insize ISR-C300 User manual

MN-ISR-C300-E

www.insize.com

V3

ROUGHNESS TESTER

(SEPARABLE TYPE)

OPERATION MANUAL

ISR-C300

1 2

1Features

The surfaces roughness tester is a small handheld instrument, for shop

floor use and mobile measure, it operation simple, function overall,

measure fast, accuracy stability, take convenience. This tester applies to

production site and can be used to measure surface roughness of various

machinery-processed parts. This tester is capable of evaluating surface

textures with a variety of parameters according to various international

standard. The measurement results are displayed digital/graphically on the

color graphic LCD display, And output to the printer.

Composite structure of main display unit ,driver unit and Sensor.

Electromechanical integration design, small size, light weight, easy to

operation;

Data can be output to Excel by connecting with computer via bluetooth

or USB cable;

Support Bluetooth printing and mobile APP wireless operation;

Multi parameters: Ra, Rz, Rq, Rt, Rp, Rv, R3z, R3y, Rz(JIS), Rs, Rsk,

Rsm, Rku, Rc, Ry, Rmax, Rmr;

320μm Large measurement range;

The 3.5-inch color graphic LCD provides excellent readability and an

intuitive display that is easy to negotiate. The LCD of 480*320 dot

matrix includes a adjustable backlight for improved visibility in dark

environments. Wide angle of view;

DSP chip control and data processing, high speed, low power

consumption;

Display full information, intuitive and graphical displays all parameters;

The tester Complies with the following standards:ISO-1997, DIN, ANSI,

JIS2001;

Built-in 3200mAh lithium-ion rechargeable battery and control circuit,

high capacity, no memory effect;

Can work more than 50 hours while the power is enough;

Large capacity data storage, can store 100 item of raw data and

measured profile;

Real-time clock setting and display for easy data recording and storage

With automatic sleep, automatic shutdown power-saving features;

Reliable circuit and software design of prevent the motor stuck;

Instrument can display a variety of information tips and instructions. For

example Measurement result display, the menu prompts and error

messages;

Introduction Metal case design for driver unit, rugged, compact, portable, high

reliability;

Can connected to the computer and printer;

All parameters can be printed or print any of the parameters which set

by the user;

2Measurement principle

When measuring roughness of part surface, the pickup is placed on

the surface of the part and

then tracing the surface at constant rate. The pickup acquires the

surface roughness by the sharp stylus in pickup. The roughness

causes displacement of pickup which results in change of inductive

value of induction coils thus generate analogue signal which is in

proportion to surface roughness at output end of phase-sensitive

rectifier. This signal enters data collection system after amplification

and level conversion. After that, those collected data are processed

with digital filtering and parameter calculation by DSP chip and the

measuring result can be read on LCD, printed through printer and

communicated with PC.

