5 6

buttons, select right material code, the impact direction is down.

Turn off the machine after do setup.

press setup button and On/Off button together (about 2 seconds)

to enter conversion value calibration, the INSIZE logo will blink on

top left corner. Measure 5 times on the surface of workpiece (you

should do enter calibration mode again if get any value which

deviation is large).

2

Input the actual value of workpiece by use up and down buttons

then press return button back to measurement mode.

3

Note: The distance between any two impact position should be ≥3mm.

the distance between impact position and the edge of the sample

should be ≥3mm.

Measurement

Preparation before measuring:

1

Turn on the machine.

Press setup button and set statistic times, select the material

code according to the back label, then press return button

back to measurement mode.

Hardness Tensile strength (MPa)

01.Steel and Cast Steel 11. Low Carbon Steel

02. Alloy Tool Steel 12. Hi Carbon Steel

03. Stainless Steel 13. Chrome Steel

04. Grey Cast Iron 14. Cr-V Steel

05. Ductile Iron 15. Cr-Ni Steel

06. Cast Al Alloys 16. Cr-Mo Steel

07. Cu-Zn Alloys 17. Cr-Ni-Mo Steel

08. Cu-Sn Alloys 18. Cr-Mn-Si Steel

09. Copper 19. Hi Strength Steel

10. Forging Steel 20. Stainless Steel

Note: The value can only convert to “Mpa” When select the

material code 11~20.

Press up arrow button to select right conversion scale.

Note

1. The conversion value is “---” indicated the conversion is out of

range.

2. Conversion value only supplies the general reference, which

may result in some offset. Precisely conversion generally needs

related comparative tests.

:

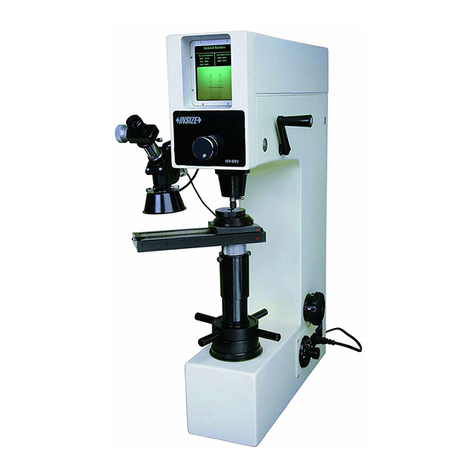

Sample Preparation:

Inappropriate sample will cause a great measurement error.

Therefore, users should make the necessary handling and

preparation under the original conditions of sample.

Preparation of the sample and the surface of test should be

coincident with the following basic requirements:

1) During the process of sample surface preparation, users

should avoid the impacts of cold processing and thermal

processing.

2) The sample surface is plane for better, the test surface

should be with a metallic sheen, and not involve oxide layer

orother stains.

3) Roughness of the test surface Ra ≤ 1.6

4) Sample must be of sufficient quality and rigidity. If it's lack

of quality and rigidity, it may cause displacement or shaking in

the process of testing impact, which can lead to large errors.

Generally speaking, if the sample quality is more than 5kg can

be directly tested; if the sample quality is 2~5kgs, the sample

should be taken in fixation test by means of appropriate

clamping; if the sample quality is 0.1~2kgs, the sample

should be conducted coupling before the test; if the sample

qu a lit y is les s t han 0.1 k g, t his har d ne s s te ste r i s

inappropriate to use.

Coupling method: Testing sample's back should be prepared

to make a plane as a supporting surface with a smooth

formation. Filling with a little coupling substance (Industry

Vaseline can be used), users can now press to the surface of

the supporting object (The weight of supporting object should

be more than 5 kg, and it can be replaced by test block) to

stick into integration.

5) Samples should be thick enough and with sufficient surface

absorption layered. If users use D-type impact device, the

thickness of sample should not be less than 5mm, and surface

absorption layer (or surface-hardening layer) should not be

less than 0.8mm. To accurately measure the hardness of the

material, the best way is to remove the surface-hardening

material, the best way is to remove the surface-hardening

layer by processing.

6) When testing sample surface is not horizontal, the

curvature radius of testing and nearby surface should be