insize ISH-RD200 User manual

MN-ISH-RD200-E

www.insize.com

V0

ISH-RD200

MANUAL DIGITAL

ROCKWELL HARDNESS TESTER

OPERATION MANUAL

1 2

1 产品介绍

ISH-RD200 is supplied with manual load/unload test force part

and is suitable for measuring Rockness hardness of carbide

steel, carbon steel, alloy steel, cast iron and nonferrous metal

etc.

1 . Do not touch the test force dial when loading.

2 . It is necessary to use one-way three-core plug to supply

power, and should follow the rules of local protection.

3. Take off the weight ,indenter and fix the lever inside before

move the hardness tester. And remember to restore the original

packaging and safeguard procedures before long-distance

transport.

Attention Introduction

Structure

1 产品介绍

Installation

2.1 Unpacking and installation:

a. open the wooden box, take out the protection bubbles and

accessary box.

b. open the hardness packaging bag, take out dust cover and

operation manual etc.

c. remove two M10 screws on the base board as picture 1, to

move the hardness tester.

d. the hardness tester should be put on a stable stage after

unpacking, and take the base when moving. And the levelness of

the stage should be no more than 1mm/m.

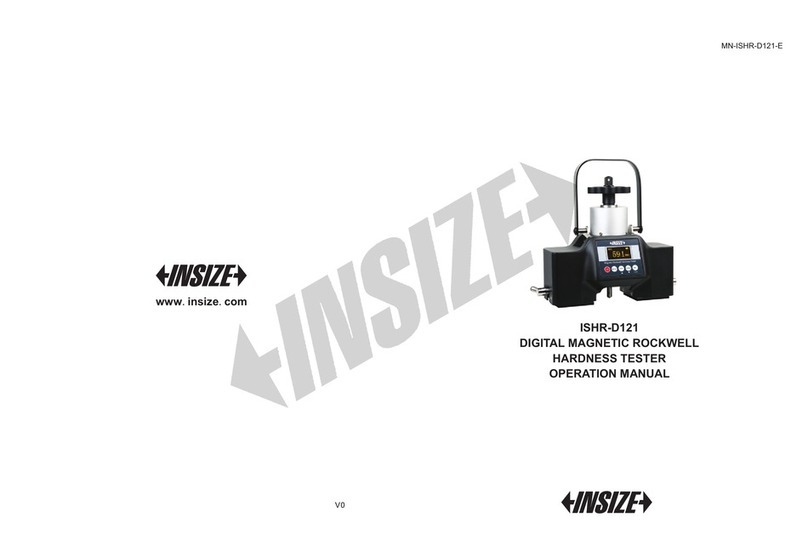

1.up cover back cover operational panel lock screw of indenter

case of lifting screw test force dial 7.lifting handwheel

8.load/unload handle 9.stage 10.indenter

2. 3. 4.

5. 6.

1

2

3

4

5

6

7

8

9

10

34

Picture 2

f Install the weight:

Attention: Do no connect to power when installing the weight.

1) Take out the weights from the accessary box(There is A, B,

C marked on the weights)

2) Rotate the test force dial to 588N, then take out the derrick

and remove the nut.

Picture1

100

490

150

Ø70~80

Attention:

If test sample height over 40mm, it is necessary to make a

circular hole with 70~80mm diameter to make the the lifting screw

move up and down smoothly. The limited position of the screw

going down is 220mm below the stage, and nothing in this area.

The place of the hole is against the base as per picture 2 shows.

e. open the up cover and back cover after fixed the hardness

tester, remove the galloon and bungee which used to fix the

tester. And loosen the case of lifting screw, rotate the lifting

handwheel to make screw go down, then take out the shockproof

pads, and put on the stage.

fix lifting handwheel fix the header bar fix the farmar derrick

fix the lever

3) Put the weight A to the derrick, then tight the nut and put the

derrick to the original place

4) Put weight B and C to the corresponding position.

5) Change the loading and observe if the weights put in to the

grooves, it is working well when weights move smoothly.