2

3Standard Configuration

Item

Standard probe

Calibration block and support

Connecting cable

Magnetic stand adapter

Adjustable stand

Touch pen

USBcableandsoftware

AC/DC adapter

1pc

1pc

1pc of each

1pc of each

1pc

1pc

1pc

1pc

1pc

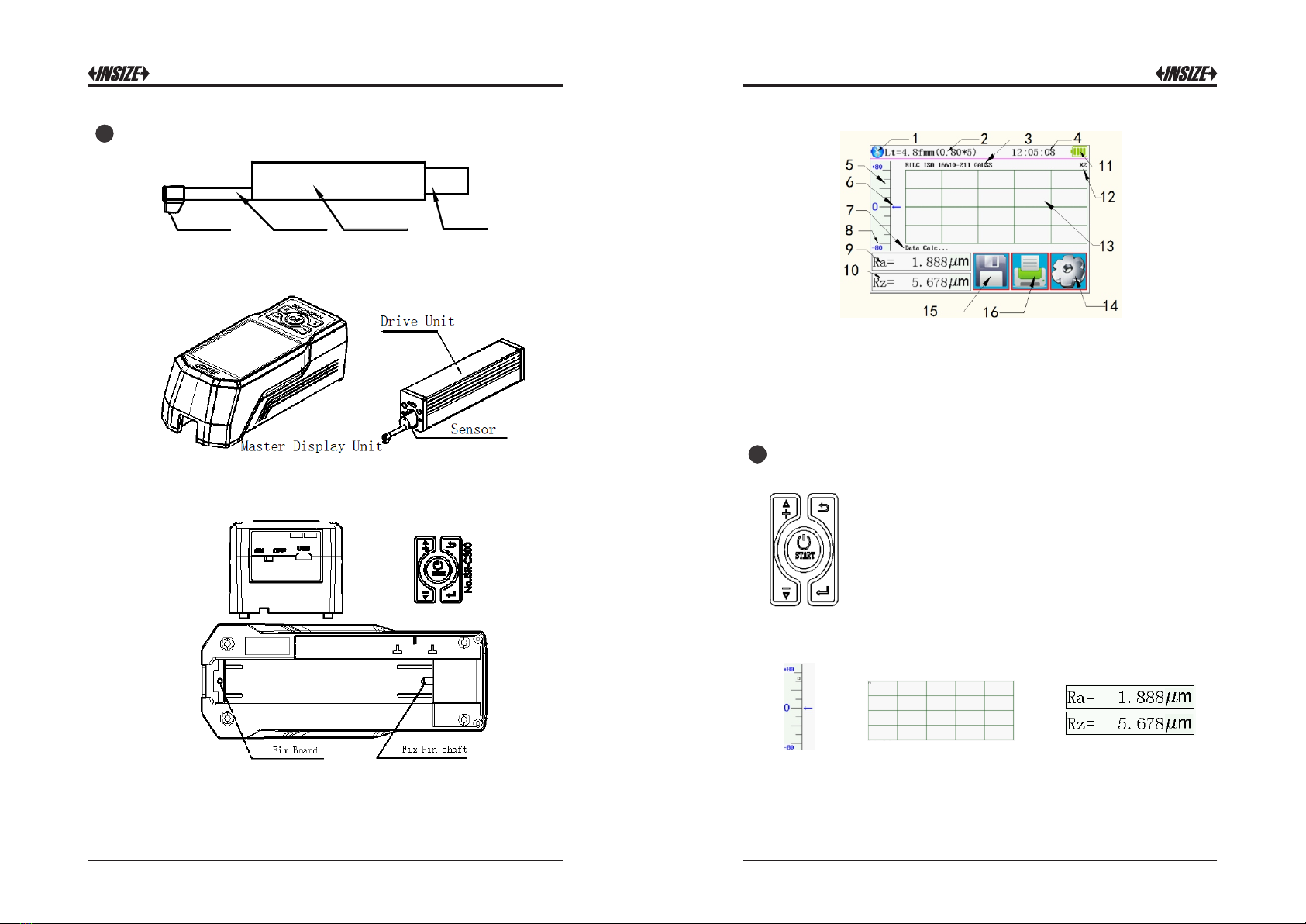

4Name of each part

Sensor

3

4

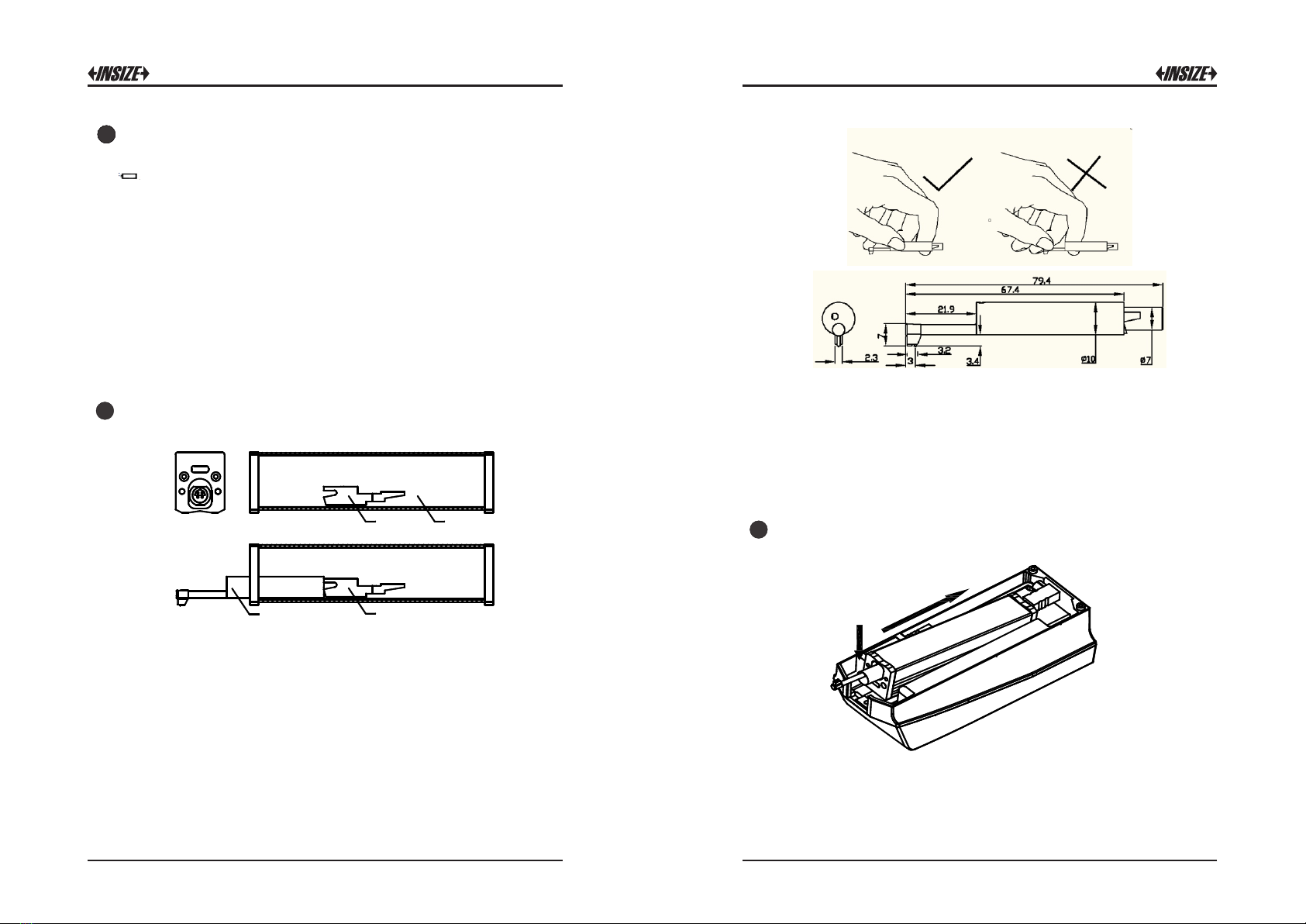

{┱〈┆■┧ Tube Sensor body Socket

Front view

Back view

Power switch is a total power switch on the instrument.

Turned off when not in use for a long time.

1 Bluetooth Mark;2 Assess length;3 Filter;4 Working Time;

5 Start Touch key area;6 Pickup position;7 Hint information area;

8 Range;9 Master results display;10 Slave results display;

11 Battery level;12 Profile scale;13 Profile display area;

14 Menu touch key;15 Save touch key;16 Print touch key

5Buttons define

Power key: Press and hold START 2 seconds On/Off tester

Start measurement key: Start the instrument to measuring

Up /Add key: Increase the value

Cancel / Exit key: Used to exit the menu and unset

Enter key: Confirmation setting

Down / decrease key: decreased the value

touch key of Hidden

Start touch key Profile zoom touch key Multi results and

Profile touch key

56

When battery voltage is too low (that is, battery voltage symbol display

on screen to prompt low voltage), the instrument should be

charged as soon as possible. USB port of the instrument for charging.

