3 4

Code

Application

Thickness requirement

Internal diameter

of flat workpiece

ISHW-B70 ISHW-B75 ISHW-B92

requirement of tube

workpiece

Wall thickness

requirement of

tube workpiece

Hardness range

Min.reading

Accuracy

Dimension

for soft brass for soft steel for hard

and copper and cold-rolled

0.6~8mm

0.6~6mm 0.6~6mm

>Ø10mm >Ø6mm >Ø10mm

0.6~6mm 0.6~6mm0.6~8mm

0~20HW

1HW

±0.5HW(at 5~17HW)

205x30x85mm

aluminum alloy

and hard brass steel

Indenters mode

Standard delivery

Main unit

Spare indenter

Hardness test block

Wrench

1pcs

1pcs

1pcs

1pcs

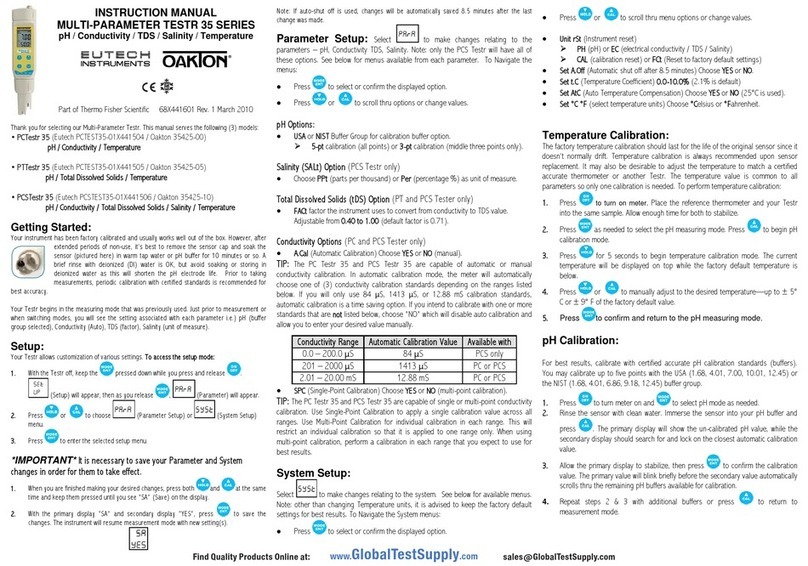

The Webster hardness tester have different mode of indenters.

A. ISHW-L20、B. ISHW-B75 C. ISHW-B92

Screwdriver 1pcs

Calibration sheath(ISHW-L20A )only 1pcs

Verification and calibration

Basic operation

Put the specimen between the anvil and the indenter cylinder, then

press the handle down until the indicator hand come to a stop. Keep

the handle pressed and take the reading.

1. Calibration of the full scale

Press the handle to the bottom without putting any specimen on

the anvil of the hardness tester. Regulate the full-scale adjustment

screw with a small screwdriver to bring the indicator at 20. If the

reading is smaller than 20, the adjustment screw should be regulated

clockwise; if the reading is greater than 20, the adjustment screw

should be regulated anticlockwise. If the pointer can not be set to

1Verification

The operator should verify the accuracy of the tester regularly.

Calibration should be made if the tester is found inaccurate. When

testing on the hardness block, use its upper surface only.

1. Verification of the full scale

Press the handle to the bottom without putting any specimen on

the anvil of the hardness tester. The indicator should point at 20

±0.5HW. If the reading is out of tolerance, full scale calibration

should be carried out.

2. Verification of the test block

Test on the standard test block. For ISHW-L20, ISHW-L20A, IS

HW-L20B testers, the reading should be ±0.5HW of the hardness

number marked on the block. For ISHW-B70, ISHW-B92 testers,

the reading should be 5HW±0.5HW; and for ISHW-B75, the reading

should be 17HW±0.5HW. If the reading is out of tolerance, load

spring calibration should be carried out.

2Calibration

The calibration of the Webster hardness tester includes full scale

calibration and load spring calibration. Full scale calibration is to

set a benchmark, and load spring calibration is to provide a reference

point for the tester. Before calibration of the ISHW-L20A, put the

calibrating sheath on the anvil first.

ISHW-L20A

ISHW-L20B