Intercomp Tension Link TL6000 User manual

TL6000 Tension Link

Users Manual

Intercomp Co.

3839 County Road 116

Minneapolis MN 55340

(763)-476-2531

1-800-328-3336

Fax: 763-476-2613

http://www.intercompcompany.com/

Manual #: 700169-L

TL6000, U er

Rev L, June 2008

Page 2 of 22

Table of Content

INTRODUCTION .......................................................................................................................................................3

SPECIFICATIONS .........................................................................................................................................................3

Controls................................................................................................................................................................3

Electrical..............................................................................................................................................................3

Performance.........................................................................................................................................................3

Environmental......................................................................................................................................................3

Radio....................................................................................................................................................................4

OPERATIONS.............................................................................................................................................................5

OPERATING PRACTICES..............................................................................................................................................5

DISPLAY ....................................................................................................................................................................6

CONTROLS .................................................................................................................................................................7

ON/OFF ...............................................................................................................................................................7

MODE ..................................................................................................................................................................7

PRINT.................................................................................................................................................................................... 8

UNITS.................................................................................................................................................................................... 8

SET P1, SET P2, Audio Al rm (option l) ............................................................................................................................. 8

SAMPLE RATE .................................................................................................................................................................... 9

SLEEP ................................................................................................................................................................................... 9

AUTO OFF .......................................................................................................................................................................... 10

SERIAL DATA OUT........................................................................................................................................................... 10

BAUD RATE....................................................................................................................................................................... 10

ANALOG OUT.................................................................................................................................................................... 11

SCALE ID............................................................................................................................................................................ 11

ZERO..................................................................................................................................................................11

T RE..................................................................................................................................................................12

PE K..................................................................................................................................................................12

POWER/BATTERIES ..................................................................................................................................................12

MAINTENANCE.......................................................................................................................................................13

PERIODIC INSPECTION..............................................................................................................................................13

Service Categories .............................................................................................................................................13

Inspection Requirements ....................................................................................................................................13

Removal from Service Criteria...........................................................................................................................14

CALIBRATION...........................................................................................................................................................14

How to test the calibration.................................................................................................................................14

How to enter a number.......................................................................................................................................15

Calibration Strap ...............................................................................................................................................15

How to calibrate the scale..................................................................................................................................16

Calibrating the weight accuracy........................................................................................................................18

ERROR MESSAGES ................................................................................................................................................19

TROUBLESHOOTING ............................................................................................................................................19

SERIAL OUTPUT.....................................................................................................................................................20

SCOREBOARD ..........................................................................................................................................................21

HOW TO REACH INTERCOMP SERVICE.........................................................................................................22

"Thi document i the property of Intercomp Co. It contain material and

information that i confidential and protected under federal and/or tate trade

ecret, unfair competition, and copyright law. Any reproduction, u e or

di clo ure without written permi ion from Intercomp Co. i prohibited".

TL6000, U er

Rev L, June 2008

Page 3 of 22

Introduction

Thi manual contain pecification , operation in truction , and calibration in truction

for Intercomp' model TL6000 ten ion link.

Specifications

Controls

General: On/Off, Mode, Zero, Peak, Tare

Di play: 1.2” 5 digit LCD.

Indicator : 9 di play icon

Electrical

Batterie : 1 or 2 tandard or Ni-Cad 9V cell

Battery life: Standard: Approximately 800 hour battery life on 2 Alkaline

cell , 400 hour on 1 Alkaline cell.

Wirele ver ion: 50 hour / 25 hour .

Re olution: 14 bit A/D deliver over 16,000 internal count

Filtering: Analog and digital

Sleep mode: Operate in low-power mode after adju table time without u e

or motion.

Auto off: Low battery, or after adju table time without u e or motion.

Auto Zero: Selectable 1, 2, or 3 graduation

Output : RS232, RS485, 0V-2V analog, 2 Set Point (3.3V logic level)

Optional cabled or wirele connection to a TL6000 Remote.

Performance

Accuracy: For capacitie 500 lb – 10,000lb: ±0.1% of applied load or ± 1

divi ion, whichever i greater.

For capacitie 25,000 lb and higher: ±0.2% of applied load or

± 2 divi ion , whichever i greater.

Environmental

Humidity: 10 to 95% Non-Conden ing.

Temperature: Operating: -10 C to +40 C / +14 F to +104 F.

Storage: -40 C to +75 C / -40 F to +170 F.

TL6000, U er

Rev L, June 2008

Page 4 of 22

Radio

Radio frequency

(US/Canada)

902 -928 MHz, 100mW max output power, FHSS

Radio frequency (Europe) 869.7 - 870 MHz, 5mW max output power, FSK

Licen e requirement None. Pre-approved US/FCC, CAN/IC, EUR/EN

Range 200’ / 60m indoor, 400’ / 120m line of ight

WARNING: Thi equipment ha been approved for mobile application

where the equipment hould be u ed at di tance greater than 20cm from

the human body (with the exception of hand , wri t , feet, and ankle .