You can use the built-in power adapter for charging, you can also use

computer's USB port for charging. If use the other power adapter for

charging, the output voltage should be 5V DC , the current should be

greater than 1000mA.

Instrument displays charging animation when charging after full

animation ends, the display is full of symbols. Charging time of 5

hours.

This instrument adopts lithium ion chargeable battery without memory

effect and charging can be fulfilled at any time without affecting normal

operation of the instrument.

6Battery Charging

6

6

6

6

6

6

6

7Connection method of sensor and drive unit

When installing and remove sensors, turn off the power first.

a 2

2 3

1 sensor 2 Socket of drive unit 3 Drive unit

For installation, hold the main body of sensor with hand, push it into

socket at the the drive unit as shown in Figure and then slightly pushed

it to the end of the sheath. To remove, hold the main body of sensor or

the root of protective sheath with hand and slowly pull it out.

1. Sensor is key part of this tester and great attention.should be paid to

it.

2. During installation and remove, the stylus of sensor should not be

touched in order to avoid damage and affecting measurement.

3. Connection of sensor should be reliable during installation.

4. The sensor doesn't need to be removed when not in use.

5. Calibration is recommended after each new sensor is installed.

8Connection method of Drive unit and Main Display unit

a

2

Installation method

1 The driver unit is embedded into the main display unit according to

the direction of arrow 1, so that it is installed on the fixed pin shaft.

2 Press the drive unit in the direction of arrow 1 and down the direction

of arrow 2 to install the driver unit on the fixed plate.

7

8

Remove method

a

2

3

1 Press the driver unit toward arrow 1 and lift it toward arrow 2.

Remove the driver unit from the fixed plate.

2 Pull the driver unit in the direction of arrow 3 and take out the drive

unit.

9Extension cable usage

If the drive unit is not installed on the main display unit, please connect

the main display unit and the drive unit with the extension cable as

shown in the following figure before using it.

1 Preparation for Measurement

Switch-on to check if battery voltage is normal;

Clear the surface of part to be measured;

Place the instrument correctly, stably and reliably on the surface to be

measured;

Trace of the pickup must be vertical to the direction of process line of

the measured surface.

Measuring Operation

2Turning On/Off

Press the POWER key to hold 2 seconds after the instrument will

automatically boot, boot will display type, name and manufacturer

information, and then enter the basic measurement status main display

interface.

In any state, press the POWER key to hold 2 seconds after the

instrument will be turned off.

Introductions:

1. The next boot will be displayed when the last shutdown set content.

2. Startup and shutdown, press and hold the key for about 2 seconds to

open the instrument will perform the appropriate action.

3. Long time not to use, the instrument should be on the side of the

power switch turned off.

3Pickup Position

First, view pickup position to determine the location of the sensor. The

best location is in the middle position of the range.

Arrow indicates if it is not at zero point. The instrument can also be

measured normally.

As long as the entire measurement process does not exceed the set

range, it will not affect the measurement results.

9

10

4Start measurement

In the main interface display mode,

Press the Start key or Start key touch area to start measuring.

The measurement can be stopped according to ESC.

5Measurement result display

After the measurement, if you need to look at all the measurement

results, touch the main and secondary display area will be able to see

all the calculation results. The touch profile display area will zoom the

profile by 1-2-4-8.

More results touch area Zoom key touch area

The instrument can be connected to the printer. The measurement

results will be printed. After measurement, Press key to print the

measured data to a serial printer.

The instrument can set the print output according to the actual

requirements of arbitrary parameters choose to print or print all the

parameters, how to set the parameters, refer to "Print Settings".

6Print measurement results

6

7Storage measurement results

In the main display interface mode, press the key to save the

measurement results stored in the instrument memory. Instrument built-

in large capacity memory, can store 100 groups of raw data and profile

data.

Data storage recording date and time the file name automatically

generated according to the last data record is always stored the

most recent recording time, the last data record stored recording

record number will be 001.

8Setting Main Menu

In the main display interface mode, press the key enter main menu

11

12

9System Setting

Touch system setting area can page up system settings.

1.Master results display and slave results display

2.BPS rate setting

The BPS rate of communication between instrument and printer or

between instrument and APP of mobile phone.

Default BPS rate 115.2K

3.Auto shutdown

Set to ON instrument for 600 seconds without operation will be

automatically shutdown . When OFF is set, it will work all the time.

4.Bluetooth mode

There are 2 mode to operate Bluetooth module, print mode and

data transmission mode.

Set it to print when Bluetooth printing is needed and to Ctrl when

communicating with mobile APP

Bluetooth switch can only be operated when Bluetooth power is off.

5.Bluetooth Power

Please set the Bluetooth mode first, then turn ON the Bluetooth

power, the instrument will automatically set the Bluetooth module

as required.

Because of the unnecessary battery capacity loss caused by the

long-term opening of the Bluetooth function, the instrument will turn

off the Bluetooth power after each boot. If you need to use

Bluetooth function, please open it yourself.

6.Touch Screen calibration

When the instrument is manufactured, the touch screen has been

calibrated. Generally, calibration is no longer required, but the

physical parameters will change over time. If you find that the

button is not correct, please calibrate again. Please follow the

screen prompts.

13

14

7.Rpc Details settings

According to user's demand, Rpc-parameter's calculation can be

selected from "μm" and "%".

