Intercomp CS200 User manual

Page 1 of 15

CS200

Users Manual

Intercomp Co.

3839 County Road 116

Medina, M 55340 U.S.A.

(763)-476-2531

1-800-328-3336

Fax: 763-476-2613

www.intercompcompany.com

Manual #: 700182-H

C 200, Users

August, 2009

2

Table of Contents

INTRODUCTION .......................................................................................................................................................3

SPECIFICATIONS .....................................................................................................................................................3

CONTROLS .................................................................................................................................................................3

ELECTRICAL...............................................................................................................................................................3

PERFORMANCE ..........................................................................................................................................................3

ENVIRONMENTAL ......................................................................................................................................................3

PHYSICAL ..................................................................................................................................................................3

OPERATIONS............................................................................................................................................................. 4

OPERATING PRACTICES..............................................................................................................................................4

CONTROLS .................................................................................................................................................................5

On/Off ..................................................................................................................................................................5

ZERO....................................................................................................................................................................5

Backlight ..............................................................................................................................................................5

Units Switching (lb and kg)..................................................................................................................................6

OPTIONS MENU ..........................................................................................................................................................6

Peak hold ode....................................................................................................................................................6

Print .....................................................................................................................................................................6

Sa ple Rate .........................................................................................................................................................6

Sleep.....................................................................................................................................................................7

Auto-off ................................................................................................................................................................7

Serial output.........................................................................................................................................................7

Baud Rate.............................................................................................................................................................7

MAINTENANCE.........................................................................................................................................................8

PERIODIC INSPECTION................................................................................................................................................8

Service Categories ...............................................................................................................................................8

Inspection Require ents......................................................................................................................................8

Re oval fro Service Criteria.............................................................................................................................9

CALIBRATION.............................................................................................................................................................9

How to test the calibration...................................................................................................................................9

How to enter a nu ber.......................................................................................................................................10

Calibration blocking switch ...............................................................................................................................10

How to calibrate the CS200 ...............................................................................................................................11

ERROR MESSAGES ................................................................................................................................................ 14

CHANGING THE BATTERY ........................................................................................................................................14

HOW TO REACH INTERCOMP ...........................................................................................................................15

"This document is the property of Intercomp Co. It contains material and

information that is confidential and protected under federal and/or state trade

secret, unfair competition, and copyright law. Any reproduction, use or disclosure

without written permission from Intercomp Co. is prohibited".

C 200, Users

August, 2009

3

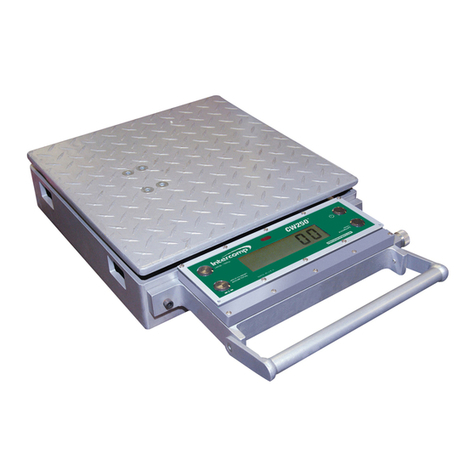

Introduction

This manual contains specifications and operation instructions for Intercomp's model

C 200 Crane cale.

Specifications

Controls

General: Zero, backlight, On/Off.

Display: 4 digit LCD.

Electrical

Batteries: 1 (9-volt) size disposable alkaline or rechargeable Nickel-

Cadmium cell.

Resolution: 14 bit A/D delivers over 16,000 internal counts..

Auto-Zero: Automatically zeros off errors of zero-load.

Battery life: 300 hours with an alkaline battery

20 hours with backlight on

Low battery indication:

Flashes “batt

battbatt

batt” when battery is running low; Turns off if

battery power is low enough to affect reliability.

