3 4

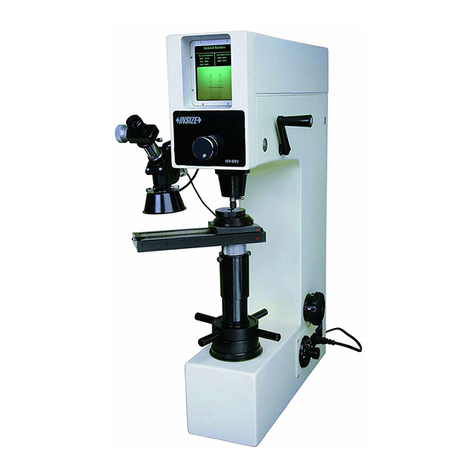

Main Technical Parameters

Initial test force: 10kg

Test force: 30, 100, 150kg

Force applying method: by screw

Indenter: 120°diamond cone, Ø1.588mm carbide balls

Testing Items: HRC, HRB, HRA

Resolution: 1HR

Accuracy: Meets the requirements of ISO6508/6506

Application: All metals, including steel, forged steel, cast iron, copper,

copper alloy, aluminum, aluminum alloy and carbides etc.

Operation

Test Conditions:

Make sure the surface is flat and smooth. It is forbidden to have scale,

decarburized layer, steel pit or dust on the surface of the part.

1

2

3

4

Set the load dial to “0”:

Check the indicator, it should rest exactly on the red dot “0” on the

indicator dial. If it doesn’t, adjust the dial by turning the bezel to locate

the red dot.

Fix the test piece:

Put the test piece into the opening of the tester with its back side

contacting the anvil tight, and be sure to keep its testing surface vertical

to the principal axis of the indenter. Turn the hand wheel to make the

main shaft of the tester move to the left, and the indenter is made to hit

on the test piece surface.

Apply initial test force:

Slowly turn the hand wheel

clockwise to bring the indicator

to the position of initial force

F0 (for Rockwell Hardness

Tester F0=10Kg.

5Set the full scale line to “0”:

Rotate the rotational drum dial anticlockwise until its pin rests against

the upper edge of the magnifier. Meanwhile, the operator should adjust

the observing angle to make the full-scale benchmark line on the fixed

drum dial (the red scale mark 130, black scale mark 100) exactly

aligned beneath the reading scale mark of the magnifier. The operator

should keep this viewing angle also known as the viewing angle for

reading the hardness value until the test is finished.

6Load and unload major test force:

Rotate the hand wheel stably clockwise to bring the indicator to the

position of total test force F=F0+F1 (e.g., for HRC scale, F=150kg). The

indicator should be aligned exactly to the marked scale of the selected

test force. If the goes beyond the scale mark, the testing

should be considered as failure. Then unload the test force and choose

a new point on the test piece to make a new test.

The time duration from loading initial test force to loading total test

force should be no more than 8 seconds.

After loading total test force, the test force should be maintained 3 to

5 seconds. Then completely unload major test force within 2 seconds

to bring the indicator back to the position of initial test force F0.

indicator

Test force

60kg

100kg

150kg

Scale

HRA

HRB

HRC