D4™ Rope adjustment device.

General

Responsibility

Compatibility

Always ensure that all components within

a safety system are compatible and allow

the system to function safely.

Use Inspection

Use Requirements

Testing

All testing for this device at ISC and the

EN1891 approved ropes Ø10.5mm -

11.5mm rope. Suitable for rescue loads

up to 240kg.

Modifications, repair

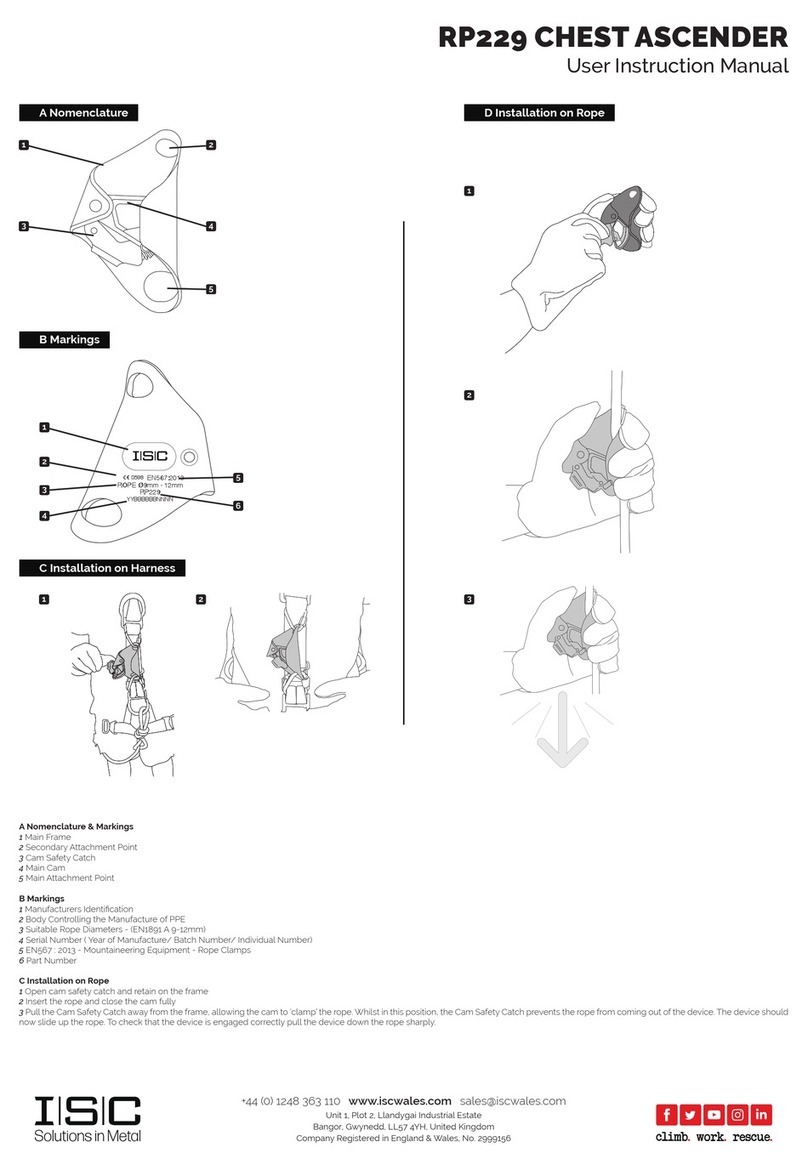

Figure 1 –Installation

Figure 3 –Operational check

Use

To control the device in descent, your left

hand is used to position the handle, and

your right hand is used on the trailing

length of rope to give you extra security

and fine adjustments of speed control. If

in the situation that you pull the handle

too far the device will STOP. To RESET

the device rotate the handle clockwise, in

the direction of the arrows. This will

allow you to continue to DESCEND. All

rope adjustment devices create heat

when travelling along rope at speed,

which can cause damage to the rope.

Always check the rope for damage as well

as the device.

Storage & Transportation

The product should be stored in a clean,

dry environment away from exposure to

UV, corrosive or chemical substances or

extreme heat sources. Care should be

taken to protect the product against

damage during transportation.

Product Inspection & Maintenance

In addition to the visual inspections (see

Inspection) a thorough examination

should be carried out by a competent

person in line with applicable legislation

withdrawn from use and not used again

until confirmed in writing by a competent

person that it is safe to do so, should any

doubt arise about its condition for safe

use or, if it has been used to arrest a fall.