Performance

Accuracy: ±0.1% of applied load or ± 1 display graduation, whichever is greater

Environmental

Humidity: 10 to 95% Non-Condensing.

Temperature:

Operating: -10 C to +50 C. / +15 F to +122 F.

torage: -40 C to +75 C. / -40 F to +170 F

Physical

Dimensions:

Height: 3.3" (6.2" with hooks) / 8.4cm (15.7cm with hooks)

Width: 4.4" / 11.2cm

Depth: 2.5" / 6.4cm

Weight: 1.1 lbs / 0.5 kg to 1.5 lbs / 0.7 kg depending on capacity

C 200, Users

August, 2009

4

Operations

Operating Practices

Warning: The crane scale will be operated by qualified designated persons, trainees

under the direct supervision of designated persons, maintenance and test personnel

when in performance of their assigned duties, or lifting device inspectors.

Warning: Do not exceed the rated load limit of the crane scale.

Warning: The crane scale shall be applied to the load in accordance with the

instruction manual.

Warning: Prior to lifting the operator shall make sure that all ropes or chains are not

kinked and if multiple lines are used they are not twisted around each other.

Warning: Ensure that the load is correctly distributed for crane scale use.

Warning: Ensure the temperature of the load does not exceed the maximum

temperature limits of the crane scale.

Warning: Ensure that swinging of the crane scale is minimized when positioning it over

the load.

Warning: Avoid any sudden acceleration of deceleration when moving the load.

Warning: Do not allow the crane scale or the lifter to come into contact with any

obstruction when moving the load.

Warning: Do not operate the crane scale if it has damaged, malfunctioning or missing

parts.

Warning: Do not lift people with the crane scale.

Warning: Do not lift suspended loads over people.

Warning: Do not use the crane scale to pull side loads or to slide loads unless

specifically authorized by a qualified person.

Warning: Do not leave suspended loads unattended.

Warning: Do not remove or obscure warning labels.

Warning: Do not operate the crane scale without having read and understood the

operating manual.

C 200, Users

August, 2009

5

Warning: tay clear of suspended loads.

Warning: Do not lift loads higher than necessary.

Warning: Do not make alterations or modifications to the crane scale.

Warning: Ensure all portions of the human body are kept clear of all device involved

with the rigging during the lift.

Controls

On/Off

Press this button to turn the C 200 on. The unit tests itself; when these tests

have completed successfully, the system begins weighing. Press this button

again to turn the unit off.

OTE: The scale will briefly display the firmware version when turning off.

ZERO

Tells the C 200 to display a zero weight. If you press ZERO with weight on the

pad, that weight becomes the zero condition for the scale. When this weight is

removed, a negative weight shows until the system is zeroed again.

OTE: if this negative number is too large to fit on the display, the scale will

display “dIS

dISdIS

dIS” until you press ZERO.

The scale contains a feature called Auto Zero Tracking (AZT), which corrects for

slight zero changes during normal operation. If small weights are added slowly,

the C 200 could zero them off.

Backlight

Press this key to toggle the backlight on and off.

C 200, Users

August, 2009

6

Units Switching (lb and kg)

The C 200 can toggle between lb and kg. To switch units simultaneously press

and hold the ZERO and backlight keys. After pressing and holding these keys

for a few seconds, the unit will momentarily display:

1) “kgS

kgSkgS

kgS”, if you have now switched to display in kgs.

2) “lbS

lbSlbS

lbS”, if you have now switched to display in lbs.

Options menu

The options menu allows access to the following functions: Peak mode, print, sample

rate, sleep mode, auto-off, serial output, and baud rate. To enter into the options menu,

simultaneously press the ZERO and backlight keys. The display will show “PEAk

PEAkPEAk

PEAk”.

Press the Zero or backlight keys to scroll through the menu options. To use or edit a

specific function, simultaneously press the ZERO and backlight keys. At this point you

will need to enter in a number:

How to enter a number:

Press the backlight key to increment the value of the blinking digit. To move the place

of the blinking digit, press the ZERO key. When the desired number is displayed,

simultaneously press the ZERO and backlight keys and release.