8.Date and Time settings

If you want to change the date and time, please press STOP first,

after the modification is finished, press START.

9.LCD Display brightness settings

10.Reset factory settings

11.Format memory

Data formatting is the deletion of data records. Once formatted, all

data will be emptied. Before the data formatting, the instrument has

the confirmation prompt information. After the user confirms, the

data will not be restored. Please proceed with caution.

Format memory takes about 1 minutes, please do not turn off

the power.

10 Measuring Condition Settings

Cut off length λc

0.25mm;0.80mm;2.50mm

Number of Sampling lengths

(×n)

1-5

Range

±20μm; ±40μm; ±80μm; ±160μm

Unit

Inchmm

Filter

RC;PC-RC;GUASS;D -P

15

16

11 Record Management

Click on the corresponding record to see the details of the record.

12 Software Information

Instruments software and hardware information can help users easily

upgrade and maintain the product, unique serial number of the

instrument software information items are displayed.

13 Parameter calibration

Before measuring, the instrument usually required calibration on

standard calibration block. The instrument is configured with a standard

calibration block, before measurement, instruments should test on the

block. Under normal circumstances, when the difference between the

measured value and the block value is in the acceptable range, the

measurement value is valid, can be measured directly.

If the measured value and the block value which difference is greater

than a accuracy error range of the instrument, or the user require high

accuracy, can be used to correct the indication calibration function and

improve measurement accuracy. The value of the calibration procedure

is as shown.

Illustration is based on a model calibrated 1.63μm steps to calibrate the

model for the actual calibration of the nominal value of the set value.

1. Under normal circumstances, the instrument in the factory have been

rigorously tested, showing error is much less than ± 10%, in this case,

the user is not showing the value of the calibration frequently used

functions.

2. After setting the calibration value, you must press the START key for

a full measurement, instrument calibration to be valid.

3. New parameters after calibration must be carried out once a

complete measurement and press the Save&Exit key is stored in the

instrument.

4. Press "Exit"key to return the menu without saving calibration results.

14 Print Function setup

The instrument can be tested according to the actual requirements of

any parameter selection Print or Print All, the steps shown in Figure.

17

18

و ﮭ ى%

6.5%

5.1%

4.1%

20%

15%

10%

5%

10 0%

C( Rt)

10 0%

Rm r0Rm r

C( Rt)

Rq= 1691よm

Rz= 4.2 75よm

Ra= 1.5 98よm

** ***** ** ***** ***** *** **

Su rface R oughn ess T est er

** ***** ** ***** ***** *** **

20 13.04 .1 8 11:05 :08

Ln = 0. 8mmX5

Ra nge = 40um

Fi lter = GA USS

Ra = 1. 598um

Rz = 4. 275um

Rq = 1. 691um

Rt = 5. 113um

Rp = 1. 966um

Rv = 2. 309um

Rs = 0. 08mm

R3 z = 3 .853u m

R3 y = 4 .059u m

Rz JIS = 3.90 1um

Rs k = - 0.16

Rk u = 1 .18

Rs m = 0 .08mm

10 0% Rm r0

10 0% C(Rt)

C( Rt) Rmr

1 0% 7. 2%

2 0% 41. 8%

3 0% 49. 8%

4 0% 52. 1%

5 0% 54. 2%

6 0% 55. 9%

7 0% 58. 6%

8 0% 66. 5%

9 0% 96. 6%

15 Data output to Excel

Data can be output to Excel by connecting with computer via bluetooth.

set up Communication port, baud rate, data bit, parity check, stop bit,

traffic control and other data.

1. The roughness meter is set to print mode, the baud rate is set to

115.2k, and bluetooth pairing is turned on Connect the instrument to

the computer via bluetooth receiver.

2. Inset bluetooth receiver receiver to the computer , When the green

light shows two flashes at the interval, the pairing is successful, the

data can be directly transmitted to Excel by press “Enter” key .

16 Mobile APP

This instrument supports the wireless Bluetooth function, such as in the

high altitude or pipeline operation is inconvenient to directly operate the

instrument keys, Bluetooth remote operation function can be used.

This mobile phone APP currently supports Android version 6 or more.

Use mobile phone APP to control the instrument, please set the

Bluetooth mode to data transmission mode, and turn on the Bluetooth

power ,the connection password is 1234, It can be used when connect

with mobile phone via bluetooth.