16. lever

17. derrick hole

18. derrick

19. outrigger

20. weight C

21. Bweight

22. Aweight

23. nut

16

17

18

19

20

21

22

23

5

6

scale indenter test force(N)

HRA

HRB

HRC

diamond taper indenter

(cone angle )120°

ball indenter

(ball dia.=1.5875mm)

diamond taper indenter

(cone angle120°)

588

980

1471

HRD

HRF

HRG

diamond taper indenter

(cone angle120°)

ball indenter

(ball dia.=1.5875mm) 588

1471

980

ball indenter

(ball dia.=1.5875mm)

e. The measuring surface of the test material should be clear

and without greasy dirt, oxide skin, grooves or clear

machining traces, and the roughness of the measuring

surface no more than 0.8µm is proposed.

scale, test force and weight application form

test force(N)

588

980

1471

scale

HRA/HRF

HRB/HRD

HRC/HRG

g after installation, put the up cover and back cover on.

weight

derrick + weight A

derrick + weight A + weight B

derrick + weight A + weight B + weight C

Usage

3.1 Preparation before use

a. Choose the right stage according to the shape and size of

the test sample.

b. Choose indenters and forces according to the material and

hardness scale(as below table shows).

Material(example)

carbide steel, surface

carburizing and

quenching steel

mild steel, aluminum alloy,

copper alloy, malleable

iron, annealed steel

annealed steel,

tempering steel,

alloy steel, stainless steel

sheet steel,

case-hardening steel

magal, mild cast iron,

thin mild steel plate,

annealed copper alloy

phosphor bronze,

beryllium bronze,

malleable iron

c. Install indenters: put the indenter to spindle hole, ensure

the spindle hole, end face, end handle of indenter and shaft

shoulder clear with nothing. Tighten the lock screw at the end

handle of indenter.

Attention: take the indenter tip with fingertip when

installation to avoid the indenter falling down and cause

indenter tip damaged.

d. Rotate the test force dial to choose test force.

Attention: choose test force should go on under unload state.

7 8

3.2 Hardness Test

a. Switch on the power, turn on the tester, light on to turn on

the digital display screen.

b. Choose the right scale, quantity and conversion value.

c. Put the test material on the stage, and rotate the lifting

handwheel along the pointer to move up the stage.

Attention: Rotate the handwheel lightly and equably to avoid

the test material hit the indenter heavily and cause the

indenter damaged.

d. When the indenter touches the test sample, the figures on

the display would increase, and the spline fit on the left would

also move. When the circle at the end of the spline fit become

solid, the test force finishes loading, and the header would

automatic clear.

e. Rotate the handle to load position and hold about 5

seconds, then return back to unload position, and the result

could be read because the test force has been removed.

Attention: The first measurement or change indenter, stage,

test sample, the first or second measuring result would not be

as a reference. And the distance of adjacent indentation

center would not be less than 2mm, the distance of any

indentation center and the test material margin could not be

less than 1mm.

f. When finish reading results, rotate the lifting handwheel

anti-clockwise to rise down the stage, and the measurement is

over.

g. If the measuring surface is an cylindrical surface with

diameter less than 38mm, the measuring result should be

revised, and the actual hardness value is equal to the

measuring result plus the correction.

Hardness

value (HRB)

Diameter of cylindrical surface(mm)

6 10 13 16 19 22 25

Correction of Rockwell B scale

20

30

40

50

60

70

80

90

100

5.0

4.0

3.5

5.0

4.0

3.5

3.0

2.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

4.5

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.5

4.0

3.5

3.0

3.0

2.5

2.0

1.5

1.5

1.0

3.5

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

3.0

2.5

2.5

2.0

2.0

1.5

1.5

1.0

0.5

9 10

required indentation error and repeatability

scale

HRA

HRB

HRC

hardness range

20~75HRA

75~88HRA

20~45HRB

45~80HRB

80~100HRB

20~70HRC

indentation error repeatability

±2HRA

±1.5HRA

±4HRB

±3HRB

±2HRB

±1.5HRC

≤1.5HRA

≤1.5HRB

≤1.5HRC

4.6 If something unusual happens to the hardness tester, do not

disassemble or adjust any structure, please contact us to solve

this problem.

