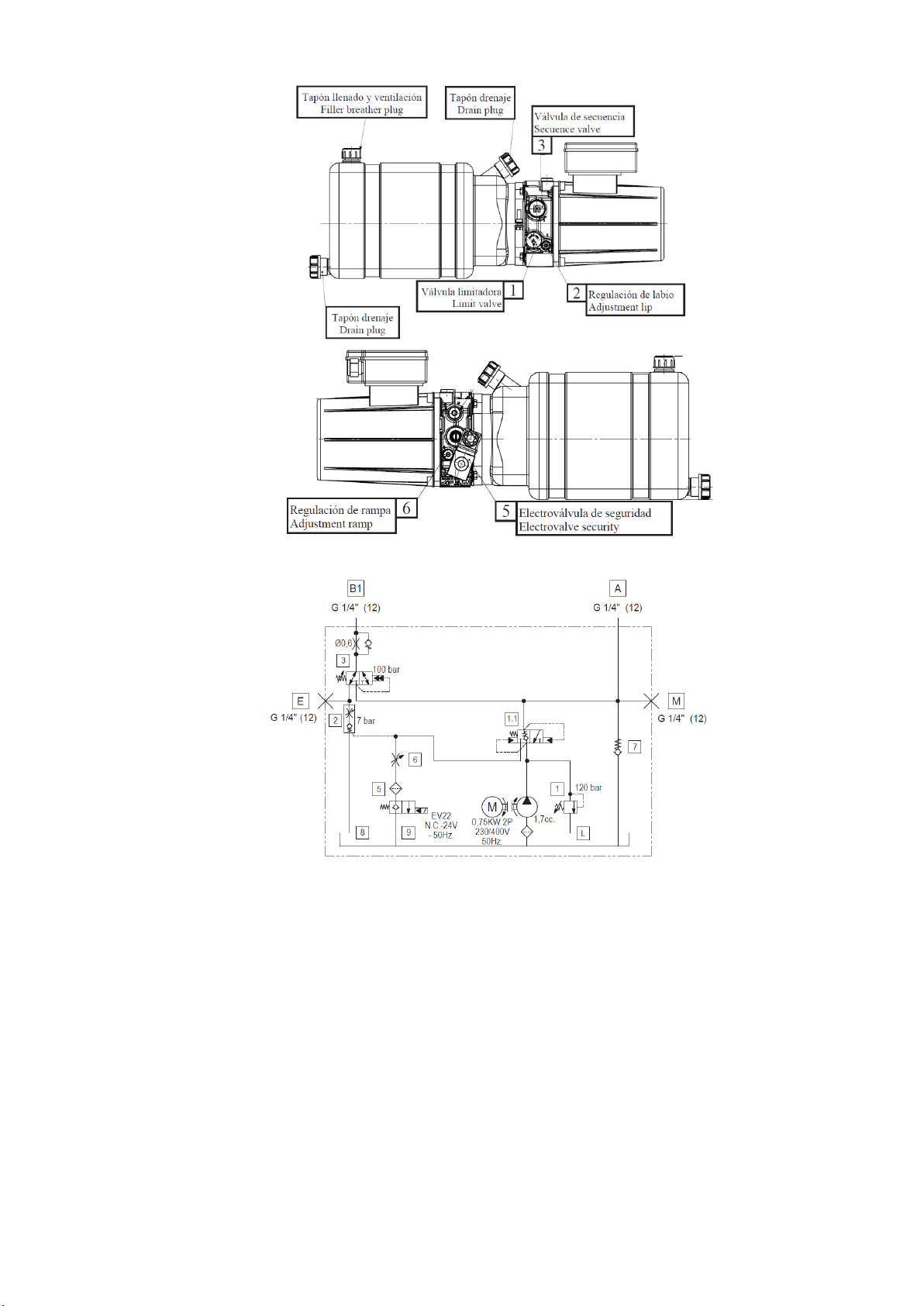

02.07 –Hydraulic power unit ............................................................................................................................ 7

02.07.01 –Hydraulic unit version 03..................................................................................................8

02.07.02 –Hydraulic unit version 07..................................................................................................8

02.08 –Electrical control panel.........................................................................................................................9

02.09 –Safety systems .................................................................................................................................... 9

02.10 –Maintenance...................................................................................................................................... 10

02.10.01 –Hydraulic oil ................................................................................................................... 10

02.10.02 –Grease points................................................................................................................. 10

02.10.03 –Dock leveller descent speed regulation.......................................................................... 10

02.10.04 –Lip opening speed.......................................................................................................... 10

02.10.05 –Maintenance plan........................................................................................................... 10

02.11 –Instructions for use............................................................................................................................. 11

02.11.01 –Before use...................................................................................................................... 11

02.11.02 –During use...................................................................................................................... 11

02.11.03 –After use......................................................................................................................... 12

02.11.04 –Precautions during use. ................................................................................................. 12

03 –CE Declaration................................................................................................................................. 13