Note: please note that the parameters of "result" is selected in "print

details set", otherwise there will be no data output to Excel

19

20

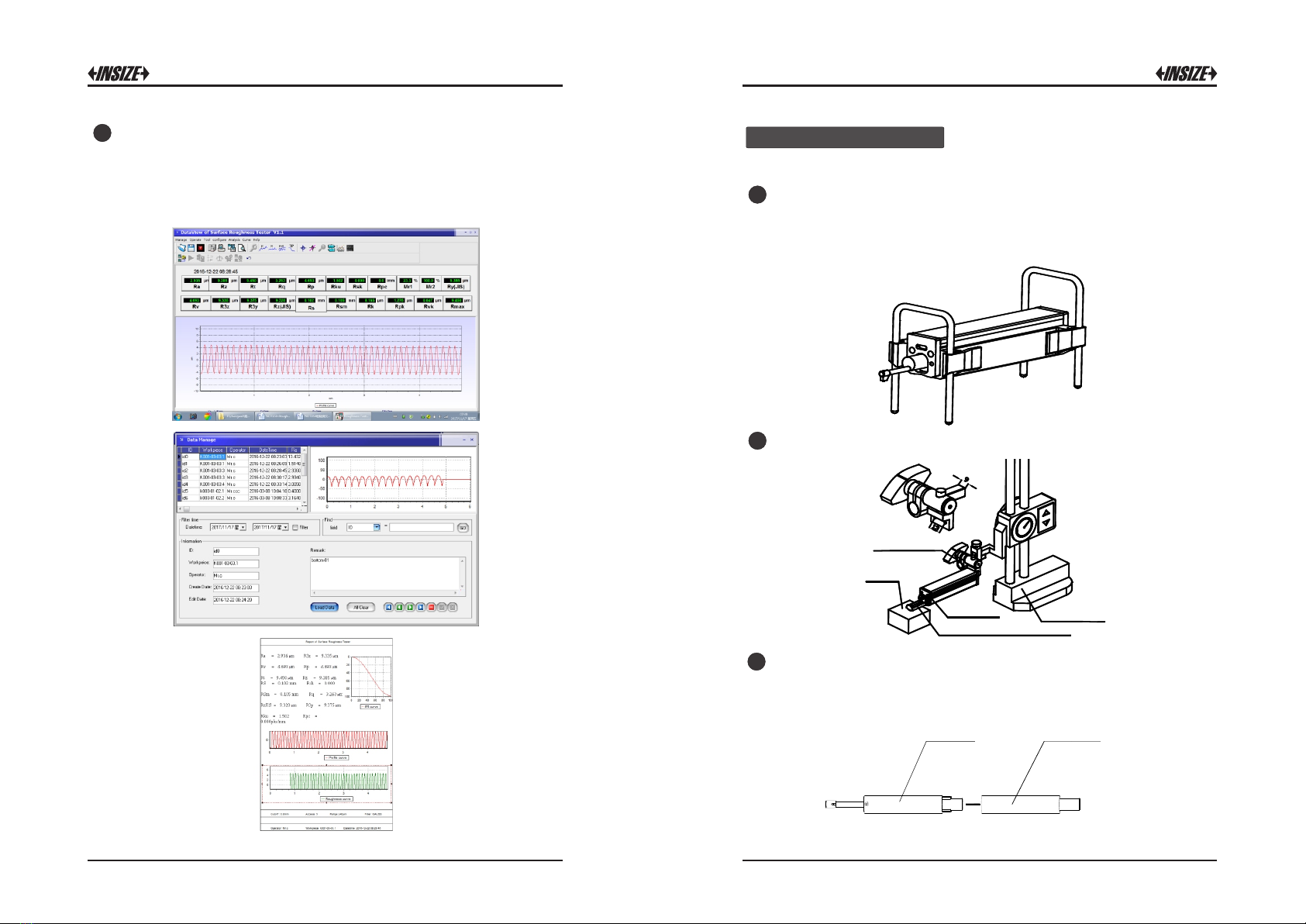

17 Dataview of software

Dataview of software can easily be waveform analysis and print

measurement results uploaded to the PC machine.

Use USB cable to connect computer data processing software to set

the tester baud rate 921.6 k.