Peak hold mode

In this mode the unit will display only the highest force applied to the scale - until

you press the ZERO key.

To get into peak mode: Access the options menu. When the display shows

“PEAk

PEAkPEAk

PEAk”, simultaneously press the ZERO and backlight keys and release. The

tester will return to measurement mode and will display the peak force.

To return back to normal measurement mode, repeat the above procedure.

The unit will always turn on in “normal” operating mode.

Print

This feature is only applicable if you have the serial output version of the C 200.

To print: Access the options menu. Press ZERO until the display reads “Prnt

PrntPrnt

Prnt”.

The C 200 will print when you simultaneously press the ZERO and backlight

keys and release.

Sample Rate

The sample rate is the number of past readings that are averaged together to

make a reading. The default sample rate is 5.

C 200, Users

August, 2009

7

To adjust the sample rate: Access the options menu. Press ZERO until the

display reads “S rt

S rtS rt

S rt”. imultaneously press the ZERO and backlight keys and

release. Enter the sample rate. The display will momentarily display “SavE

SavESavE

SavE” and

return to normal mode.

Sleep

The sleep mode is designed to conserve battery life. The sleep mode time is

how long the scale's display will remain ON without any activity (a key being

pressed or a change in weight).

To adjust the sleep mode time: Access the options menu. Press ZERO until the

display reads “SLP

SLPSLP

SLP”. imultaneously press the ZERO and backlight keys and

release. Enter the sleep mode time (in minutes). To deactivate sleep, enter 0.

The maximum time is 180 minutes.

Auto-off

The auto off time is how long the scale will remain on without any activity (a key

being pressed or a change in weight).

To adjust the auto-off time: Access the options menu. Press ZERO until the

display reads “AOFF

AOFFAOFF

AOFF”. imultaneously press the ZERO and backlight keys and

release. Enter the auto-off time (in minutes). To deactivate auto-off, enter 0.

The maximum time is 180 minutes.

Serial output

This feature is only applicable if you have the serial output version of the C 200.

To turn on continuous serial output: Access the options menu. Press ZERO

until the display reads “SEr

SErSEr

SEr”. imultaneously press the ZERO and backlight keys

and release. Enter a “1” to activate serial output or “0” to deactivate.

Baud Rate

This feature is only applicable if you have the serial output version of the C 200.

When using serial output (this includes the print function), the baud rate must

match the peripheral device you are using.

To set the baud rate: Access the options menu. Press ZERO until the display

reads “bAud

bAudbAud

bAud”. imultaneously press the ZERO and backlight keys and release.

The following baud rates can be entered: 300, 600, 1200, 2400, 4800, 9600.

Default baud rate is 9600.

C 200, Users

August, 2009

8

Maintenance

Periodic Inspection

The crane scale and all associated adaptive devices require periodic inspection and

maintenance. The frequency and recording of the inspection requirements are found in

service categories below and are dependant on the type of service that the equipment

is used in as described below.

Service Categories

Normal ervice – Crane scale is operated at less than 85% of it’s capacity except for

isolated instances. Complete the frequent service inspection monthly and record the

periodic service inspection annually.

Heavy ervice – Crane scale is operated at 85% - 100% of it’s capacity as part of

normal usage. Complete the frequent service inspection weekly to monthly and record

the periodic service inspection semi-annually.

evere ervice – Crane scale is operated at 85% - 100% of it’s capacity and used in

environmental conditions that are unfavorable, harmful or detrimental to the use of the

crane scale. Complete the frequent service inspection daily to weekly and record the

periodic service inspection quarterly.

Inspection Requirements

Frequent Service Inspection (records not required)

A frequent visual inspection is completed at intervals indicated by the service category

above by the operator or designated person of the following.

1. Inspect for structural deformation, cracks or excessive wear of any part of the

crane scale or associated adaptive devices.