Operation at di tance le than 20cm i trictly prohibited.

!

TL6000, U er

Rev L, June 2008

Page 5 of 22

Operations

Note If u ing your cale with a TL6000 remote: For be t operation with the remote,

et the Rd Rate to [3] ( ee ection ‘

First four parameters

’) and Sleep to [0] ( ee

ection ‘SLEEP’) on the TL6000 cale.

Operating Practices

Warning: The crane cale will be operated by qualified de ignated per on , trainee

under the direct upervi ion of de ignated per on , maintenance and te t per onnel

when in performance of their a igned dutie , or lifting device in pector .

Warning: Do not exceed the rated load limit of the crane cale.

Warning: The crane cale hall be applied to the load in accordance with the

in truction manual.

Warning: Prior to lifting the operator hall make ure that all rope or chain are not

kinked and if multiple line are u ed they are not twi ted around each other.

Warning: En ure that the load i correctly di tributed for crane cale u e.

Warning: En ure the temperature of the load doe not exceed the maximum

temperature limit of the crane cale.

Warning: En ure that winging of the crane cale i minimized when po itioning it over

the load.

Warning: Avoid any udden acceleration of deceleration when moving the load.

Warning: Do not allow the crane cale or the lifter to come into contact with any

ob truction when moving the load.

Warning: Do not operate the crane cale if it ha damaged, malfunctioning or mi ing

part .

Warning: Do not lift people with the crane cale.

Warning: Do not lift u pended load over people.

Warning: Do not u e the crane cale to pull ide load or to lide load unle

pecifically authorized by a qualified per on.

Warning: Do not leave u pended load unattended.

TL6000, U er

Rev L, June 2008

Page 6 of 22

Warning: Do not remove or ob cure warning label .

Warning: Do not operate the crane cale without having read and under tood the

operating manual.

Warning: Stay clear of u pended load .

Warning: Do not lift load higher than nece ary.

Warning: Do not make alteration or modification to the crane cale.

Warning: En ure all portion of the human body are kept clear of all device involved

with the rigging during the lift.

Display

TL6000, U er

Rev L, June 2008

Page 7 of 22

Controls

ON/OFF

Pre thi key to turn the cale on. The cale te t it elf; when the e te t have

completed ucce fully, the y tem begin weighing. Pre thi key to turn the

cale off.

MODE

Many of the internal parameter can be adju ted through the mode function.

There are a total of 12 mode : Backlight, Print, Unit , Set P1, Set P2, Sample

Rate, Sleep, Auto-off, Serial data output, Baud rate, Analog output, Scale ID.

Mode Description Notes Default

Print

PrintPrint

Print

Print ticket Hold MODE to print -

UnitS

UnitSUnitS

UnitS

Unit of weight lb, kg, daN, N, ton, kg x 1000 lb

SEtP1

SEtP1SEtP1

SEtP1

Set point 1 0 to 99999 99999

SEtP2

SEtP2SEtP2

SEtP2

Set point 2 0 to 99999 99999

S rt

S rtS rt

S rt

Sample rate 1 to 100 5

SLEEP

SLEEP SLEEP

SLEEP

Sleep mode 1 to 180 (min.) 0 = di able 5

AOFF

AOFFAOFF

AOFF

Auto off 1 to 180 (min.) 0 = di able 60

S Out

S OutS Out

S Out

Serial data out 0 = print (on-demand)

1 = continuou

3 = fa t continuou (variable)

0

Baud

BaudBaud

Baud

baud rate 300,600,1200,2400,4800,9600 9600

A OUT

A OUTA OUT

A OUT

analog out 0 = di able, 1 = enable 0

SC Id

SC IdSC Id

SC Id

cale ID 1 to 20 1

TL6000, U er

Rev L, June 2008

Page 8 of 22

Pre the MODE key to equentially toggle through the mode . To edit a mode

pre and hold the MODE key until the di play change . The value can be

changed by u ing the arrow keys:

↑ MODE

↓ TARE

← PEAK

→ ZERO

Plea e ee the information below for pecific in truction on editing each mode.

To ave the information you edited, pre and hold the MODE key until the

di play read ‘Save’. The TL6000 will then return to normal mea urement mode.

PRINT

Thi feature allow the net weight to be printed. See “Serial Output”

ection for more information.

To print ticket:

Press the MODE key until the display reads “Print

PrintPrint

Print”. Press and hold the

MODE key until the display reads “Print

PrintPrint

Print” again. The net weight will be

printed and the re ote returns to nor al operating ode.