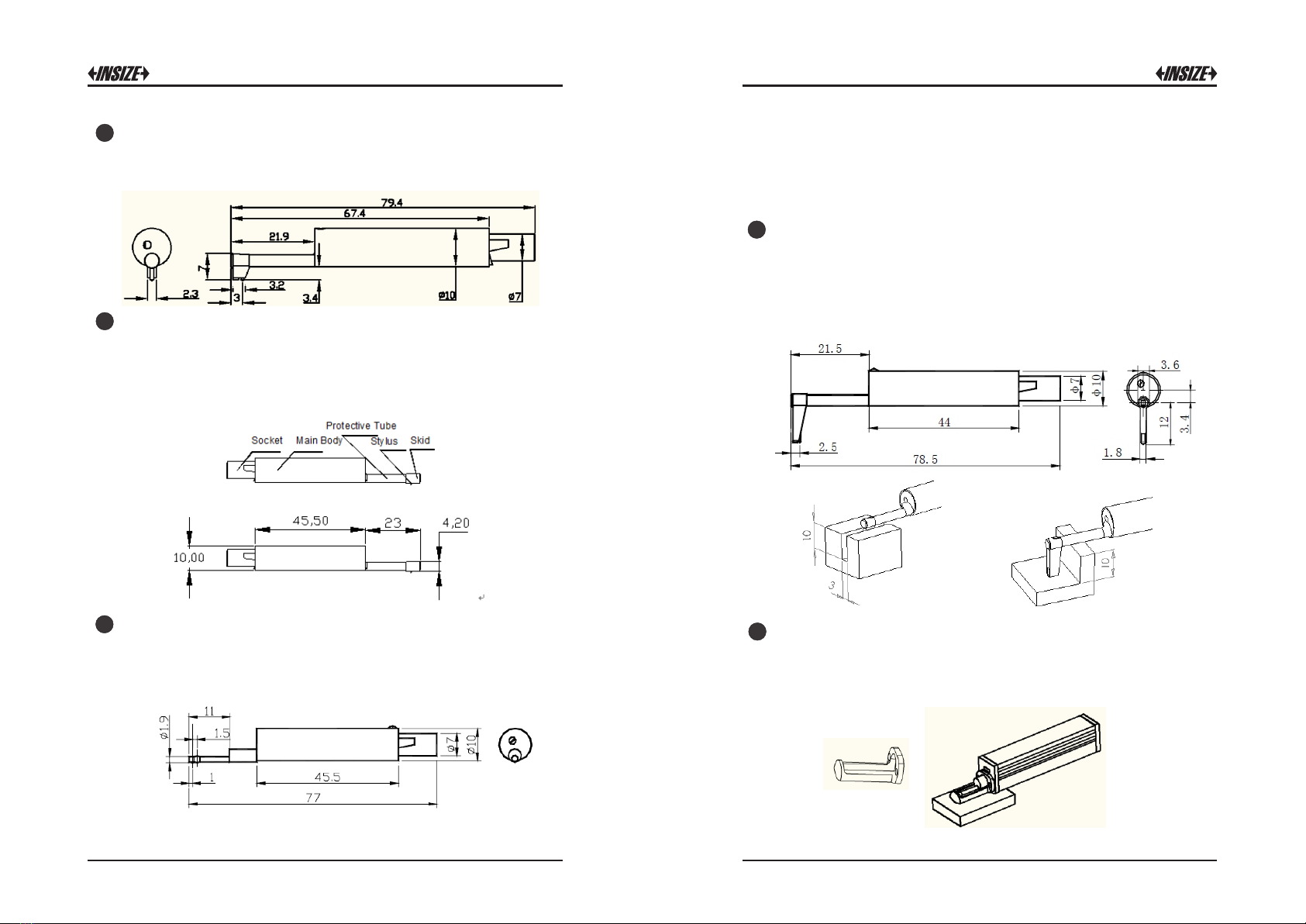

1Adjustable height support feet

When the measured surface of the workpiece is smaller than the bases

of the instrument, the adjustable height support feet can be used as an

auxiliary support to complete the measurement.

2Height gauge adapter

Options and Usage

a∞…┧■┣∞∏ └Ⅶ─∞Ⅷ┱

Height gauge adapte

Protecting Nosepiece

Drive unit Height Gauge

3Extension rod (50mm)

Extension rod increases the depth for pickup to enter the part. Length

of extending rod is 50mm.

9ŝĊś■ŕ ╜■┼ w◘ŕ

Sensor

21 22

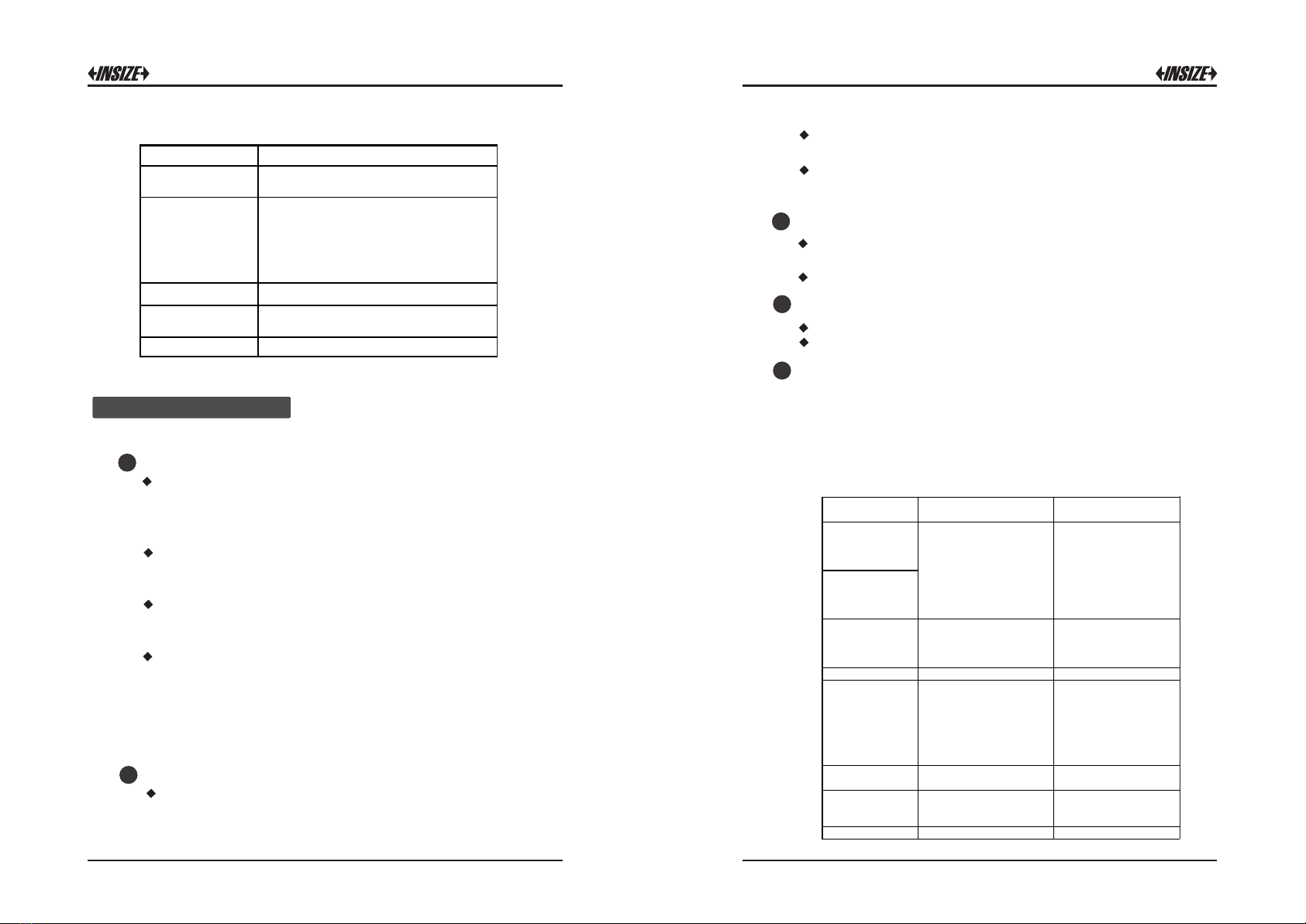

4Groove Sensor

5Small hole Sensor

The groove sensor is the standard sensor of the roughness meter, and

its demension are as follows:

Small hole sensor can measure the plane, inclined plane, cone surface,

inner hole and other surface roughness.

Minimum measurable hole diameter:Ф5mm

The use of small hole sensors must be installed on the measuring

stand for measurement.