The

potential lifetime of ISC products is up to 10

years for plastic or textile products, and indefi-

nite for metal products. The actual lifetime of a

product depends on a variety of factors such

as, the intensity of use, the frequency of use,

the environment in which it has been used, the

competency of the user, and how well it has

been maintained and stored etc.

Cleaning

The product must be cleaned regularly

(or after every use in a marine

environment) with a mild detergent.

Afterwards the product should be rinsed

in clean water and allowed to dry

naturally. Alternatively an air gun can be

used to clear debris from device. Moving

parts may be oiled regularly with a light

oil such as 3-in-1.

Manufacturers’ responsibility

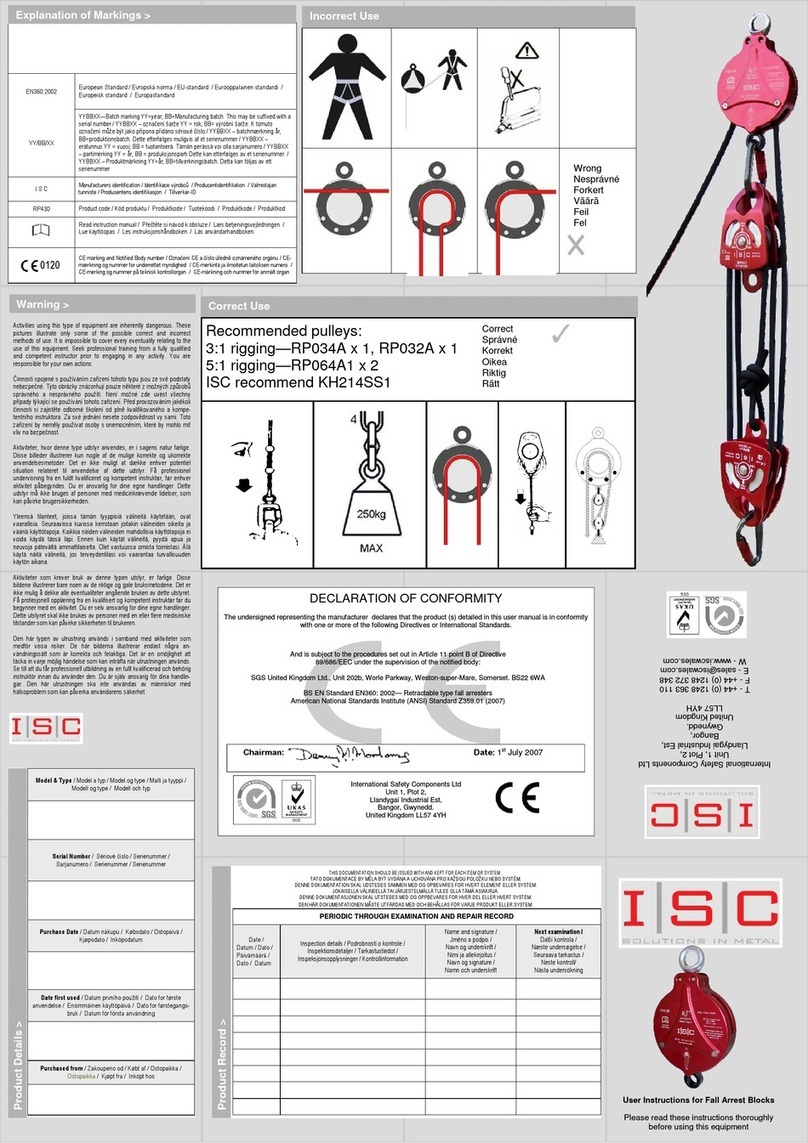

Approvals –Declaration of Conformity

The D4™ rope adjustment device is man-

ufactured by ISC Llandygai Ind Est., Ban-

gor, Gwynedd. LL57 4YH and has been

tested and approved by SATRA Tech-

nology Centre, Wyndham Way, Telford

Way, Kettering. NN16 8SD., notified

body number 0321, in accordance

with EN12841:2006 with a maximum rat-

ed load of 240kg and is subject to the

procedures set out in Article 11b of Di-

rective 89/686/EEC under the supervi-

sion of SGS UK Ltd., Unit 202b, Worle

Parkway, Weston-super-mare. BS22

6WA., notified body number 0120.

For further information please visit our

youtube page :

http://www.youtube.com/user/iscmarketing

RP880 series RP880UIM :Issue D: Sept 2015