UNITS

Mea urement can be taken in 6 different unit : lb (pound), kg (kilogram),

daN (DakaNewton), N (Newton), ton (Engli h ton), kg x1000 (Metric ton).

Changing Unit

Pre the mode key twice until the di play read ‘Units

UnitsUnits

Units’. Pre and hold

the MODE key until it read ‘Uedit

UeditUedit

Uedit’. Pre the left and right key (PEAK

and ZERO) to toggle through the unit of mea urement. The current unit

i di played on the bottom of the LCD. To ave the unit you want to

operate in pre and hold the MODE key until it read ‘Save

SaveSave

Save’. The TL6000

will return to mea urement mode.

Notes: If you change the units while a tare is set, the tare will be erased.

Changing units can affect the set points. If you are using the set

points, be sure to check the after changing units.

SET P1 SET P2 Audio Alarm (optional)

When the weight di played i equal to or greater than the et point, the

corre ponding indicator i di played on the LCD. The et point indicator

are the ‘S1’ and ‘S2’ icon located at the lower left corner of the di play.

Changing unit can affect the et point . If you are u ing the et point ,

be ure to re- et them after changing unit . There are et point output

ignal which can be utilized by u ing the connector located on the ide of

the TL6000. When Set Point #1 i reached, a logic ‘high’ will be pre ent

on pin 1 of the connector. When Set Point #2 i reached, a logic ‘high’ will

be pre ent on pin 2 of the connector.

TL6000, U er

Rev L, June 2008

Page 9 of 22

Note: If your scale has the optional audio alar , Set Point #1 and #2 are

not wired to the external connector. Instead, Set point #1 controls when

the alar will sound. The alar will sound whenever the weight applied to

the scale is greater than or equal to the weight entered into “Set P1”.

Changing Set Point

Pre the MODE button three time until the di play read ‘SEtP1

SEtP1SEtP1

SEtP1’. Pre

and hold the mode button until it read ‘Edit

EditEdit

Edit’. Change the value by u ing

the up/down, left/right (MODE/TARE, PEAK/ZERO) button . To ave the

et point pre and hold the MODE button until it read ‘SAvE

SAvESAvE

SAvE’. The

TL6000 will return to mea urement mode. To change Set Point 2, pre

the MODE button four time , until the di play read ‘SEtP2

SEtP2SEtP2

SEtP2’ and follow the

ame in truction a above in truction .

Default = 99999.

SAMPLE RATE

The higher the ample rate, the more averaging of pa t reading the

ten ion link u e to compute the di played weight. ‘1’ re ult in the

fa te t update time , while ‘100’ give you the mo t table read-out .

Changing the Sample rate:

Pre the MODE key five time until the di play read ‘S rt

S rtS rt

S rt ’. Pre and

hold the MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value by

u ing the arrow key . To ave the new ample rate pre and hold

MODE until the di play read ‘Save

SaveSave

Save’. The TL6000 will return to

mea urement mode.

Default = 5.

SLEEP

The TL6000 feature a low-power mode to con erve battery power. If the

cale doe not experience any activity for a predetermined amount of

minute , the y tem will witch to low -power mode. When in low power

mode, the cale till operate normally. The only difference i a lowed

re pon e rate. You may have to wait a econd or two for a change in

weight to how up on the di play. Any key pre ed or change in weight

will return the cale to normal mode.

Adju ting Sleep:

Pre the MODE key ix time until the di play read ‘SLEEP

SLEEPSLEEP

SLEEP’. Pre and

hold the MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value (in

minute ) u ing the arrow key . Any entry from 1 to 180 minute i

allowed. To di able the leep feature enter 0. To ave your data pre

and hold the MODE key until the di play read ‘Save

SaveSave

Save’. The y tem will

return to mea urement mode.

Default = 5.

TL6000, U er

Rev L, June 2008

Page 10 of 22

AUTO OFF

The TL6000 will automatically hut off if it doe not experience any

change in weight or key pre ed for a u er et amount of time.

Adju ting Auto Off:

Pre the MODE key even time until the di play read ‘AOFF

AOFFAOFF

AOFF’. Pre

and hold the MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value

(the unit i in minute ) u ing the arrow key . Any entry from 1 to 180

minute i allowed. To di able the auto off feature enter 0. To ave your

data, pre and hold the MODE key until the di play read ‘Save

SaveSave

Save’. The

y tem will return to mea urement mode.

Default = 60.

SERIAL DATA OUT

The TL6000 ha a RS232 and a RS485 output o the cale may be

connected to a printer, computer or other external device. See “Serial

Output” ection for more information.

Note: Serial data does not trans it during sleep ode.

