8

1.5 Hazardous materials

1.6 Compliance

Consult material safety data sheets, packaging labels and the manufacturer or distributor

catalog before handling hazardous dispensing materials, such as ammable and

corrosive materials. Ensure any operators are informed of the material’s characteriscs

and compability with the dispensing unit. Always use appropriate safety equipment

and are. If you are unsure of a material’s compability, contact CELLINK.

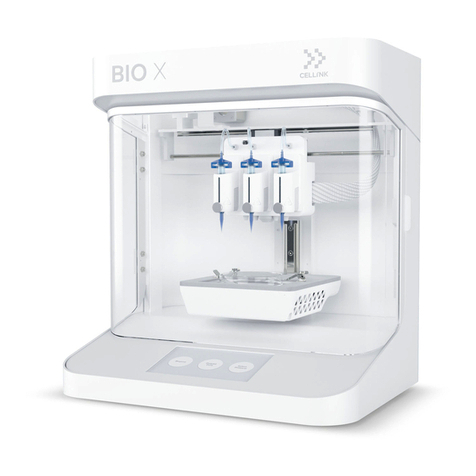

Aer using ethanol to clean BIO X, wait at least 60 seconds before bioprinng to

ensure that all ammable vapors are removed.

By using BIO X, you agree to the terms stated here and in the warranty (Chapter 6.) Except for

the express warranty set forth in the warranty informaon and in our soware license terms as

applicable, all equipment and soware provided hereunder are provided “as is,” and CELLINK makes

no warranty as to its use or performance. Except for any warranty, condion, representaon or term

the extent to which cannot be excluded or limited by applicable law, CELLINK and its suppliers make

no warranty, condion, representaon, or term (express or implied, whether by statute, common

law, custom, usage or otherwise) as to any maer including, without limitaon, noninfringement

of third party rights, merchantability, integraon, or tness for a parcular purpose. You assume

responsibility for selecng the soluon to achieve your intended results, and for the installaon

of, use of, and results obtained from the equipment and soware. Without liming the foregoing

provisions, CELLINK makes no warranty that the equipment or soware will be error-free or free from

interrupons or other failures or that the soware or equipment will meet your requirements. Under

no circumstances and under no legal theory, whether in tort, contract, or otherwise, shall CELLINK

or its suppliers be liable to purchaser or to any other person for loss of prots, loss of goodwill, or

any indirect, special, incidental, or consequenal damages, or damages for gross negligence of any

character. Under no circumstances can CELLINK be responsible for consequences of misuse of

the instrument or for use of the instrument outside the use specied in this user manual, be they

material or personal.