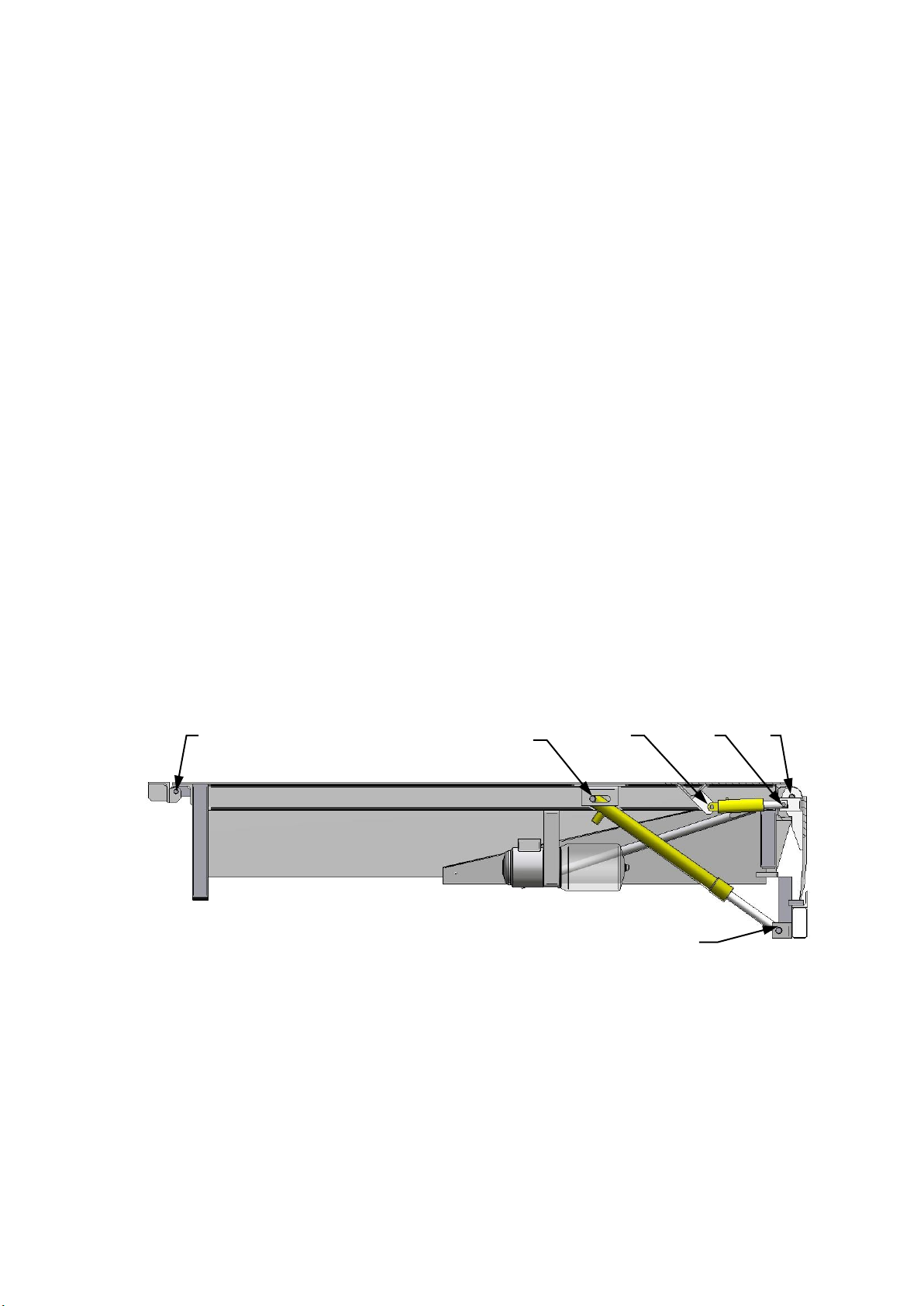

04 –Machine units and parts ................................................................................................................. 14

05 –Installation........................................................................................................................................ 16

05.01 –Transportation.................................................................................................................................... 16

05.02 –Positioning in the pit........................................................................................................................... 16

05.03 –Installing the electrical control panel.................................................................................................. 17

05.04 –Completed installation........................................................................................................................ 18

05.05 –Electrical control panel connection..................................................................................................... 19

05.05.01 –Connecting the power input ........................................................................................... 19

05.05.02 –Motor input connection................................................................................................... 19

05.05.03 –Electro valves connection .............................................................................................. 19

05.05.04 –Description of the connection terminals ......................................................................... 20

05.05.05 –Actions Selection............................................................................................................ 21

05.05.06 –Timers............................................................................................................................ 21

05.05.07 –Operation....................................................................................................................... 21

05.05.08 –Accessories.................................................................................................................... 21

05.05.09 –Characteristics ............................................................................................................... 21

06 –Dismantling...................................................................................................................................... 22

07 –Incidents........................................................................................................................................... 23

07.01 –The panel DOES NOT light up........................................................................................................... 23

07.02 –The leveller DOES NOT rise.............................................................................................................. 24

07.03 –The leveller DOES NOT descend...................................................................................................... 25

07.04 –The lip DOES NOT open or functions very slowly ............................................................................. 25

07.05 –The lip opens before the leveller raises ............................................................................................. 25

08 –Contact............................................................................................................................................. 26