Enabling/Di abling Serial data out:

Pre the MODE key until the di play read ‘S Out

S OutS Out

S Out ’. Pre and hold the

MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value u ing the

arrow key . “on-demand print” mean there will only be output when the

u er pre e print ( ee ‘PRINT’ ection for detail ). When et to

“continuou ”, there will be a continuou erial output at a rate of about 1

weight tran mi ion/ econd. When et to “fa t continuou (variable)”, the

tran mi ion rate can be much fa ter, varying from about 1 to 13 weight

tran mi ion / econd. In thi mode the rate varie depending on your

etting of “Read Rate” and “Baud Rate”. For the fa te t tran mi ion

rate et Read Rate=7 ( ee calibration ection) and Baud Rate = 9600

( ee below). Warning: In “fa t continuou ” mode, the unit’ di play will

update a fa t a it print . At the highe t etting thi can re ult in the

di play changing o fa t that it i ometime difficult to read.

On-demand print 0

continuou 1

fa t continuou (variable) 3

To ave your data, pre and hold the MODE key until the di play read

‘Save

SaveSave

Save’. The y tem will return to mea urement mode.

BAUD RATE

The baud rate i the frequency at which the erial data output i ent.

Operational baud rate : 300, 600, 1200, 2400, 4800, 9600.

TL6000, U er

Rev L, June 2008

Page 11 of 22

The default value for the baud rate i 9600 baud (bit / ec). Thi etting

only affect the printer output.

Changing the baud rate:

Pre the MODE key nine time until the di play read ‘b rt

b rtb rt

b rt ’. Pre and

hold the MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value u ing

the arrow key . To ave your data, pre and hold the MODE key until

the di play read ‘Save

SaveSave

Save’. The y tem will return to mea urement mode.

ANALOG OUT

Thi optional feature allow a 0V to 2V analog voltage that i panned

linearly by the applied weight to the ten ion link. The capacity the u er

et equal the maximum voltage level (2.0V) and no weight applied

equal 0V. All other voltage level will be linear (ratio metric) with the

weight value. For example, if the applied weight i ½ the capacity, the

voltage will be 1.0V. The analog output i utilized by the connector on the

ide of the cale.

Enabling or Di abling analog output

Pre the mode key ten time until the di play read “A Out

A OutA Out

A Out”. Pre and

hold the MODE key until the di play read ‘Edit

EditEdit

Edit’. Pre the up and down

key to change the etting. ‘1’ enable the analog out and ‘0’ di able the

analog out. To ave your data, pre and hold the MODE key until the

di play read ‘Sav

SavSav

Save

ee

e’. The y tem will return to mea urement mode.

Enable 1

Di able 0

SCALE ID

The cale ID parameter i u ed when you have a wirele TL6000

y tem. Each TL6000 cale mu t have a different cale ID (1 to 20).

Changing the cale ID:

Pre the MODE key until the di play read ‘SC Id

SC IdSC Id

SC Id ’. Pre and hold the

MODE key until the di play read ‘Edit

EditEdit

Edit’. Change the value u ing the

arrow key . To ave your data, pre and hold the MODE key until the

di play read ‘Save

SaveSave

Save’. The y tem will return to mea urement mode.

ZERO

Tell the cale to di play a zero weight. Thi key i u ed any time the cale

how a non-zero value with no weight on the cale. If you pre ZERO with

weight on the hook, that weight become the zero condition for the cale. Thi

can be u eful to cancel the weight of chain or cable . When thi weight i

removed, a negative weight how until the y tem i zeroed again.

The zero point i aved into memory. Thi mean you can turn the cale off and

TL6000, U er

Rev L, June 2008

Page 12 of 22

on with weight applied, o that the di played weight i the actual gro weight.

The cale contain a feature called Auto Zero Tracking (AZT), which correct

for light zero change during normal operation. If the AZT i enabled and mall

weight are added lowly, the cale could zero them off.

TARE

Pre ing the TARE key will et the tare equal to the current gro weight and

witch the di play to net weight. The di play will read ‘nEt

nEtnEt

nEt’ when the TARE

button i relea ed. The net weight i equal to the gro weight minu the tare

weight. The tare weight will only be et if the current gro weight i po itive.

Displaying the tare weight:

If a tare weight i et, pre ing the TARE key will di play the current value

of the tare. The tare will be di played a long a you hold the key.

Clearing the tare:

Pre ing the ZERO and TARE key together will re et the tare to zero.

The di play will read ‘GroSS

GroSSGroSS

GroSS’ when the key are relea ed. Thi ignifie

that the cale will now di play gro weight, which i equal to the net

weight when tare = 0.

