Residential Installation

Page 4

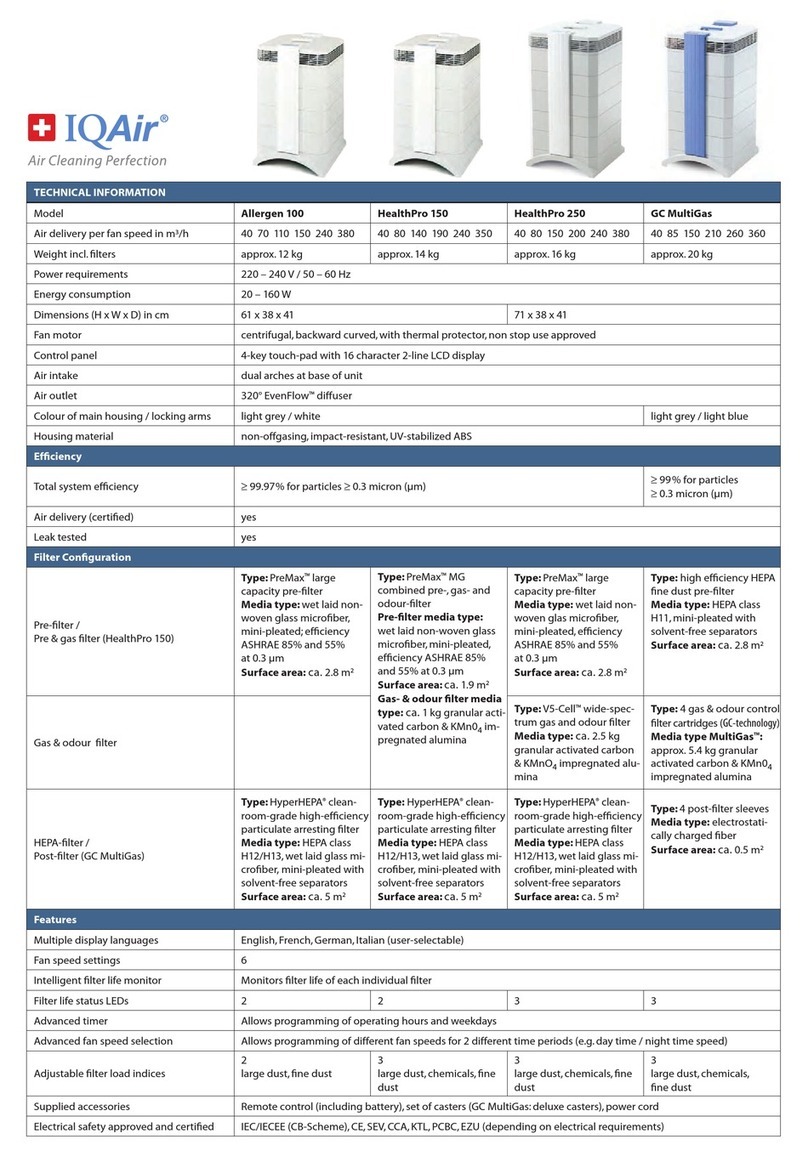

ID-2225 System ID-2530 System

inch

mm

25.25 x 21.25 x 21.25

642 x 540 x 540

29.25 x 25.25 x 21.25

743 x 642 x 540

Weight 59 lbs. (27 kg) 74 lbs. (33.5 kg)

Order No. 207 80 21 02 207 80 21 04

Dimension L x W x H

ID-2225 Replacement Filter Set ID-2530 Replacement Filter Set

SIZE 3 SIZE 4

Order No. 202 11 30 02 (Filter Set, 4 count) 202 11 30 03 (Filter Set, 4 count)

Residential Installation

The Perfect 16 ID-Series can be suspended from exposed ceiling joists or the ceiling surface. Alternatively, it can be floor-

mounted (see page 5 for installation options).

1. Choose a location between the main return duct and the furnace, which is readily accessible for checking and replacing

the filter. Allow at least 24.5 in. (622 mm) clearance in front of the ID-2225 and 28.5 in. (724 mm) clearance in front of the

ID-2530.

2. Adapt connection panel for duct air handler connection as necessary (see page 4). Best performance is achieved with

the 16”x 20” opening for the ID-2225 model, and the 20”x 25” opening for the ID-2530. If flex duct is used, it is strongly

recommended to use 18” round dove tail collar for the ID-2225 and 20” for the ID-2530 for best performance.

3. Determine the correct air inlet and air outlet side of the system. The air inlet is marked with “Cut this Panel for Duct

Connection - DI TY AI IN”. The air outlet is marked with “Cut this Panel for Duct Connection - CLEAN AI OUT”.

Both panels will need to be cut for the proper fit of the ducting prior to installation.

4. If the Perfect 16 system is to be located immediately alongside the furnace, remove filters and secure cabinet via panel

from inside to the furnace with sheet metal screws. Ensure correct airflow direction when reinserting filters.

5. In basement installations, sheet metal turning vanes may be necessary to improve air movement through an elbow in

the duct.

6. Use foil tape to seal all duct joints. Note: All leaks on the return side of the system will cause dirty air to leak into the

return air stream. Leakage also occurs in many furnaces via the blower door. The blower door should also be sealed

with foil tape for the best air cleaning results.

7. Fill out the filter replacement label with the date of the next scheduled filter replacement, which should be no later than 3

years from the current date (based on 50% usage).

8. Check and inspect system for leakage.

9. Test for efficiency with a ParticleScan.