6Extra small hole sensor

Using Extra small hole sensor, the inner surfaces of holes with radius

more than 2.5mm can be measured. Refer to the following Figure for

detailed dimension.

Extra small hole sensor operation method

The skid of the extra small hole sensor is behind the stylus. When it

contacts the workpiece, the pickup position is first high and then low.

The use of extra small hole sensors must be installed on the measuring

stand for measurement.

With deep groove sensor, it is possible to measure groove with width

wider than 3mm and depth deeper than 10mm, or the surface

roughness of step with height less than 10mm, Also can used to

measure the planar, cylindrical used with platform. please see figure for

detailed dimension.

7Deep Groove Sensor

8Support for flat surface

It is suitable for measuring the roughness of the measured object which

is smaller than the roughness tester and the measuring plane is plane.

The support can protect the sensor effectively.

23 24

9Support for cylindrical surface

It is suitable for measuring the roughness of cylindrical object which

can not be measured directly. The nosepiece can protect the sensor

effectively.

Technical Parameter and Features

10 Bluetooth printer

The printer is a Bluetooth interface, , and the roughness meter needs

to be matched with the wave, the specific rate is set to 115.2k, and the

bluetooth mode is set to "print" mode and turn on the bluetooth, the BT

indicator lights up when the roughness instrument is connected

successfully.

Note: in all of the above different measurement methods, it is

necessary to ensure that the probe has a certain downforce.The touch

pointer on the screen shall not prevail. The visual probe shall be

parallel to the object under test.

Name

Content

Measurement

Range

The Z axis

(vertical)

320μm (-160μm~160μm) / 12600よin (-6300よin~+6300よin)

The X axis

(horizontal)

17.5mm/ 0.69"

Resolution

The Z axis

(vertical)

0.002μm/±20μm

0.004μm/±40μm

0.008μm/±80μm

0.02μm/±160μm

Measurement

item

Evaluation

Parameter

Ra Rz Rq Rt Rc Rp Rv R3z R3y Rz(JIS) Ry

Rs Rsk Rku Rmax Rsm Rmr RPc Rk Rpk Rvk

Mr1Mr2

Standard

ISO4287,ANSI b46.1,DIN4768,JISb601

Graphic

Primary profile, Roughness profile, load curves

LCD dimensions

3.5-inch 480*320

Filter

RC,PC-RC,Gauss,D-P

The sampling length (lr)

0.25,0.8,2.5mm

Assessment length (ln)

Ln= lr×n n=1~5

Sensor

Principle

The displacement differential inductance

Stylus tip

Natural Diamond, 90 cone angle, 5μm tip radius

Measuring force

4mN

Skid force

Less than 400mN

Skid

RubyLongitudinal radius 40mm

Measuring speed

lr=0.25, Vt=0.135mm/s

lr=0.8, Vt=0. 5mm/s

lr=2. 5, Vt=1mm/s

Return Vt=1mm/s

Accuracy

No more than±10%

Repeatability

No more than 6%

Power supply

Built-in 3.7VLithium ion batteryCharger :DC5V,800mA/5hour

Working Time

More than 50 hours

SIZE

L×W×H

Display unit

158×55×52mm

Drive unit

115×23×27mm

Mass

About 500g(Display Unit + Dirve Unit + Sensor)

working Environment

Temperature- 20 ~ 40

Humidity< 90% RH

Store and Transportation

Temperature- 40 ~ 60

Humidity< 90% RH

25 26

Measuring Range

Param eter

M easuring range

Ra

Rq

0.005μm ~ 32μm

Rz

R3z

R y

Rt

Rp

Rm

0.02μm ~ 320μm

Sk

0 ~ 100%

S

Sm

1m m

tp

0 ~ 100%

General Maintenance

probe

Any time swap probes are to be especially careful, careful not to

touch the guide head and a stylus, because this is a key part of the

whole instrument, to try to hold the probe guide head bracket roots

(the front of the body) plug.

To complete the measurement work, please timely probe into the

box;

3. Please pay attention to protect the needle part measuring probe.

The probe's precision components, any knock, touch, fall off

phenomenon may damage the probe, should try to avoid such

situations.

The probe is a damageable parts, do not belong to the scope of

warranty parts, only provide repair. In order not to affect the

measurement work, users are advised to buy backup probe used

for emergency.

1

Main Unit

The instrument is a precision measuring instrument, should

always be handled with care, to avoid the shock.

Pay attention to add oil to maintain regularly every year to

prevent internal wear.

Battery

Always observe the battery prompt, when the low voltage,

please charge.

The charging time is 3 hours, try not to long time charge.

Standard Sample Plate

The surface of a standard sample plate must be kept clean.

To avoid scratches on the surface of sample area.

Troubleshooting

When the tester breaks down, handle the troubles according to

measures described on Fault Information. If troubles still exist,

please return the instrument to factory for repair. Users should not

dismantle and repair the device by themselves. Returned

instrument should be accompanied with sample plate attached.

Phenomenon of problem should be explained.

2

3

4

5

Error message

Cause

Solutions method

After the boot, the

display interface is

about 1 minutes,

turn off.

The cable plug is not tight.

Re insert socket

The sound of the

motor can not be

heard after turning

on the tester.

Touch screen failure

Touch Parameter loss

touch screen calibration

In the main display

interface, press ESC key for

6 seconds.

Motor error

Motor stuck

Reboot

Out of Range

1. The measured surface

signal exceeding the

measurement range

2. Placed away from the

center of the stylus position

Increase Measuring range

Adjust the Stylus position

No test data

After the boot does not

measure.

The actual measurement:

one time

Measurement

Accuracy

Out of Range

Set the parameter error

Calibration data error

Set the parameter

measurement

Calibrate the tester

Pay attention to maintaining the Main Unit surface clean, often

with a soft dry cloth to clean its surface.