PEAK

The peak hold feature will remember the maximum weight applied. While in peak

mode it will not di play any weight le than the maximum weight. To turn on the

peak mode pre PEAK, to turn off the peak mode pre PEAK again. To clear

the peak weight, pre the ZERO key.

Note: When you turn off the peak ode, the current peak weight will still be

re e bered internally. This will show up if you then turn the peak ode back

on. Press ZERO (or turn the scale off) to clear the peak weight.

Power/Batteries

Remove the two crew on the ide of the unit (either ide). Replace the 9V battery.

Replace the cover.

You may u e rechargeable Nickel-Cadmium 9V cell or tandard alkaline 9V cell in the

TL6000. Note: Only one 9V battery i required to run the TL6000. The econd 9V

battery will double the ob erved battery life.

The typical recharge time for Ni-cad cell i 16 hour . The rechargeable batterie have

a life pan up to 1000 cycle .

TL6000, U er

Rev L, June 2008

Page 13 of 22

Maintenance

Periodic Inspection

The crane cale and all a ociated adaptive device require periodic in pection and

maintenance. The frequency and recording of the in pection requirement are found in

ervice categorie below and are dependant on the type of ervice that the equipment

i u ed in a de cribed below.

Service Categories

Normal Service – Crane cale i operated at le than 85% of it’ capacity except for

i olated in tance . Complete the frequent ervice in pection monthly and record the

periodic ervice in pection annually.

Heavy Service – Crane cale i operated at 85% - 100% of it’ capacity a part of

normal u age. Complete the frequent ervice in pection weekly to monthly and record

the periodic ervice in pection emi-annually.

Severe Service – Crane cale i operated at 85% - 100% of it’ capacity and u ed in

environmental condition that are unfavorable, harmful or detrimental to the u e of the

crane cale. Complete the frequent ervice in pection daily to weekly and record the

periodic ervice in pection quarterly.

Inspection Requirements

Frequent Service Inspection (record not required)

A frequent vi ual in pection i completed at interval indicated by the ervice category

above by the operator or de ignated per on of the following.

1. In pect for tructural deformation, crack or exce ive wear of any part of the

crane cale or a ociated adaptive device .

2. In pect for loo e or mi ing guard , fa tener , cover , top , or nameplate .

3. In pect all functional operating mechani m and automatic hold and relea e

mechani m for improper adju tment interfering with operation of the crane

cale or a ociated adaptive device .

4. In pect for di tortion uch a bending, twi ting, or increa ed throat opening (if

applicable)

Periodic Service Inspection (record required)

A periodic vi ual in pection i completed at interval indicated by the ervice category

above by the operator or de ignated per on and documented to provide the ba i for

continuing evaluation. The periodic in pection will cover area in the frequent ervice

in pection above and the following.

1. In pect for loo e bolt or fa tener .

2. In pect for cracked or worn gear , pulley , heave , procket , bearing , chain ,

and belt .

3. In pect for exce ive wear of linkage and other mechanical part .

TL6000, U er

Rev L, June 2008

Page 14 of 22

4. In pect for exce ive wear at hoi t hooking point and load upport clevice or

pin .

5. In pect for any vi ible bend or twi t of all u ed rigging device .

6. In pect all latche and lock for proper operation (if applicable)

Removal from Service Criteria

Note: Replacement part of any device or part of any device u ed in any a pect of

rigging to lift a load hall be at lea t equal to the original manufacture’ pecification

Hooks

Hook hall be removed from ervice if damage uch a the following i found and hall

only be returned to ervice if a qualified per on approve their continued u e and

initiate corrective action.

1. Hook how crack , nick , or gouge .

2. Hook ha wear exceeding 10% of the original ectional dimen ion.

3. Hook ha any vi ible bend or twi t from the plane of the unbent hook.

4. Hook ha an increa e in throat opening of 5% not to exceed ¼ of an inch.

5. If elf-locking hook have the inability to lock.

6. A hook latch that i inoperable (if applicable)

Shackles

Shackle hall be removed from ervice if damage uch a the following i vi ible and

hall only be returned to ervice when approved by a qualified per on.

1. If the manufacturer name or trademark and / or the rated load identification i

mi ing or illegible.

2. The device how ign of heat damage including weld patter or arc trike .

3. The device how exce ive pitting or corro ion.

4. The device i bent, twi ted, di torted, tretched, elongated, cracked, or ha

broken load-bearing component .

5. The device ha exce ive nick or gouge .

6. The device ha a 10% reduction of the original or catalog dimen ion at any point

around the body or pin.

7. The device ha incomplete pin engagement.

8. The device ha exce ive thread damage.

9. The device how evidence of unauthorized welding.

10. Any other condition including vi ible damage that cau e doubt to the continued

u e of the hackle.