2. Inspect for loose or missing guards, fasteners, covers, stops, or nameplates.

3. Inspect all functional operating mechanisms and automatic hold and release

mechanisms for improper adjustments interfering with operation of the crane

scale or associated adaptive devices.

4. Inspect for distortion such as bending, twisting, or increased throat opening (if

applicable)

Periodic Service Inspection (records required)

A periodic visual inspection is completed at intervals indicated by the service category

above by the operator or designated person and documented to provide the basis for

continuing evaluation. The periodic inspection will cover areas in the frequent service

inspection above and the following.

1. Inspect for loose bolts or fasteners.

2. Inspect for cracked or worn gears, pulleys, sheaves, sprockets, bearings, chains,

and belts.

C 200, Users

August, 2009

9

3. Inspect for excessive wear of linkages and other mechanical parts.

4. Inspect for excessive wear at hoist hooking points and load support clevices or

pins.

5. Inspect for any visible bends or twists of all used rigging devices.

6. Inspect all latches and locks for proper operation (if applicable)

Removal from Service Criteria

Note: Replacement parts of any device or parts of any device used in any aspect of

rigging to lift a load shall be at least equal to the original manufacture’s specifications

Hooks

Hooks shall be removed from service if damage such as the following is found and shall

only be returned to service if a qualified person approves their continued use and

initiates corrective action.

1. Hooks show cracks, nicks, or gouges.

2. Hook has wear exceeding 10% of the original sectional dimension.

3. Hook has any visible bend or twist from the plane of the unbent hook.

4. Hook has an increase in throat opening of 5% not to exceed ¼ of an inch.

5. If self-locking hooks have the inability to lock.

6. A hook latch that is inoperable (if applicable)

Shackles

hackles shall be removed from service if damage such as the following is visible and

shall only be returned to service when approved by a qualified person.

1. If the manufacturers name or trademark and / or the rated load identification is

missing or illegible.

2. The device shows signs of heat damage including weld spatter or arc strikes.

3. The device shows excessive pitting or corrosion.

4. The device is bent, twisted, distorted, stretched, elongated, cracked, or has

broken load-bearing components.

5. The device has excessive nicks or gouges.

6. The device has a 10% reduction of the original or catalog dimension at any point

around the body or pin.

7. The device has incomplete pin engagement.

8. The device has excessive thread damage.

9. The device shows evidence of unauthorized welding.

10. Any other condition including visible damage that causes doubt to the continued

use of the shackle.

Calibration

How to test the calibration

This calibration procedure should be performed annually for normal operating

conditions. If the unit is dropped or damaged, or service has been performed on the

scale, use this calibration check. Recommend calibration points at 10% intervals from

C 200, Users

August, 2009

10

10% through 100% of the scales capacity.

Press the ON switch. The display does a lamp test; during this time the scale does a

quick check of itself. Then the weighing system starts weigh mode.

Intercomp recommends that you allow the electronics to operate for three minutes after

first turning power on. This allows the electronics to become stable for maximum

accuracy before you check the calibrations.

Make sure no weight is on the hook. Press the ZERO switch. The weight shown is zero.

Apply weights throughout the weighing range, and verify the correct weight is displayed

at each step. (+/- 0.1% of applied load or ±1 display graduation, whichever is greater)

If possible apply a weight of 105% of capacity, and verify the scale shows OVER on the

display.

Remove weights and verify the display returns to zero.

If there is a failure to meet any of the conditions above, please refer to the Calibration

Procedure.

When all the conditions above are correct, the scale is operational.

How to enter a number

During this routine you will be asked to enter numbers at many points. The scale will

show a number (originally all zeros) with a blinking digit. Press the ZERO key to

increase the value of the blinking digit. Press the BACKLIGHT key to move to other

digits. When you are finished entering the number press the ZERO and BACKLIGHT

keys together.