6 10 13 16 19 22 25 32 38

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

3.0

2.5

2.0

1.5

1.5

1.0

1.0

0.5

0.5

0.5

3.0

2.5

2.0

2.0

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0

3.0

2.5

2.0

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0

2.5

2.5

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

2.0

2.0

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

1.5

1.5

1.5

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

0

1.5

1.0

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0.5

0

0

0

0

1.0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

0

0

0

0

0

1.0

1.0

0.5

0.5

0.5

0.5

0.5

0

0

0

0

0

0

0

0

Hardness

value (HRC)

(HRA)

Diameter of cylindrical surface(mm)

Correction of Rockwell A/C scale

Attention: If the diameter is not included above, interpolation

method is proposed.

For example:

If the measuring surface is an 8mm cylindrical surface, the

correction can be worked out when the measuring hardness

value is 60HRC.

It is easy to find when the hardness value is 60HRC, the

correction of 6mm and 10mm is 1.5 and 1.0, so 1.25 could be

recognized as the correction pf 8mm cylindrical surface.

g. The minimum of the test sample thickness should be more

than ten times of the depth of indentation. After test, the back

of the test material should has no visible deformation traces.

And the relationship of the test sample minimum thickness

and hardness value could be found as per below form:

Maintenance

4.1 Keep clean and away from dust, corrosion and rust in daily

work or after using the hardness tester.

4.2 Be careful when install or take off the indenter, and grease is

also needed if not used for a long time, keep it well.

4.3 The stage and the hardness standard block should be clean,

flat, or any no scratch, paint some antirust grease before store.

4.4 The lifting screw should be lubricated regularly. The detail

operation: take off the stage and the case of screw, paint some

antirust grease on the screw, then rotate the lifting handwheel to

lift the screw up and down, so the grease could be uniform. At this

moment, you can put the case and stage back.

4.5 Check the indentation error and repeatability with hardness

standard block regularly. If the value out of range, need to check

if any wrong with the hardness tester.

Attention: The surface with words marked on the hardness

standard block is the measuring surface.

HRA

HRB

HRC

Hardness value

Mini-thickness

20 30 40 50 60 70 80 90

20 30 40 50 60 70

20 30 40 50 60 70 80 90

1.6 1.4 1.2 1.0 0.8 0.6 0.4 0.2

1.6 1.4 1.2 1.0 0.8 0.6

100

3.3 3.0 2.7 2.4 2.1 1.8 1.5 1.2 0.9

Remark: the unit of mini-thickness is mm.

Hardness value

Mini-thickness

Hardness value

Mini-thickness

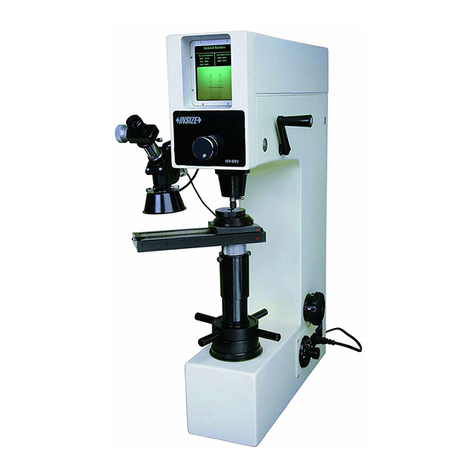

Table of contents

Other insize Test Equipment manuals

insize

insize ISH-MR150 User manual

insize

insize ISH-PHB User manual

insize

insize ISH-PHA User manual

insize

insize ISHB-D200 User manual

insize

insize ISR-S300 User manual

insize

insize ISHR-P151 User manual

insize

insize ISHR-D121 User manual

insize

insize ISH-BRV User manual

insize

insize IST-DCT Series User manual

insize

insize ISF-MT1K User manual