Calibration

How to test the calibration

Thi calibration procedure hould be performed annually for normal operating

condition . If the cale i dropped or damaged, or ervice ha been performed on the

cale, u e thi calibration check. Recommend weight from 10% through 100% of cale

capacity in 10% increment .

TL6000, U er

Rev L, June 2008

Page 15 of 22

1. Pre the ON witch. The di play doe a lamp te t; during thi time the cale doe a

quick check of it elf. Then the weighing y tem tart weigh mode.

2. Intercomp recommend that you allow the electronic to operate for three minute

after fir t turning the power on. Thi allow the electronic to become table for

maximum accuracy before you check the calibration .

3. Make ure no weight i on the hook. Pre the ZERO key. Pre the TARE and

ZERO key to clear tare. The weight hown i zero.

4. Apply weight throughout the weighing range, and verify the correct weight i

di played at each tep. (+/- 0.1% of applied load or ± 1 divi ion, whichever i greater

for cale 500 – 10000 lb and ±0.2% of applied load or ± 2 divi ion , whichever i

greater for cale 25000 lb or greater)

5. Remove weight and verify the di play return to zero.

6. If there i a failure to meet any of the condition above, plea e refer to the

Calibration Procedure.

7. When all the condition above are correct, the cale i operational.

How to enter a number

During thi routine you will be a ked to enter number at many point . The cale will

how a number (originally all zero ) with a blinking digit. At thi point the command li ted

at the ide of the key become active. Pre the UP and DOWN arrow key to increa e

and decrea e the blinking digit. Pre the LEFT and RIGHT arrow key to move to other

digit . Pre the ZERO and PEAK key together to ave the value and advance to the

next parameter.

Five point span

The cale ha a five point calibration feature that reduce the effect of non-linearity in

the load cell . Thi require that you place five weight on the cell during calibration.

The fir t weight mu t be greater than zero, the econd greater than the fir t, the third

greater than the econd, the fourth greater than the third, and the final weight

omewhere between the fourth and the capacity. To u e le than five calibration

point , turn the cale off before reading the next cal point.

Calibration Strap

The calibration header that u e the calibration horting trap i located on the bottom

ide of the circuit board (oppo ite ide of the di play). Thi 90° header i labeled CAL.

Enabling the calibration.

The fir t four parameter may be edited with or without the calibration trap. To

perform the actual weight calibration, you mu t remove the calibration blocking

trap. Remove the 4 crew on the back plate of the ten ion link. Remove back

plate. The calibration header i located on the lower right corner of the circuit

board. Remove the black horting trap and lide it on one of the pin (for

convenience). Screw the back plate back on.

TL6000, U er

Rev L, June 2008

Page 16 of 22

How to calibrate the scale

The following detail the calibration procedure for the ten ion cale. All parameter can

be et without the calibration trap. If the cal trap i in place, only the fir t four

parameter may be calibrated.

Step Function Note

Default

rd rt

rd rtrd rt

rd rt

Read Rate 1 to 7 ( ee table) 4

Azt

AztAzt

Azt

Auto Zero Tracking 0=off, 1=1, 2=2, 3=3 3

GrAd

GrAdGrAd

GrAd

Graduation 0 to 12 ( ee table) 6

CAP

CAPCAP

CAP

Capacity Enter Capacity

Information aved

Check Cal Strap

LOAd0

LOAd0LOAd0

LOAd0

Zero Read No weight applied

LOAd1

LOAd1LOAd1

LOAd1

Fir t weight Enter fir t weight

LOAd2

LOAd2LOAd2

LOAd2

Second weight Enter econd weight

LOAd3

LOAd3LOAd3

LOAd3

Third weight Enter third weight

LOAd

LOAdLOAd

LOAd

Fourth weight Enter fourth weight

LOAd5

LOAd5LOAd5

LOAd5

Fifth weight Enter fifth weight

Start up

Note: Read section titled: How to enter a nu ber

1) Turn cale power ON.

2) Wait for cale to warm up (3 minute from power on).

3) Pre ZERO and PEAK together and relea e to enter the calibration mode.

First four parameters

4) The cale how ‘rd rt

rd rtrd rt

rd rt ’. The read rate i the number of internal read per

econd the cale perform . A higher etting will re ult in a fa ter re ponding

cale, but will al o u e the battery life more quickly. Pre ZERO and PEAK

together to edit the read rate. Enter the read rate (1 to 7).

Note: When you plan to connect the TL6000 to a cabled or wireless TL6000

re ote, set the read rate to (3) or less for best results.

Read Rate Readings / sec

1 1

2 2

3 4

4 7

5 10

6 18

7 25

TL6000, U er

Rev L, June 2008

Page 17 of 22

Note: If the “Serial Out” etting in your unit i et to “3 = fa t continuou ” then

the above read rate will be lower becau e of the time the cale pend

tran mitting data out the erial port.