Three point span

This C 200 has a three point calibration feature which reduces the effects of non-

linearity in the load cells. This requires that you place three weights on the cell during

calibration. The first weight must be greater than zero, the second greater than the first,

and the final weight somewhere between the second and the capacity.

Calibration blocking switch

The calibration of the scale is protected from accidental change by a shunt placed on

pins 1 to 2 of CAL, located on the back of the circuit board. To allow calibration, the

shunt must be removed. When you are done calibrating, return the shunt to its original

location so that calibration is protected from change.

C 200, Users

August, 2009

11

How to calibrate the CS200

The following details the calibration procedure for the Intercomp C 200 crane scale.

There are four parameters that can be set before entering the actual calibration. When

changing a value, advance at least to “save

savesave

save” before turning off so that your changes are

saved.

Step Description ote Recommended

rd rt

rd rtrd rt

rd rt

Read rate 1 = 1 reads/sec

2 = 2 reads/sec

3 = 4 reads/sec

4 = 7 reads/sec

5 = 10 reads/sec

6 = 18 reads/sec

7 = 25 reads/sec

4

AZT

AZTAZT

AZT

Auto Zero Tracking 0 = disabled, 1,2,3 3

dely

delydely

dely

calibration delay 0 = no delay

1 = 7 second delay for cal

points

1

grad

gradgrad

grad

graduation 4 = 5 lb

5 = 2 lb

6 = 1 lb

7 = 0.5 lb

8 = 0.2 lb

9 = 0.1 lb

10 = 0.05 lb

11 = 0.02 lb

12 = 0.01 lb

cap

capcap

cap

capacity

save

cal

calcal

cal

calibration type 1 =1 point cal linear

0101 = 3 point cal

0101

LL00

LL00LL00

LL00

Zero read

LL01

LL01LL01

LL01

Cal load 1 Enter load 1

LL02

LL02LL02

LL02

Cal load 2 Enter load 2

LL03

LL03LL03

LL03

Cal load 3 Enter load 3

Start up.

1. Turn the power OFF.

2. Remove the calibration blocking shunt to allow entry into calibration mode.

3. Turn the power ON.

4. Wait for scale to warm up (3 minutes from power on).

5. Press ZERO and BACKLIGHT together and release to enter the calibration

mode.

The scale shows “rd rt

rd rtrd rt

rd rt”

. The read rate is the number of internal reads per

second the scale performs. A higher setting will result in a faster responding

C 200, Users

August, 2009

12

scale, but will also use the battery life more quickly. Press Zero until the desired

read rate is displayed. (see cal menu table above) Enter the read rate (1 to 7).

Press ZERO and BACKLIGHT together and release to enter the number

6. The scale shows “azt

aztazt

azt”. Press ZERO and BACKLIGHT together and release.

Enter (0) to turn the auto-zero tracking off, enter (1) to turn it on. When on, small

loads (+/- 3 divisions) will automatically be zeroed off after a few seconds. Press

ZERO and BACKLIGHT together and release to enter the number. Default = 1.

7. The scale shows “dELY

dELYdELY

dELY”. Press ZERO and BACKLIGHT together and release.

Enter (1) to turn the calibration delay on. If the delay is on: when the user

presses the keys to read a load point, there will be a 7 second delay until the

load point is actually read.

8. The scale shows “GrAd

GrAdGrAd

GrAd”. Press ZERO and BACKLIGHT together and release.

The scale shows the current graduation selection. Use the following table to

select a graduation value. Press ZERO and BACKLIGHT together and release to

enter the number.

etting

Count by in lb

Count by in kg

4 5 2

5 2 1

6 1 0.50

7 0.50 0.20

8 0.20 0.10

9 0.10 0.05

10 0.05 0.02

11 0.02 0.01

12 0.01 0.01

NOTE: The stated accuracy specifications are based on the graduation setting in

the table below. If the graduation setting is set other than the value in the table

below the accuracy specification remains with the graduation size listed below.