27 28

References

Terms

The instrument calculate parameters on the filter profile and the

direct profile , all calculated in line with the GB / T 3505-2000

"Geometrical Product Specification(GPS) —— Surface texture:

Profile method——Term,definitions and surface texture

parameters."

Terms

Filtered profile: profile signal after primary profile is filtered to

remove waviness.

D-P (direct-profile): adopt central line of Least Square Algorithm.

RC filter: analogue 2RC filter with phase difference.

PC-RC filter: RC filter with phase-correction.

Gauss filter: ISO11562.

Traversing Length

Parameters Definitions

Arithmetical Mean Deviation of Profile Ra

Ra is arithmetic mean of the absolute values of profile deviation

Z(x) from mean within sampling length.

Z1

Z2

Zi Zn

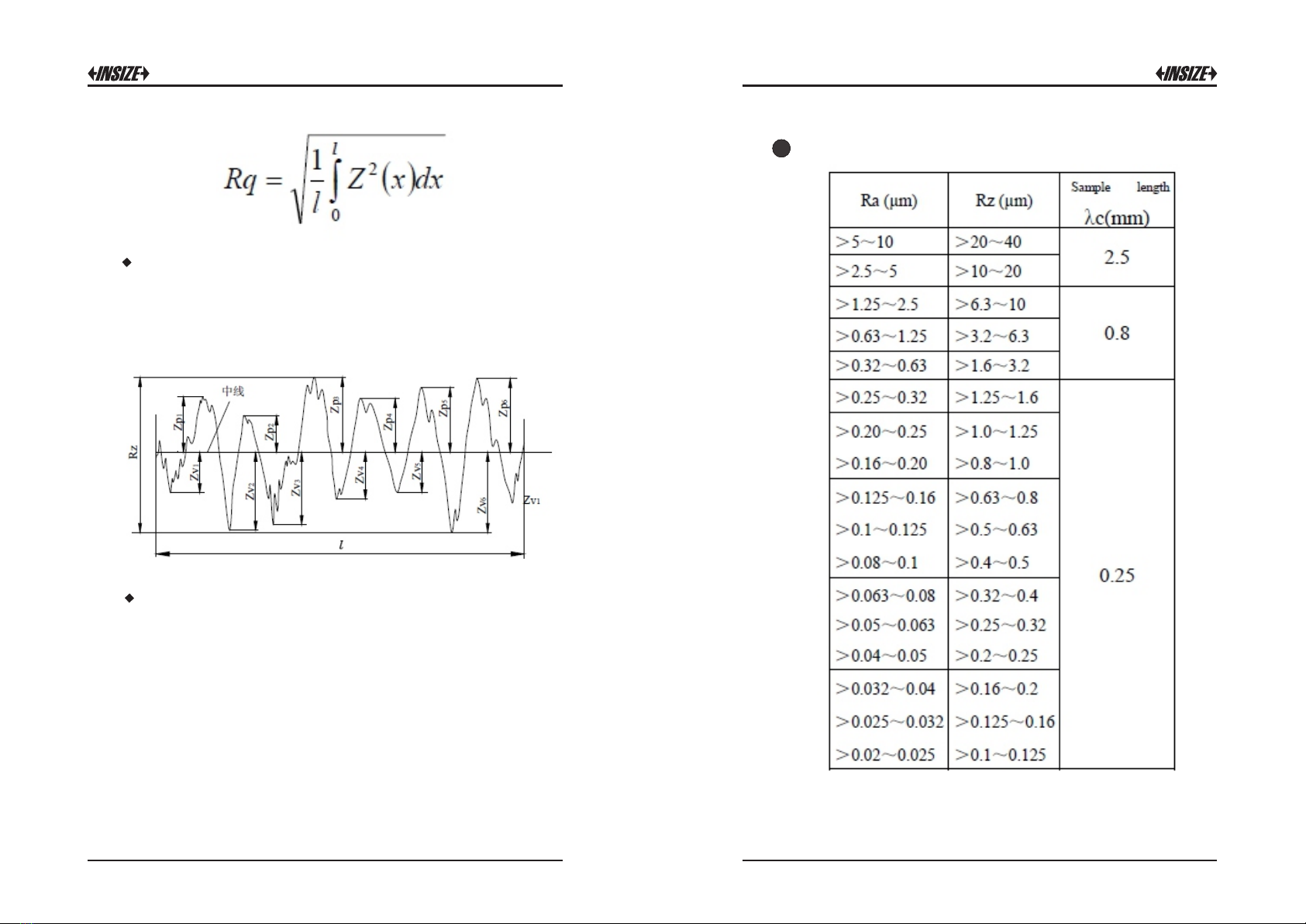

Root-mean-square Deviation of Profile Rq

Rq is the square root of the arithmetic mean of the squares of

profile deviation Z(x) from mean within sampling length.

11

12

29 30

Maximum Height of Profile Rz

Rz is The sum of height Zp of the highest profile peak from the

mean line and depth Zv of the deepest profile valley from the mean

line within sampling length。

Total Peak-to-valley Height Rt

Rt is the sum of the height of the highest peak Zp and the depth of

the deepest valley Zv over the evaluation length.

Recommended table of the sampling length

1113

Table of contents

Other insize Test Equipment manuals

insize

insize ISH-MRD200 User manual

insize

insize ISH-PHB User manual

insize

insize IST-TT Series User manual

insize

insize ISR-S300 User manual

insize

insize ISH-RD200 User manual

insize

insize IST-TT Series User manual

insize

insize ISHR-D121 User manual

insize

insize ISH-PHA User manual

insize

insize ISHR-P151 User manual

insize

insize ISHW User manual