5) The cale how ‘AZt

AZtAZt

AZt ’. Pre ZERO and PEAK together to edit the Auto

Zero Tracking. Enter the AZT ize (0 to 3 divi ion ). AZT i the number of

graduation the auto zero tracking can remove. An entry of ‘0’ di able the

feature.

6) The cale how ‘GrAd

GrAdGrAd

GrAd’. Pre ZERO and PEAK together to edit the

Graduation . U e the following table to elect and enter a graduation value.

Graduations and Units

Grad Setting

lb Kg N daN ton kg x 1000

0 100 50 100 50 0.05 0.05

1 50 20 100 20 0.02 0.02

2 20 10 100 10 0.01 0.01

3 10 5 50 5 0.005 0.005

4 5 2 20 2 0.002 0.002

5 2 1 10 1 0.001 0.001

6 1 0.5 5 0.5 0.0005 0.0005

7 0.5 0.2 2 0.2 0.0002 0.0002

8 0.2 0.1 1 0.1 0.0001 0.0001

9 0.1 0.05 0.5 0.05

10 0.05 0.02 0.2 0.02

11 0.02 0.01 0.1 0.01

12 0.01 0.005

0.05 0.005

Note: Grads 9-12 do not exist for ton and kg x1000.

NOTE: The tated accuracy pecification are ba ed on the graduation etting in

the table below. If the graduation etting i et other than the value in the table

below the accuracy pecification remain with the graduation ize li ted below.

If your capacity is: Set your graduation to:

1000 lb / 500 kg 1 lb / 0.5 kg (6)

2000 lb / 1000 kg 2 lb / 1 kg (5)

5,000 lb / 2,500 kg 5 lb / 2 kg (4)

10,000 lb / 5,000 kg 10 lb / 5 kg (3)

25,000 lb / 12,500 kg 20 lb / 10 kg (2)

50,000 lb / 25,000 kg 50 lb / 20 kg (1)

100,000 lb / 50,000 kg 100 lb / 50 kg (0)

7) The cale how ‘CAP

CAPCAP

CAP’. Pre ZERO and PEAK together to edit the Capacity.

Enter the capacity. Pre the ZERO and PEAK key together to ave the

data and the di play will read ‘SAvE

SAvESAvE

SAvE’.

TL6000, U er

Rev L, June 2008

Page 18 of 22

Calibrating the weight accuracy

Note: At this ti e the scale saves any changes that have been ade.

Note: A check is then ade to see whether or not the calibration blocking strap

is in place. If the blocking strap is in place, the scale shows ‘CALSt

CALStCALSt

CALSt’ for a few

seconds and then returns to nor al weighing.

8) A uming the calibration trap wa removed, the di play will read ‘L0Ad0

L0Ad0L0Ad0

L0Ad0’.

With no weight applied to the cale, pre ZERO and PEAK together.

9) The di play will read ‘L0Ad1

L0Ad1L0Ad1

L0Ad1’. Apply the fir t weight. When the weight i

table pre one of the arrow key . The di play will read ‘H0Ld

H0LdH0Ld

H0Ld’ while the

cale acquire the fir t weight. After thi , enter the value of the applied

weight. Pre ZERO and PEAK together to ave the value and advance to

Load 2.

10) The di play will read ‘L0ad2

L0ad2L0ad2

L0ad2’. Apply the econd weight. When the weight i

table pre one of the arrow key . The di play will read ‘H0Ld

H0LdH0Ld

H0Ld’ while the

cale acquire the econd weight. After thi , enter the value of the applied

weight. Pre ZERO and PEAK together to ave the value and advance to

Load 3.

11) The di play will read ‘L0Ad3

L0Ad3L0Ad3

L0Ad3’. Apply the third weight. When the weight i

table pre one of the arrow key . The di play will read ‘H0Ld

H0LdH0Ld

H0Ld’ while the

cale acquire the third weight. After thi , enter the value of the applied

weight. Pre ZERO and PEAK together to ave the value. The di play will

read ‘SAvE

SAvESAvE

SAvE’ for a few econd and advance to Load 4.

12) The di play will read ‘L0Ad

L0AdL0Ad

L0Ad ’. Apply the fourth weight. When the weight i

table pre one of the arrow key . The di play will read ‘H0Ld

H0LdH0Ld

H0Ld’ while the

cale acquire the third weight. After thi , enter the value of the applied

weight. Pre ZERO and PEAK together to ave the value. The di play will

read ‘SAvE

SAvESAvE

SAvE’ for a few econd and advance to Load 5.