If your capacity is: Set your graduation to:

25 lb / 12.5 kg .01 lb / .01 kg (12)

50 lb / 25 kg .02 lb / .01 kg (11)

100 lb / 50 kg .05 lb / .02 kg (10)

250 lb / 125 kg .1 lb / 0.05 kg (9)

500 lb / 250 kg 0.2 lb / 0.1 kg (8)

9. The scale shows “CAP

CAPCAP

CAP”. Press ZERO and BACKLIGHT together and release.

Enter the scale's capacity in pounds.

At this point the gauge saves any changes that have been made

C 200, Users

August, 2009

13

Weight Calibration

10. The scale shows “CAL

CALCAL

CAL”. Press ZERO and backlight keys together and release.

The recommended calibration type is 3 point linear. Enter “0101”. Otherwise

enter “1” for a 1 point calibration.

11. The scale shows “LL00

LL00LL00

LL00”. With no weight on the pad, press ZERO and

BACKLIGHT together and release. This reads the pad zero.

12. The scale shows “LL01

LL01LL01

LL01”. Apply the first weight/force. Press the ZERO and

BACKLIGHT keys together and release. Then enter the value of the weight you

just applied. Press ZERO and BACKLIGHT together and release to enter this

number.

13. The scale shows “LL02

LL02LL02

LL02”. Apply the second weight. Press the ZERO and

BACKLIGHT keys together and release. Then enter the value of the weight you

just applied. Press ZERO and BACKLIGHT together and release to enter this

number.

14. The scale shows “LL03

LL03LL03

LL03”. Apply the third weight. Press the ZERO and

BACKLIGHT keys together and release. Then enter the value of the weight you

just applied. Press ZERO and BACKLIGHT together and release to enter this

number.

15. Return the calibration blocking shunt to it's original location to prevent accidental

entry into the calibration mode.

16. Verify the calibration.

17. Calibration complete.

C 200, Users

August, 2009

14

Error Messages

dISP

dISPdISP

dISP Display error, the scale is unable to display the number completely. If no

weight on the scale, press zero to return the weight reading to zero.

EEPE

EEPEEEPE

EEPE EEPROM error, the scale has had it's calibration corrupted or destroyed;

the scale will require calibration.

OE

OEOE

OE The scale is over capacity or outside the A/D converter range. Reduce the

load to the scale. If the C 200 continues to display “OE

OEOE

OE”, the problem

could be a bad load cell, bad load cell wiring, or a bad chip on the circuit

board.

OvEr

OvErOvEr

OvEr The C 200 is over capacity. Reduce the load on the pad.

BATT

BATTBATT

BATT Low battery, the unit requires a new battery. It will shut off if this message

is ignored for too long.

Changing the Battery

Turn the power off. lide the battery hatch down. Next, remove the battery from the

case and unsnap the used battery. nap in the new battery and replace the battery in

the case. Replace the cover.

C 200, Users

August, 2009

15

How to reach Intercomp

Things to know:

The service is for a C 200.

When did you purchase your C 200?

What is your serial number?

Whom did you purchase the C 200 through?

For Intercomp ervice call or fax:

FAX # (763)-476-2613

(763)-476-2531

1-800-328-3336

or fill out the ervice upport form at:

www.intercompcompany.com

Copyright Intercomp Company 2009

All rights reserved

Other manuals for CS200

1

Table of contents

Other Intercomp Scale manuals

Intercomp

Intercomp SW500 User manual

Intercomp

Intercomp PW800 User manual

Intercomp

Intercomp CS750 User manual

Intercomp

Intercomp CW250 User manual

Intercomp

Intercomp Microflex User manual

Intercomp

Intercomp CS750 User manual

Intercomp

Intercomp PT300 User manual

Intercomp

Intercomp CS1500 User manual

Intercomp

Intercomp LP600 User manual

Intercomp

Intercomp CW250 User manual