13) The di play will read ‘L0Ad5

L0Ad5L0Ad5

L0Ad5’. Apply the fifth weight. When the weight i

table pre one of the arrow key . The di play will read ‘H0Ld

H0LdH0Ld

H0Ld’ while the

cale acquire the third weight. After thi , enter the value of the applied

weight. Pre ZERO and PEAK together to ave the value. The di play will

read ‘SAvE

SAvESAvE

SAvE’ for a few econd and return to mea urement mode.

14) Verify calibration.

15) Replace the cal trap to protect again t accidental entry into the calibration

routine in the future.

16) Calibration complete.

TL6000, U er

Rev L, June 2008

Page 19 of 22

Error Messages

OvER

OvEROvER

OvER

The cale i over capacity. Reduce the weight applied to the cale.

OE

OEOE

OE

The cale i out ide the internal A/D converter range. Reduce the weight

applied to the cale.

dISP

dISPdISP

dISP

Di play error. Value i too large to fit on the di play. Reduce the weight

applied to the cale, or try changing graduation .

-dISP

-dISP-dISP

-dISP

Di play error. Value i too negative to fit on the di play. Pre ZERO to

zero the cale.

EEPE

EEPEEEPE

EEPE

EEPROM error. The cale ha had it’ calibration corrupted or de troyed;

the cale will require calibration.

Err 1

Err 1Err 1

Err 1

Error during calibration. The cale automatically exit calibration mode.

When calibrating, make ure that each of the three calibration weight i

larger than the previou weight.

Err 2

Err 2Err 2

Err 2

EEPROM error. The cale i unable to read the EEPROM.

Err

Err Err

Err

EEPROM error. The cale i unable to write to the EEPROM.

CALSt

CALStCALSt

CALSt

Thi me age will how for a few econd if you have attempted to acce

weight calibration with the calibration trap in place. See the “Calibration”

ection if you need to calibrate.

Troubleshooting

Problem: Solution:

Di play freeze or i blank and no

re pon e to key pre ed

The MCU may have locked up. Try

removing both batterie together, and then

replacing one or both of them. A a

general rule to reduce lock-up , whenever

turning the TL6000 off, wait at lea t 5-10

econd before turning it on again.

Batterie are good but the cale won’t

power up.

If the cale i turned off and turned back

on right away, the cale may not be able to

power up. Wait about 10 econd after

powering off before pre ing the ON key

again.

TL6000, U er

Rev L, June 2008

Page 20 of 22

Serial Output

The TL6000 can be et to output (continuou ) to a coreboard or other external device

u ing RS232 or RS485 format . See mode menu / erial data out. The TL6000 can

al o tran mit and receive RS232 ignal (continuou ) to communicate with a Ten ion

Link remote. The TL6000 can al o be et to output (on demand) to a printer.

The ignal come out of the 8-pin Serial I/O connector located on the right ide of the

unit. The connector ha the following pinout:

Signal Pin

RS232-TXD1 (remote) 3

RS232-TXD2 (printer/ coreboard) 4

RS232-RXD 5

GND 6

RS485-A (printer/ coreboard) 7

RS485-B (printer/ coreboard) 8

Set Point #1 (3.3V logic level) 1

Set Point #2 (3.3V logic level) 2

NOTE: If your scale has the wireless option, pins 3 & 5 will be unconnected internally.

The tran mitted erial data ha the following characteri tic :

Fixed 8 Data bit , no parity, 1 top bit.

Baud rate i configurable. See Mode ection.

The RS232 output wing from -6 VDC to 6 VDC.

Table of contents

Other Intercomp Scale manuals

Intercomp

Intercomp CS750 User manual

Intercomp

Intercomp CS3000 User manual

Intercomp

Intercomp CS200 User manual

Intercomp

Intercomp Microflex User manual

Intercomp

Intercomp SW500 User manual

Intercomp

Intercomp PT300 User manual

Intercomp

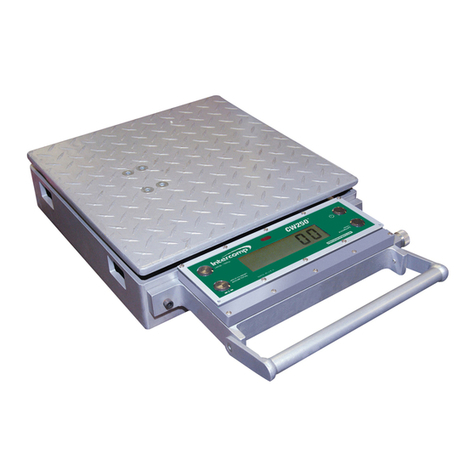

Intercomp CW250 User manual

Intercomp

Intercomp CS200 User manual

Intercomp

Intercomp PW800 User manual

Intercomp

Intercomp CW250 User manual